- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper bars

Results for

Copper bars - Import export

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Beside Our exsisting wide range, we also develop profiles as per customers requirments.They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380. They are used in following main applications: Automobiles and railways Wide range of uses in electrical industry, e.g. switchgears, earthing rods etc. Transformers and circuit breaker terminals Electrical holders and clamps Defence industries etc.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Beside Our exsisting wide range, we also develop profiles as per customers requirments.They are according with DIN EN 1057, DIN EN 13348, DIN EN 13600, ASTM B280, ASTM B68, ASTM B75, TS 380. They are used in following main applications: Automobiles and railways Wide range of uses in electrical industry, e.g. switchgears, earthing rods etc. Transformers and circuit breaker terminals Electrical holders and clamps Defence industries etc.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc. They are produced OF upward cansting than Contunious processing and drawing.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper or aluminum, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc.

Request for a quote

EID

France

8 multi-diameter bypasses Copper for brazing: Black insulation: Black insulation BL-s3,d0 (M1) 13MM Bend: MSH85 only

Request for a quote

EID

France

Fluids R22 & R407 Seal-break couplers With copper tube 150mm-long to facilitate brazing Screw together, Male or Female 1/4 SAE With or without pressure gauge pick-off. Brass for brazing (PE)

Request for a quote

EID

France

Allows two precharged systems to be coupled when screwed together. Unions are tightened with two spanners, until the 2 seals, male and female, are broken.

Request for a quote

EID

France

Allows two precharged systems to be coupled when screwed together. Unions are tightened with two spanners, until the 2 seals, male and female, are broken.

Request for a quote

LEBRONZE ALLOYS

France

Lebronze alloys Group was born from the integration of different companies specializing in copper alloys, copper, nickel alloys, aluminium alloys, specialty steels, stainless steels, titanium and nickel superalloys. Thanks to a multidisciplinary know-how, the Group provides innovative solutions to all major industries such as Aerospace, Oil & Gas, Power, Railway but also in sectors manufacturing smaller equipment and products. Our 16 production facilities and 1,400 employees manage a unique range of metal processing technologies: continuous and semi-continuous casting, sand casting, die precision chill casting (manual, mechanized and automated), centrifugal casting, extrusion, ring rolling, hot and cold rolling, drawing, open-die forging, hot stamping, closed-die forging, cold forming, machining, non-destructive testing, etc. The Group’s commitment is to find appropriate and optimized solutions for every sector’s requirements.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of origin: China Model Number: C21000 C22000 C23000 C36000 Application: Industry construction Shape: Round Length: 1-10m Size: 1-800mm diameter Grade: brass Cu (Min): 63% Surface: Polished Standard: IS ASTM DIN EN ISO Package: Standard Seaworthy Package Delivery time:15-30 Days Supply Ability: 20 Ton/Tons per Day Packaging Details: Standard export package. Payment term:T/T,L/C etc. Port of shipment: Xiamen,China Excellent cutting, drilling performance, high strength, good electrical conductivity, strong corrosion resistance. Applicable for automatic lathe, CNC lathe processing products, such as the hardware, electrical connectors, connector etc.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Place of Origin: China Shape: as required Length: Customized Grade: Brass Cu (Min): 57%-59% Alloy Or Not: is Alloy Type: copper bar Certification: SGS MOQ: 100 kgs OEM Service: Accept Supply Ability: 50 Ton/Tons per Week Packaging Details:standard export packing Port of shipment:Xiamen,China Lead Time :15-30days Payment term: T/T,L/C etc.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

C36000, C37700, C38000, C38500, C37000

Request for a quote

KIGEMA SP. Z.O.O

Poland

Kigema applies gravity casting to produce plates and bars using all copper alloys covered by global standards: PN-EN 1982, DIN 1705, 1709, 1714, PN 91/H-87026, ASTM B271, BS 1400 and using special alloys too.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Busbars are typically used in high current, low voltage distribution and control equipment. Typical busbar applications include busway systems, low and medium voltage switchgear, transformers, earthing, electrification - lines panel boards, switchboards, and feeds to heavy electrical uses in commercial and industrial buildings - such as plating cells and feeder systems. Busbars can be made from copper or aluminum, but we couldn’ t argue the reality that copper bus bars are the better electrical conductors. Also installers can use smaller busbars if they are made by copper. On the other hand copper busbars have better resistance to corrosion than the aluminum busbars.We have large production facilities for extruded and drawn flats in various production range of sizes and shapes for electrical engineering, anodes, components etc.

Request for a quote

ARSLAN METAL SANAYI VE TICARET A.S

Turkey

Aluminium Bus Bars for power distribution give an economic advantage compared to copper bars due to the lower cost of aluminium and to a significant difference in the weight / volume.In fact aluminium bars weigh up to 70% less than copper bars, compared with a reduction in electrical capacity of only about 30%.The use of aluminium bars for carrying electrical current is therefore recommended in switchboards, distribution equipment and systems where there are no space problems, or where weight reduction is critical.Aluminium bars with different corners are available with many Thickness and many lengths.

Request for a quote

EID

France

or the service of installation technicians, eid exercises strict quality control on the copper, coils, bars, REFNET® refrigerant tubing. Here are a few explanations: THE TECHNICAL PROBLEM Technical performance of the air conditioning and refrigeration systems with the new refrigerant fluids (R410A, R32, etc.) is considerably reduced by the effect of the residual mineral oil used in the manufacture of ACR tubes ACR, used for heat exchangers and refrigerant tubing. THE SOLUTION Installing SUPERCLEAN tubes guarantees less residue inside the tubes. The internal residue ratio, defined as 0.1 mg/m, is only one sixtieth of that of conventional tubes. This means that there is no need for future cleaning of the exchangers and tubing, thus increasing the performance of the air conditioning and refrigeration systems. Our copper is manufactured using Grade A cathodes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

JINTIAN COPPER

Germany

Main products: Hpb59-1、Hpb58-2A、C3604、C3771、C37700、C36000、C46500、C46400、CZ132、CW602N、Grade A polished copper ingots Product characteristics: Excellent mechanical properties, excellent hot workability, good machinability, excellent resistance to stress corrosion. Applications: Valves, pipe fittings, water heating and sanitary ware, air conditioning components and other hardware Production capacity: 207,000 tons Honorary titles: China's Top 10 Copper Wire & Rod Company, Zhejiang Famous Brand Product, Ningbo Model Unit Manufacturing Enterprise

Request for a quote

JINTIAN COPPER

Germany

Main products: TMY copper, T2 / TU2 copper rods, profiled bars, electrical round copper billets Product characteristics: High copper content, low oxygen content, compact structure, uniformity, low electrical resistivity, high electrical conductivity, precise size, excellent mechanical properties; can be customized according to demand Applications: High and low voltage electrical appliances, power electronics, power transmission and transformation, automotive industry, molds, communication technology, cables, machining, metallurgical chemicals, construction industry Production capacity: 100,000 tons Honorary titles: Zhejiang Famous Brand Product

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We manufacture bar and tube products in our corrosion resistant Spinodal alloy, Pfinodal® (C72900), for use in downhole housings, centralizers, and joints that operate in demanding subsea environments. Advantages Our Copper nickel tin Pfinodal® (C72900) bar and tube products present a combination of unique properties that deliver significant advantages for downhole oil and gas applications. Non-sparking and non-magnetic Anti-galling Anti-corrosive Heat treatable to high hardness Safe alternative to Beryllium Copper (BeCu) Pfinodal ® (C72900) Bar and Tube C72900 copper alloy materials are available in bar and tube sizes up to 6” (152.4mm) diameters as well as in both strip and plate products. Our C72900 material is generally provided as machining bar in the aged condition with many sizes available to ship from inventory. We also offer the ability to provide turnkey solutions by providing fully machined parts to OEM drawings.

Request for a quote

RITTAL

Belgium

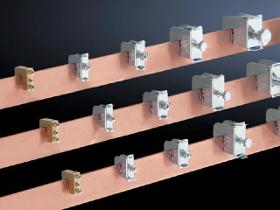

For connecting round conductors and laminated copper bars SV Conductor connection clamp, 1-4 mm², for bar thickness 5 mm

Request for a quote

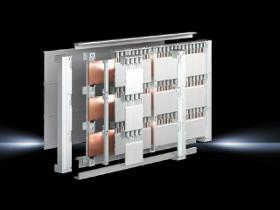

RITTAL

Belgium

For flat copper bars 40/60/80/100/120 x 10 mm SV Busbar support, 3-pole, 185 mm bar centre distance, for busbar WH: 40x10/60-120x10 mm

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc provides plug-and-play longitudinal seam welding machine for tubes, cylinders, vacuum components, water tanks, cones, flat sheets, etc. Advantages 1. Servo motor drive carriage and double linear guide way provides great precision of 0.05mm accuracy (0.002”). Motion speed reach to 2-16,000mm/min (1~640ipm). 2. Mandrel adopts with our special design copper backing-bar and copper clamper to dissipate heat quickly. 3.Strong machine structure provides large working capacity from thickness 0.1 to 10mm 4. Smart control box, you can get started quicker than you think with it. 5. High accuracy motion for laser welding standard. Welding process: All weldable metals by TIG, MIG, Plasma, Submerged arc welding and laser welding. *CE conformity.

Request for a quote

ELECTRONICON KONDENSATOREN GMBH

Germany

E57 are designed to fit directly to the terminals of your IGBT. Our range comprises standard as well as custom-tailored solutions which can be adapted to the specific geometrical and electrical requirements of your application environment. Connection is made through low-inductance copper bars which may vary in number, size and position according to your specifications. The UL:V0 plastic case houses compact and stable cylindrical windings, connected in parallel for maximum current strength and lowest possible selfinductance; it is filled with polyurethane resin, covered by a layer of UL94:V0 compliant resin protecting the winding package from humidity. Our highly reliable SecuMet™ film guarantees secure self-healing properties even under the most demanding operating conditions. Some of our E57 capacitors can be operated at ambient temperatures up to 105°C and are therefore suitable for usage in automotive and other critical applications

Request for a quoteResults for

Copper bars - Import exportNumber of results

27 ProductsCountries

Company type

Category

- Copper and copper alloys (15)

- Electrical & Electronic Components (3)

- Foundries - copper, bronze and brass (3)

- Brass (1)

- Passive electronic components and printed circuits (1)

- Pipes and tubes, copper (1)

- Railway stock and equipment (1)

- Steel & Metals (1)

- Welding, electric - equipment and supplies (1)