- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- crushers

Results for

Crushers - Import export

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

The pictures attached which the parts we supply to our customers are for your reference, they are to show our capabilities, we quote and produce the parts as per customers' drawing or samples. Concern the protection of customers' intellectual property, we do not sell any parts to the third party.

Request for a quote

KUZEY GLOBAL

Turkey

KUZEY granulators are designed according to Thermoforming production lines. Irregular draw speed of the thermoformed sheet skeleton is adapted accordingly to Kuzey Granulator . Our Crusher works in-line or off-line in synchronization with all our thermoforming and extrusion lines for continious Production as a result of standard size of Final Flake products.

Request for a quote

MPN - MECÂNICA DE PRECISÃO DO NORTE, LDA.

Portugal

Turning of all types of parts for screens and crushers, from 0 mm to 5000 mm diam, such as crankshafts, shafts and the like.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

A Primary Impact Crusher is a heavy-duty machine designed to crush large and tough materials into smaller sizes for further processing or use. It operates by utilizing high-speed impact forces generated by a rotating rotor fitted with blow bars or hammers. As the material is fed into the crusher, it is violently struck by the rapidly rotating rotor and impact tools, causing it to break apart into smaller pieces. The primary impact crusher is typically used in applications where large feed sizes and high reduction ratios are required, such as in mining, quarrying, and recycling operations. Its robust construction and powerful impact forces make it suitable for processing various materials, ranging from hard rock to recycled concrete and asphalt. The main purpose of a Primary Impact Crusher is to provide initial size reduction of material, producing a consistent and high-quality product.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

One kind of heavy-duty crushing machinery that uses impact force to reduce material size is the Horizontal Shaft Impactor (HSI) Primary Impact Crusher. The material is shattered by the impact force and the high-speed collisions against the plates or other particles in an HSI crusher which uses a rotating horizontal shaft to propel material towards fixed breaker plates as opposed to jaw crushers which compress the material between two plates. For many aggregate applications a high-quality cubical-shaped product is what this crushing method excels at producing. The HSI crusher is a great option for primary crushing operations where large materials need to be broken down efficiently because of its design which enables it to handle larger feed sizes. Because of its adaptability and capacity to produce a variety of particle sizes with good shape the HSI Primary Impact Crusher finds extensive application in the recycling and construction sectors as well as in mineral processing operations.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

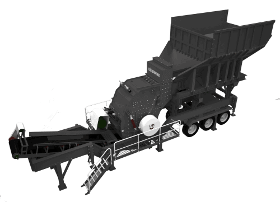

Mobile track plants are the best thing that ever happened to make your construction easy. Polygonmach sells them everywhere, and everybody says that they are good. If you need to crush some rocks or do some screening, then just go ahead and get yourself one of these. It moves around on tracks, making it better compared to other trackless plants. It can be used for any sort of work, so you can just place it anywhere you need it to work. Why should you buy a mobile track plant? Well, because it's something everybody needs. It makes construction people get things done quicker, and you won't need to think about how that works. It simply works because it's supposed to. The mobile track plants are for any kind of job. You don't need even to think about it. Just buy one from Polygonmach, and you'll see how everything gets done.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

For a variety of uses such as quarry mining and construction mobile crushing and screening plants are advanced machinery systems designed to crush and screen rocks minerals and other materials. These plants combine screening and crushing operations onto a single mobile platform providing great efficiency and flexibility. These plants are a popular option for many industrial operations because they save space and money by doing away with the need for separate crushing and screening units.In order to reduce big chunks of stone and other materials into smaller more manageable sizes for a range of applications mobile crushing and screening plants work by coordinating a series of coordinated actions. First materials like stones are fed into the feeder which controls the flow of materials to the crusher so that the stream is steady and easy to handle.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

150-250 tph Riverstone Crushing and Screening Plants are advanced facilities designed to efficiently process Riverstones into high-quality aggregates at a throughput capacity ranging from 150 to 250 tons per hour. These plants are equipped with specialized primary crushing equipment, screening machinery, and conveyors tailored for the effective processing of Riverstones into various sizes of aggregates suitable for a wide range of construction, landscaping, and industrial applications. The primary crushers, such as jaw crushers or impact crushers, are instrumental in breaking down the raw Riverstones into smaller fragments at the beginning of the processing cycle. This primary crushing stage ensures the material is prepared for subsequent processing stages. Following primary crushing, the material undergoes screening using vibrating screens to classify the aggregates into different fractions based on size.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial Size Reduction Experience seamless material processing with Lumpmaster, the ultimate low-speed, high-torque lump breaker. Clumping prevention begins when material enters the LumpMaster through the opening in the top. Pieces of material too large to pass through the rotating shaft pins and the stationary combing bars are crushed as the shaft weldments rotate. The material continues to be crushed until it is small enough to pass through. Designed for compact, inline installation in various industrial environments, our durable Lumpmaster unit ensures uniform size reduction. Choose from 12”, 18″, or 24” models in carbon or stainless steel for your specific application.

Request for a quote

POLYGONMACH MAKINE SANAYI VE TICARET LTD STI

Turkey

The 500-750 TPH Basalt Crushing Screening Plant is an industrial installation designed for processing big rocks made of basalt into varied dimensions of basalt aggregates within a range of 500/750 tonnes each hour. Basalt is a pretty dense volcanic rock, durable, and strong, which is why it is at the top of the list of items used in construction works that require strenuous and long-lived materials. These plants are highly equipped with superior machinery and equipment required to effectively and more efficiently process huge loads of basalt, which is reduced to smaller sizes that mainly make up the need for various construction and industrial applications. The processed basalt aggregates are applied to a wide range of projects, including those for road construction, infrastructure development, and the production of concrete and asphalt products.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

During metal scrap processing, conveyance systems using augers or steel belts frequently fail to consistently move bushy bundles of metal scrap because the augers and steel belts are unable to grab hold of the stringy wads. This limitation causes the bundles to bounce around the in-feed hopper until an operator manually breaks them up, or forces the bundle up the conveyor. This practice is both inefficient and unsafe. The PRAB Bundle Breaker installs in a conveyor’s in-feed hopper, where dual rotating cylinders agitate the material, tearing stringy wads of chips, turnings, and bundles apart to allow for effective processing in downstream equipment. The PRAB Bundle Breaker may be added to an existing conveyor or incorporated into a new PRAB metal scrap processing system.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce low volume turnings to flowable chips- at the source. Continuous low volume metal scrap reduction at the source. Metal crushers are the economical solution for processing stringy and bulky turnings into flowable chips. This piece can be integrated into existing equipment or free-standing. PRAB’s automated scrap removal systems are designed for volume reduction of metal turnings. The comprehensive focus on chip processing provides metalworking companies with an automated, safe and cost-effective way to process all kinds of metal scrap. The first step in this operation is to create flowable chips from metal turnings with scrap handling equipment. The Horizontal Axis Crusher processes low volumes of stringy and bulky metal turnings. This scrap metal recycling equipment is typically mounted on a stand or heavy-duty cart which fits on the discharge of the conveyor off the machining center

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Industrial metal shredders for reducing light to moderate wads of metal turnings to flowable chips. Reduce volumes by shredding metal turnings into flowable chips for higher value in scrap metal recycling. PRAB’s industrial metal shredders are a safe and cost-effective way to process all types of steel turnings and other metalworking scrap. They use less space for storage prior to scrap metal recycling and provide safer work areas. Available as a system integrated unit for use with chip processing/scrap removal equipment or as a stand-alone unit for volume reduction at the source. The development of automated scrap removal systems begins with reducing the volume of metal turnings. Milling, turning, screw machining, and swiss machining operations all produce waste that varies in size, length, hardness, and configuration depending on the tool, operation, and material characteristics.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce metal turnings and bulky wads into shovel-grade chips with a vertical axis crusher. The PRAB vertical axis metal crusher provides continuous, positive feed operation for high volume scrap reduction on the plant floor. Nested wads of metal turnings take up valuable floor space, are a safety hazard and have reduced scrap metal recycling value due to added processing costs. The PRAB vertical axis crusher is one of the most effective pieces of scrap metal processing equipment for quickly and safely creating flowable, thumbnail-sized chips from wads of turnings. Turnings are fed into the crusher’s feed hopper either by self-dumping hoppers, a plant-wide conveyor system, or an automated dump system with standard barrels or chip carts. The crusher’s feed hopper housing -with fixed cast cutters and rotating cutter- then directs the material down into the fixed and rotating cutter rings, where the material is reduced to flowable thumbnail sized chips.

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Process loose metal turnings into flowable chips. Scrap metal recycling system couples volume reduction with fluid separation to produce dry chips and reclaim 99% of valuable coolants and cutting oils. The ideal solution for scrap metal consisting of flowable chips and loose turnings

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Reduce volumes of large bundles and stringy turnings. This scrap metal equipment delivers dry, shovel-grade chips and reclaims up to 99% of valuable coolants and cutting oils

Request for a quote

KMC GLOBAL EUROPE SP. Z O. O.

Poland

Welded structure from steel sheets. They are mounted on the shaft in the housing two discs to which clamp hammers are attached. Crusher inside it is lined with carpet, in the lower part with grates, and a gap between them allows the crushed material to move downwards at an appropriate level granulation. The hammers, grate and carpets are made of material abrasion resistant. The hammers on the discs are mounted oscillatingly.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK brand SMK Series Secondary Impact Crushers can crush medium and high hardness materials such as limestone, dolomite, granite and basalt to the size of asphalt and concrete aggregate. Large size material from the primary crusher can be fed directly. High reduction rate is provided. It is the most preferred secondary crusher type in crushing and screening plants since the initial investment and operating costs are lower than other crusher types. According to the design of the facility, they can be manufactured as mobile, with fixed steel feet, with fixed concrete feet, with fixed skid chassis, pre-screened or pre-fed.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

UĞURMAK UTK Series Tertiary Impact Crushers are preferred at crushing for medium and low hardness, mostly at tertiary level and can be used as secondary crushers depending on the hardness and feeding size. It produces very fine aggregate which is required for asphalt and concrete production. The rotor can rotate in both directions. The direction of rotation is bi-directional, allowing product to be received in two different gradations without setting changes. In addition, it provides longer life since there will be bi-directional wear on rotor hammers. According to the design of the facility, they can be manufactured as mobile, with fixed steel legs, with fixed concrete legs, with fixed skid chassis.

Request for a quote

UGUR MAKINA CRUSHING & SCREENING

Turkey

The most preferred reason for UĞURMAK brand mobile wheel crushing units is the ease of assembly and disassembly. Temporary furnaces established in project works such as dams, road construction may need to be moved to a different site at the end of the project. In such cases, because they offer ease of transportation, they significantly reduce transportation costs.

Request for a quote

ECSMT MACHINERY EQUIPMENTS

Turkey

ECMT RUROMIX EMJ107 Crawler Mobile Jaw Crusher Station Strong and stable, Best quality, Long service life and low operating cost, Effectiveness and efficiency.

Request for a quote

ECSMT MACHINERY EQUIPMENTS

Turkey

ECMT RUROMIX EM130 CRAWLER MOBILE COUNTERATTACK CRUSHER STATION Strong and stable, Best quality, Long service life and low operating cost, Effectiveness and efficiency.

Request for a quote

PI MAKINA

Turkey

Cone crushers are designed to crush hard and a corrosive brook and quarry materials such as granite, basalt, and andesite. It is used as a secondary and tertiary crusher. The maximum input size is 135-215 mm. The principle of operation of cone crushers is to crush the materials with the effect of compression, cutting and bending. It offers low dust and wear-out rates as they crush the material through compression. Thanks to the long-lasting wearing parts, the crushing process lasts longer. By virtue of its advanced crusher chamber design, it provides high productivity with less wear on parts. The adjustable crusher chamber makes it possible to receive material of the desired size. In addition, operating costs are low as maintenance and repair operations can be easily carried out on the crusher.

Request for a quote

CM SRL

Italy

CR 600 mini jaw crusher, 600x300 mm mouth width complete with conveyor belt kit. With 12 Months warranty, use and maintenance manual, CE certificate.

Request for a quote

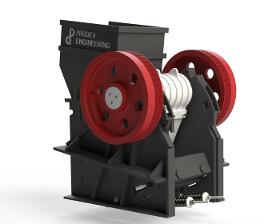

PRODEV ENGINEERING

Turkey

Can crush any hardness material. Thanks to the mechanism of the jaw crusher that high amount of mechanical pressure created by two jaws, one of which is fixed and the other making an elliptical movement, it can easily crush large stones of any hardness. Thanks to this feature, it is the most preferred crusher type in crushing and screening plants. Elliptical movement is provided by the eccentricity of the shaft to which the movable jaw is attached. This elliptical flow movement created allows the material to be fragmented between the fixed jaw and the movable jaw. High Performance Thanks to the design of the crushing chamber in jaw crushers, even in mines with high abrasiveness, less wear occurs compared to impact crushers. In this way, jaw crushers offer long-lasting working performance. Jaw crushers allow processing of larger material than impact crushers. It also works with high capacity at low motor powers. This ensures high working efficiency.

Request for a quote

GELEN MAKINA A.S

Turkey

SDK SERIES IMPACT CRUSHERS ARE USED IN THE SECOND STAGE CRUSHING OF THE SOFT TO MEDIUM-HARD QUARRY MINERALS. WITH ABILITY TO PROCESS A WIDE RANGE OF MATERIALS THEY OFFER A HIGH DEGREE OF CRUSHING IN ONE STEP WITH AN EXCELLENT PRODUCT GRADING AND INCREASED QUALITY.

GELEN MAKINA A.S

Turkey

CK SERIES JAW CRUSHERS ARE YOUR RELIABLE PARTNER IN THE TOUGHEST FEED CONDITIONS. WITH A WIDE RANGE OF SIZE SELECTION GELEN JAW CRUSHERS OFFER YOU THE MOST PRODUCTIVE AND COST-EFFICIENT SOLUTION FOR YOUR PRIMARY AND SECONDARY APPLICATIONS. EASY SETTING, SAFE AND QUICK MAINTENANCE INCREASE YOUR PRODUCTION EFFICIENCY TO A MAXIMUM LEVEL.

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Jaw plate and Side plate for Jaw crusher; Mantle, Concave for Cone Crusher; Blow bar and Hammer for Impact Crusher and Hammer/Metal crusher; Roller and Ring for Raymond Mill; Roller Liner and Disc Liner for Sand making VSI Crusher, Chocky bar and Wearing button for Excavator, which is in the material of High Manganese Steel Mn13Cr2/ Mn14Cr2/Mn17Cr2/Mn18Cr2/Mn22Cr2; High Chrome White Iron Cr20/Cr22/Cr24/Cr26, and its with Mo, Ni, Re, Ceramic, Alloy, Bi-metal etc wear-resistant materials. And HUAN-TAI products support for Shanbao, SBM, Liming, Shibang, Zenith, Metso, Sandvik, Barmac, Trio, TEREX, Pegson, Powerscreen, Kleemann, MINYU, Symons, Hazemag, Cedarapids, McClosey, Keestrack, Telsmith, Russian brands and other famous brands machine. We also can produce the wearing spare parts as per customers’ own drawings

Request for a quoteResults for

Crushers - Import exportNumber of results

185 ProductsCountries

Company type

Category

- Crushing and grinding machinery (68)

- Compactors and crushers (46)

- Agriculture - Machines & Equipment (13)

- Mining and quarrying - machinery and equipment (10)

- Goods handling systems, continuous (8)

- Casting, steel (4)

- Aluminium alloys (3)

- Excavation - works (3)

- Boxes and trays, storage (2)

- Building materials, manufacture - machinery and equipment (2)

- Compactors, construction industry (2)

- Concrete constructions (2)

- Flour milling - machinery and equipment (2)

- Machine tools - metal machining (2)

- Refuse handling - machines and systems (2)

- Taps - adjustable controls (2)

- Turning - steels and metals (2)

- Washing equipment for fruits, vegetables and fish (2)

- Agriculture and forestry - machinery and equipment (1)

- Cardboard recycling (1)