- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinder mills

Results for

Cylinder mills - Import export

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

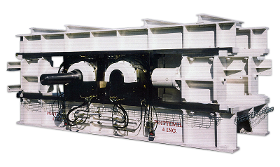

The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system (2 to 10 T/linear cm). This mill uses a patented process of pulsating pressure that reduces the level of vibration and contributes in reducing energy requirements and prolonging the service life of wearing parts. It is able to treat high production capacities (up to 500 T/h) and produce fine particle sizes (10 to 1000 microns). Cylinder mills allow for energy savings of up to 30% compared with mills that use traditional crushing methods. The cylinders are equipped with an antiabrasive coating which combined with their slow processing speed provide the grinding solution with the longest service life on the market.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Metallurgical equipment all endure heavy-duty service under very demanding environmental conditions. Equipment is subjected to moisture, dirt, saw dust, wood chips, sap and tar and slamming loads. The hydraulic cylinders used on that equipment must meet these challenges day after day. Gidrolast has over 15 decades of experience building hydraulic cylinders for this tough industry. In fact, you could say we cut our teeth in the forestry industry. For our customers, that experience is invaluable. Gidrolast designs cylinders that are able to endure the difficult conditions that metallurgical machinery encounters on a daily basis.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

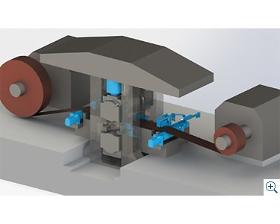

Over 130 successfully completed projects worldwide. With the combination of the understanding of the whole rolling process and the experience with modern control methods, we have implemented modernisation solutions in many rolling mills that have significantly improved the quality of the finished product and the efficiency of the production. For thickness control, for example, we convert mills from electric motor to servo-hydraulic screwdown of the stands. We also replace pancake cylinders or the combination of spindle and hydraulic screwdown with modern long-stroke cylinders. Vollmer has already modernised mills with a rolling force of 3,000 t. For the modernisation of the shape control system, too, Vollmer offers complete solutions through to the control and modification of the adjusting elements.

Request for a quote

KONYA MILL

Turkey

Its a complete ready to start 2 roller 30 ton per 24 hours project. like this project we can make any capacity flour mill factory that you need.

Request for a quote

EDILIZIA TOOLS SRL

Romania

Compatible with all joinery and optimization programs. 3 axes controlled CNC processing center can do all operations on four sides of PVC profiles such as marking, opening key holes, copy routing for water slot milling, hinge holes, handle holes etc. Milling unit opens cylinder slot with single operation. Milling unit opens handle hole with single operation. 3 axis profile gripper Automatic profile handling feature. Automatic profile length detection feature allows gripper to capture the profile without wasting time. It is possible to load profiles between 500 mm - 6500 mm to profile feeding unit. Remote desktop support Windows OS based control system with 21.5” screen. 9 high speed special design spindles. 2 saw blades Ø550 mm and Ø450 mm. Upper saw (Ø550 mm) cuts all angles between 35°-145° by servo axis control. Bottom saw (Ø450 mm) fixed at 135° for fast cutting on 45° / 135°. Fully compatible with CNC screwing machine SC200

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Cylinder mills - Import exportNumber of results

5 ProductsCompany type