- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drying tunnel

Results for

Drying tunnel - Import export

ERATEC

France

Improve existing equipment by integrating our infra-red emitters, with a positive impact on productivity, quality and energy savings. DRYING TUNNELS AND COMBI OVENS For baking, browning, toasting and marking : Biscuits, Bread, Brioche, Toast, Pizza, Pancake, Chips, Chips, Cereals, Meringues... BURNER INTEGRATION EQUIPMENT Deep fryers Kettle Coffee roasting Baking trays Decontamination of cheese crusts

Request for a quote

ERATEC

France

Choose our metal fibre burners, choose our infra-red emitter technology for a more efficient, flexible and compact installation. DRYING TUNNELS AND COMBI OVENS For baking, browning, toasting and branding : Biscuits, Bread, Brioche, Toast, Pizza, Pancake, Chips, Chips, Cereals, Meringues... BURNER INTEGRATION EQUIPMENT Deep fryers Kettle Coffee roasting Baking trays Decontamination of cheese crusts

Request for a quote

HE-JA VERPACKUNGSMASCHINEN GMBH

Germany

The company He-ja is specialized in shrink tunnel construction suitable for your product and offers a total of 40 different tunnel variants for dry as well as wet rooms. Our standard hood width is 500-1500mm wide and our standard tunnel lengths are 1,800, 2,200, 2,800 and 3,600mm. Should your product require a special solution, we will certainly find the right technical design for it. The heating power is between 15-36KW depending on the size of the hood and tunnel length. Our bestseller shrink tunnel type T600 with a total length of 1.800mm (hood length 1.200mm) and a hood height up to 300mm shrinks 80my PE shrink films without any problems with a heating power of 15KW at a capacity of up to 10 repackages/min. Thanks to the sophisticated technical design of the control components and the perfect balance between air flow and temperature, you can achieve top values in your energy balance. The actual consumption is reduced by up to 35% in production operations.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of slow-running rolling and friction bearings, rollers, transport chains or sliding surfaces on kiln trolleys, bakery machines, drying tunnels, foundry machines, boiler firing systems, plastics processing machines for welding and soldering machines etc. Advantages and benefits Highly effective due to optimum temperature-stable silicone grease formula Excellently suited for grease lubricating points subject to high-temperature loading Broad range of uses outside normal grease performance areas

Request for a quote

TASK ITALY SRL

Italy

The drying tunnel is used to remove residual water on the external surface of bottles or jars after the filling or pasteurization process. Main construction features include: - Linear stainless steel bottle conveyor belt with adjustable side guides - Structure entirely made of stainless steel, mounted on height-adjustable supports - Upper housing for high-pressure blowing turbines, in stainless steel with sound-absorbing panels - Fully openable plexiglass doors for adjustment of the blowing blades - High-pressure blowing turbines, without the use of electric resistors for low consumption * Specifically designed terminal blades to achieve adequate air force and compression * Adjustable height and inclination of the blowing blades for adaptation to different containers (bottles, jars, cans).

Request for a quote

EUROLINIA

Belarus

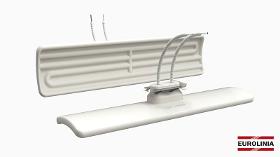

ICH-400 series infrared quartz heaters are used in industrial and commercial heating systems where instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and other infrared systems. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off. Maximun temperature 730°C. EUROLINIA quartz heating elements are hand-made using the best available components to bring you excellent performance and service life of up to 8000 hours of non-stop operation.Comply with all international standards and are interchangeable with all known brands (FQE/HQE/QQE/SQE)

Request for a quote

EUROLINIA

Belarus

ICH-400 series infrared quartz heaters are used in industrial and commercial heating systems where instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and other infrared systems. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off. Maximun temperature 730°C. EUROLINIA quartz heating elements are hand-made using the best available components to bring you excellent performance and service life of up to 8000 hours of non-stop operation.Comply with all international standards and are interchangeable with all known brands (FQE/HQE/QQE/SQE)

Request for a quote

EUROLINIA

Belarus

ICH-400 series infrared quartz heaters are used in industrial and commercial heating systems where instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and other infrared systems. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off. Maximun temperature 730°C. EUROLINIA quartz heating elements are hand-made using the best available components to bring you excellent performance and service life of up to 8000 hours of non-stop operation.Comply with all international standards and are interchangeable with all known brands (FQE/HQE/QQE/SQE)

Request for a quote

EUROLINIA

Belarus

ICH-400 series infrared quartz heaters are used in industrial and commercial heating systems where instant heat response is required: thermoforming, drying chambers, infrared tunnels and panels, heating and drying conveyors, and other infrared systems. These emitters are essential tools for the processes that need an immediate heat-up and cool down, where the product could be damaged because of a heater remaining too hot after the power is cut off. Maximun temperature 730°C. EUROLINIA quartz heating elements are hand-made using the best available components to bring you excellent performance and service life of up to 8000 hours of non-stop operation.Comply with all international standards and are interchangeable with all known brands (FQE/HQE/QQE/SQE)

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

DOLFIN INDUSTRIAL PARTS WASHING MACHINE AND SYSTEMS

Turkey

Parts are cleaned, rust removed, rinsed, phosphatized and dryed in conveyor bent tunnel w ashing machines, all these applications are nonmanuel. When the parts are moved into the machine, they exposed all these operations and moved out. These conveyor bants are 304 or 316 quality stanless steel components. Speed of the conveyor is controlled digitally. Circulation pumps are very good degisned parts. Heating system can be optianlly electric, cell cored or burneroperated. Isolation is very sensitively handled for the energy saving. PLC containing systems can be controlled from operation panel. Our all machines contain automatic water feeding and liquid level control systems.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

CONTACTLESS DRYING BY MEANS OF HOT AIRThe BF-HL belt dryer allows you to dry your workpieces using hot air. This procedure is particularly beneficial when your workpieces have the following characteristics: Sensitive parts that must not come into contact with each other Parts with tight boreholes Long and bulky parts EFFICIENT DRYING IN THE TUNNEL Your workpieces are transported through a heated drying tunnel on a fine wire mesh belt, which is also available in premium V4A stainless steel. The temperature and speed of the conveyor belt are both fully adjustable. Special equipment includes a high-pressure air knife, which blows the residual water out of the workpieces prior to drying, as well as an extension of the conveyor belt to make placing and removing the workpieces easier.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Drying tunnel - Import exportNumber of results

18 ProductsCountries

Company type