- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- extrusion blow-molding

Results for

Extrusion blow-molding - Import export

PHILPLAST LTD.

Bulgaria

Using the technologies of extrusion blow moulding we create: - Bottles and vials - Jars - Canisters with and without handles - Plastic articles with a slanted neck - Plastic articles with a transparent line for content level control The volume of blow-molded articles can vary from 10 to 2000ml. These products have numerous applications in multiple industries – technology, cosmetics, chemical, automotive, etc. We use a wide variety of plastic materials: PP, PE, PVC, ABS, PS, POM и PA, all sourced from established and reliable suppliers from Germany, Italy, Germany and Great Britain.

Request for a quote

W. MÜLLER GMBH

Germany

The extremely space-saving design of our screen changer allows a lot of creative freedom, both with new machines and in the case of retrofitting, since the structure of the extruder platform only needs to be adjusted a little. The screen changer is installed instead of a connection piece and can be equipped with a hydraulic or electric drive. The simplest way, however, is to use a cordless screwdriver, which makes changing bits a quick and easy endeavor. Screen changers are available for all common throughputs.

Request for a quote

W. MÜLLER GMBH

Germany

The perfect combination of head and complete extrusion is the heart of every blow molding machine - tailor-made for your product and adaptable to every machine. Our platforms guarantee the greatest possible security and user-friendliness for users.

Request for a quote

W. MÜLLER GMBH

Germany

Our extrusion heads for blow molding meet the highest demands in terms of precision, availability, performance and ease of use. And They ensure your safe and cost-efficient production.

Request for a quote

CONSTAB POLYOLEFIN ADDITIVES GMBH

Germany

CONSTAB offers you a wide range of masterbatches and compounds for polyethylene films, such as: — Bubble Film — Electronic packaging film — Injection molding and extrusion blow molding — Foamed films — Food packaging films — Greenhouse films — Film packaging for industry and food — Industrial films — Industrial packaging films Our masterbatches and compounds provide your products with the properties they should later have.

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

KHARKIV HIMPROM LTD

Ukraine

The new range of COEX plastic bottles BP.0025 (250 ml), BP.005 (500 ml), BP.01 (1000 ml) is resistant to chemically aggressive substances and is suitable for agrochemicals (herbicides, pesticides, insecticides, etc.), auto chemicals, household chemicals and other substances based on organic solvents. The use of high density polyethylene with the polyamide protective layer manufactured by co-extrusion blow molding COEX allows to use of the canisters for liquids which cannot be filled into polyethylene bottles due to the rapid destruction of the container or due to diffusion of products through the packaging walls. We offer you to expand the range group and core audience for your product. The bottles supply around Ukraine, Europe, CIS and Russia is conducted by the qualified transportation companies. The bottles customer pick-up is possible from Vasishchevo, Kharkov region, Ukraine or from the warehouse in Belgorod, Russia.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent for casting, injection moulding, blow moulding and extrusion processes of plastics and elastomers Prevents sticking, for example of excess adhesive and sealant Eliminates creaking and squeaking noises when surfaces made of plastics, elastomers and metals rub on each other For easy fitting of plastic and rubber profiles, e.g. in door and window construction Lubricant for cutting edges of paper, cardboard, veneer or textile machines, etc. Advantages and benefits NSF H1 registered Highly effective due to outstanding surface wetting and formation of separating film with antistatic properties Broad range of uses for long-term lubrication, protection, care and impregnation of material surfaces made of metal, plastic and rubber Minimal consumption through formation of extremely thin films Resistant to water and weathering Long spray tube for precision application MOSH/MOAH-free

Request for a quote

MIKROPOR

Turkey

Water Process Chiller is designed to meet the needs of many applications that require stable working conditions with maximum quality and cleanliness of the cold process fluid. Proses Çillerleri_Ana Görsel-min Our brand-new compact, robust and reliable MCHILL Series Water Process Chiller is designed for industrial applications and manufactured with the highest quality and safety standards. MCHILL is not only extremely compact and easy to use but also ensures an accurate control of water temperature. MCHILL Series is used for Food & Beverage Industries, Wineries, Dairies, Breweries, Bottling, Storage, Plastic Industries-Injection, Extrusion, Blow Molding, thermoforming, Laser Industry-Cutting, Welding, Profiling, Optics, Medical; Chemical & Pharmaceutical Industry-Natural Gas, Jacketed Vessels, Polyurethane, Laboratories, Healthcare, Petrochemical, Temperature Control; Engineering Industry-Machine

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using extrusion blow moulding with the following characteristics: Volume: from 10 to 2000ml.; Materials: PP, PE, PVC, ABS, PS, POM, PA and others; Specialty bottles: bottles with a slanted neck, with a transparent line for content level control, high pressure resistant bottles and others; Industries: technology, cosmetics, chemical, automotive and others. We also offer a complete set of services that help in the manufacturing of plastic products and mould maintenance: Design, 3D model and a “Rapid Prototype”; Tooling; Mold servicing and repairs; Additional processing and assembly of plastic articles.

Request for a quote

PHILPLAST LTD.

Bulgaria

Our tooling engineers and designers have extensive experience in creating various blow moulds and injection moulds with the following characteristics: Extrusion blow moulds with volume of the articles up to 20 litres; Injection moulds with a maximum size of 546 mm X 896 mm and a maximum weight of 2,500 kg. We also offer a complete set of services that help in the manufacturing maintenance of mould tools: Design, 3D model and a “Rapid Prototype”; Servicing and repairs.

Request for a quote

FATRA A.S.

Czech Rep.

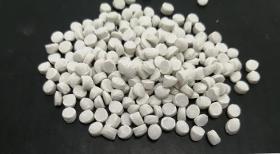

Regranulate One of the reasons for using secondary raw materials (plastic waste) is their economic advantage caused by reduced material exigency and generally lower prices of inputs – recycled products/re-granulates. Using the higher amount of recycled product in products as an alternative to primary resources usually leads to their lower final price, which contributes to better competitiveness of products on the market. We produce re-granulates for injection moulding, blow moulding, and extrusion on modern re-granulating lines. Based on customers’ requirements, we can produce re-granulates with required melt flow index, of various colours, including re-granulates with filling compound content. In the production, we process internal and external waste. Product advantages continuous quality of inputs – secondary raw materials directly from the production stable production process with continuous control optional re-granulate colouring, or adding additives directly in the...

Request for a quote

SB-TRADING (BVBA)_M

Belgium

HDPE Blue Drum Scrap Commodity: HDPE Blue Drum Scrap Quality: Cold Washed / Hot Washed Color: 100% Blue Color Post-industrial grade and consumer mix Packing: Pressed in bales, Commodity: HDPE Blue Drum Scrap Regrind Grade: Extrusion – Blow Moulding Quality: Cold Washed / Hot Washed Color : 100% Blue Color Flake Size: 4-10 mm Moisture: less than 3% Post-consumer grade Packing: In Jumbo big bags HDPE Regrind Flakes from Milk Bottles Density: .950 – .960 g/cm^3 Melt Flow: .40 – .95 g/10 min. This is HDPE REGRIND CLEAR NATURAL. HDPE Regrind from milk bottles is 100% Natural without caps and labels. 100% HDPE Bottle, blow grade MFI less than 1%. HDPE Regrind size: 10 cm to 15 cm

Request for a quote

HEXPOL TPE GMBH

Germany

Thermoplastic Vulcanisate or TPV compounds are high performance materials designed for demanding and dynamic applications. They are composed of a highly vulcanised rubber phase dispersed throughout a thermoplastic matrix and combine the processing ease, efficiency and recyclability of a thermoplastic with the improved flexibility, low compression set and resistance to aggressive fluids of a vulcanised rubber. This combination makes TPV’s ideal for variety of applications in several markets such as automotive, construction and appliances. Our Dryflex V range offers: A wide range of hardness’ Grades that can be processed by injection moulding, extrusion, blow moulding and thermoforming Service temperatures of -60°C to 135°C Improved resistance to aggressive fluids such as oils, acids, bases and aqueous solutions Low compression set Low flex fatigue Lightweight parts Design flexibility Recyclability Excellent weathering and environmental resistance Download Dryflex V - Thermoplastic

Request for a quote

TRADEGE FOREIGN TRADE AND CONSULTING

Turkey

Calcium carbonate filler masterbatches is the most effective cost-saving solution for worldwide plastic processors. CaCO3 filler masterbatch not only cuts down plastic production costs by replacing a part of virgin polymer during extrusion, injection and blow molding, but also increases output, improves production conditions as well as a number of physical and chemical properties of finished plastic products. Fillers are recommended for applications in Raffia & FIBC, Lamination, Blown Film, Injection & Blow Molding. Performance Characteristics: •Excellent Anti-Fibrillation. •Reduces Cost. •Enhance Anti-Slip property. •Improves Stiffness.

Request for a quote

MOTAN-COLORTRONIC GMBH

Germany

GRAVICOLOR doses and mixes up to six materials precisely and with maximum recipe accuracy. These modular gravimetric units are designed for injection, blow moulding and extrusion and provide throughputs up to 2200 kg/h. Independent of recipes, materials, or the operational environment, IntelliBlend analyses all process data achieving the best possible operating point at any time through continuous self-optimisation. Recipe integrity results in excellent and consistent product quality. The GRAVICOLOR series is part of the motan range of products and systems for all stages of management, conditioning and preparation of plastic granules. The design quality, plus the engineering, ensures high performance and reliable operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MATTES KG

Austria

HDPE Blue Drum Scrap Commodity HDPE Blue Drum Scrap Quality Cold Washed / Hot Washed Color 100% Blue Color Post industrial grade and consumer mix Packing Pressed in bales, Commodity HDPE Blue Drum Scrap Regrind Grade Extrusion – Blow Moulding Quality Cold Washed / Hot Washed Color 100% Blue Color Flake Size 410 mm Moisture less than 3% Post consumer grade Packing In Jumbo big bags HDPE Regrind Flakes from Milk Bottles Density .950 – .960 g/cm^3 Melt Flow .40 – .95 g/10 min. This is HDPE REGRIND CLEAR NATURAL. HDPE Regrind from milk bottles 100% Natural without caps and labels. 100% HDPE Bottle, blow grade MFI less than 1%. HDPE Regrind size 10 cm to 15 cm

SUZHOU BESTAR BLOW MOLDING MACHINERY CO.,LTD

China

Main Features Of 25 Liter Lubricate Oil Blow Molding Machine(In Mould Labeling System): Bestar extrusion blow molding machinery company is specialized in producing high-speed,high-efficient multi-layer,multi-cavities 25 liter lubricate oil blow molding machine. Bestar Extrusion Blow Molding Machine is for the purpose of use single station and double station producing bottles,jerry cans,stacking barrels.from 50ml up to 30liters. The industries scope are Daily chemical,laundry detergent, lubricant, pharmaceutical pesticide, chemical stacking barrels, shaped engineering etc. and it is capable to be configurated with multiple die heads,multi layer especially suitable for massive production bottle with mutli layer such as EVOH,Nylon and up to 6 layers.

Request for a quote

SUZHOU BESTAR BLOW MOLDING MACHINERY CO.,LTD

China

Bestar blow moulding machinery company is specialized in producing high-speed,high-efficient multi layer multi cavitites extrusion blow moulding machine. We offered our machines and services to famous Unilever,Heinz Group, Reckitt Benckiser,BASF,Syngenta,Bayer,SK,TOTAL,SHELL and so on. Also Our Laundry Detergent Bottle Blow Moulding Machines has sold all around the world and region. Main Features Of Laundry Detergent Bottle Blow Moulding Machine: The Bestar laundry detergent bottle blowing moulding machine module is the core components of plastic molting part which adopts the German technology.Different models type is available according to customers’ requirements,such as E60/25, E70/25, E80/25 etc.The extruders has improved output with grooved feed section and forced cooling method;Barrel with ceramic heating ring with strong fan for cooling,thus ensuring the effective control of the temperature of each segment;The hardened gear box ensures long service life;the entire extrusion...

Request for a quote

SUZHOU BESTAR BLOW MOLDING MACHINERY CO.,LTD

China

Jerry Can Blow Molding Machine B20D-750 (2 Stations 2 Cavities): Bestar plastic blow moulding machinery company is specialized in producing high-speed,high-efficient multi layer multi cavitites extrusion blow moulding machine. The development of Plastic Bottle Blow Moulding Machine is for the purpose of producing from 50ml to 30liter the industries scope are Daily chemical,laundry detergent, lubricant, pharmaceutical pesticide, chemical stacking barrels, shaped engineering etc. and it is capable to be configurated with multiple die heads,multi layer especially suitable for massive production bottle with mutli layer such as EVOH,Nylon and up to 6 layers. This sauce plastic bottle blow moulding machine can provide you with food and beverage packaging bottle blow molding machine.Series blow moulding machine can blow moulding: milk bottles,yogurt bottle, juice bottles,edible oil bottle,soy sauce pot,oil pot,motor oil bottle and engine oil bottles etc. The Bestar P lastic Bottle Blow...

Request for a quote

SUZHOU BESTAR BLOW MOLDING MACHINERY CO.,LTD

China

Main Features Of Plastic Bottle Blow Moulding Machines: Bestar plastic blow moulding machinery company is specialized in producing high-speed,high-efficient multi layer multi cavitites extrusion blow moulding machine. The development of Plastic Bottle Blow Moulding Machine is for the purpose of producing from 50ml to 30liter the industries scope are Daily chemical,laundry detergent, lubricant, pharmaceutical pesticide, chemical stacking barrels, shaped engineering etc. and it is capable to be configurated with multiple die heads,multi layer especially suitable for massive production bottle with mutli layer such as EVOH,Nylon and up to 6 layers. This sauce plastic bottle blow moulding machine can provide you with food and beverage packaging bottle blow molding machine.Series blow moulding machine can blow moulding: milk bottles,yogurt bottle, juice bottles,edible oil bottle,soy sauce pot,oil pot,motor oil bottle and engine oil bottles etc. The Bestar P lastic Bottle Blow Moulding...

Request for a quote

SUZHOU BESTAR BLOW MOLDING MACHINERY CO.,LTD

China

Main Features Of Extrusion Blow Molding Machine: Bestar extrusion blow molding machinery company is specialized in producing high-speed,high-efficient multi layer multi cavitites extrusion blow molding machine. The development of Extrusion Blow Molding Machine is for the purpose of producing from 50ml to 30liter the industries scope are Daily chemical,laundry detergent, lubricant, pharmaceutical pesticide, chemical stacking barrels, shaped engineering etc. and it is capable to be configurated with multiple die heads,multi layer especially suitable for massive production bottle with mutli layer such as EVOH,Nylon and up to 6 layers. This sauce extrusion blow molding machine can provide you with food and beverage packaging bottle blow molding machine.Series blow molding machine can blow moulding:milk bottles,yogurt bottle, juice bottles,edible oil bottle,soy sauce pot,oil pot,motor oil bottle and engine oil bottles etc. The development of automatic extrusion blow molding machine...

Request for a quote

GDI CORPORATION

Bulgaria

This leading technology allows for the highest quality manufacturing of bottles/containers of various sizes and materials such as PP, PE, PET, and others upon request. We use market-leading production machines.

Request for a quote

PET TECHNOLOGIES

Austria

Automatic stretch blow molding machine APF - 6004 to produce PET bottles. Output - 6000 bph. Bottle volume - 0.2 - 2.0 L

Request for a quote

CYPET TECHNOLOGIES

Cyprus

CYPET single stage injection stretch blow molding machines automatically produce finished blown containers directly from PET resin. The system utilizes CYPET’s patented technology that uses only two stations, one for injection molding the PET preforms, and the second to stretch blow mold the PET containers. The machines have unparalleled flexibility, allowing production of containers ranging from 20ml up to 120Ltr, with up to 400 mm neck diameter. Highly optimized, energy-saving servo-hydraulic technology as well as the use of an air recovery system as standard, reduces energy consumption by up to 40% (0.31kWh/kg of finished bottles). The machine’s generous clamping force and platen size, allows molds with higher cavities achieving higher output with less investment compared to conventional technologies. The machine can mold PET water bottles, jerrycans, liquor miniatures, wide mouth jars, large drums, pressurized containers. Handles can be incorporated as one piece with the bottle.

Request for a quote

PET TECHNOLOGIES

Austria

Equipment type: semi-automaic Bottle Volume, l: 0,2 - 2, 2 - 3, 3 - 6 Output, bph: up to 800 bph Your product: Water and CSD, Beer, Milk and dairy products, Oil and vinegar, Household & automotive Technical data Neck diameter28-80 mm Low pressure10 bar Blowing pressure15 (up to 25) bar Low and high pressure air demand0,8m³/min for bottle 1.5 l Cooling liquid temperature 7-9 °С Voltage supply400 V / 50 Hz Installed power 8 kW Overall dimensions1600 х 600 х 2200mm 1200 х 600 х 1100mm Weight ~ 500 + 220 kg

Request for a quoteResults for

Extrusion blow-molding - Import exportNumber of results

28 ProductsCountries

Category

- Blow moulding of rubber and plastic (8)

- Bottles and jars, plastic (3)

- Electric motors and parts (3)

- Plastics - machines and material for industry (2)

- Scrap iron - salvaging and recycling (2)

- Filtering equipment and supplies (1)

- Granules for plastics (1)

- Plastics - packaging (1)

- Plastics moulding (1)

- Silicones (1)