- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flat gasket

Results for

Flat gasket - Import export

CINCHSEAL EUROPE GMBH

Germany

We manufacture ready-to-install standard and special flat gaskets in large and small series. Depending on the area of application, different materials are used. Flat gaskets are mostly static and are mainly installed between two flanges in apparatus and pipeline construction. Depending on the quantity and size, the most economical manufacturing process is used.

Request for a quote

DEME

France

Flat gasket for gas from DN12 to DN50 In synthetic-Rubber Fibre in conformity with NF E29-533 standard In Nitrile (NBR) 85 +/- DIDC in conformity with EN549 A2 H3 standard

Request for a quote

REP INTERNATIONAL

France

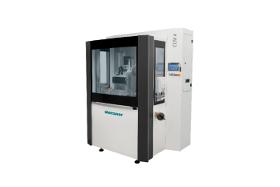

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

In short, large flat gasket REP machines mean Clamping quality Thick traverses, multiple synchronized clamping operations; Injection of long thin sections Injection pressure up to 3,000 bar and circuit division with several injection units; Productivity Very fast 3step clamping, doubleplate kits; Ergonomics/access to the mold Widthwise heating plates, demolding kit or sliding platen. These types of machines have been developed for largeseries injection molding involving parts with inserts, for example the injection molding of battery pack seals. Based on its longstanding experience in this field, REP offers a comprehensive range of machines with largesized heating plates and adjustable configurations to fully comply with the technical specifications of each application and all client’s needs.

Request for a quote

REP INTERNATIONAL

France

Machine features Closing force 5,000 kN. Size of the platens 1,500 x 630 mm. Injection volume 740 cm³. Machine developed for the largeseries molding of parts with inserts, such as for example the injection molding of housing seals.

Request for a quote

REP INTERNATIONAL

France

Type V410 Extended 1,600kN Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

REP INTERNATIONAL

France

V410 LSR Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed the mandrel cutting machines of the SR series for cutting off sealing rings from injection-moulded or extruded tubes with different diameters. These machines are characterised by their unique processing method and high cutting quality. First, pre-extended "rubber tubes" are clamped onto mandrels. Due to the special design of the mandrels, the mandrel can be set up and removed quickly and without special previous knowledge. The mandrels are then automatically clamped in the machine between rotating spindles and production is started. A knife carriage travels along the tubes and cuts the flat sealing rings to the desired length with either push-fit or circular knives, depending on the requirements. This cutting method is particularly impressive with its high cutting quality in combination with a high output.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

The special feature of the Metzner CCM 4: the circular cutting machine handles both wet and dry cutting. Depending on the type of cut, the CCM 4 is equipped with a water-cooling lubrication system or micro-knife moistening and preparation for suction. The standard model comes with an integrated discharge conveyor (800 mm length); application range both in-line and off-line. For tubes with suitable material properties the CCM 4 Gasket offers the possibility to cut flat gaskets with the circular knife. Suitable for tubes with max. 30 or 50 mm diameter and a tube length of 1 mm to 1000 m.

Request for a quote

URM - UNIVERSAL RUBBER MANUFACTURING NV

Belgium

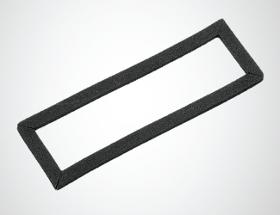

Cellular rubber is expanded black rubber material with closed cells. Cellular rubber has a lower permanent deformation value than polyethylene foam Available in densities from 90 450 kg/m³. doneAvailable in blocks up to 60 mm thick, depending on the type doneAvailable in rolls with adhesive. More information Cellular rubber are used for static sealing , shock absorbtion, and dampening material in all types of industry earth moving equipment, automotive industry, cab trimming, ventilation, building industry, etc.. Gaskets and flat sealings are produced through die cutting (for high volumes), or by waterjet cutting (for lower volumes and prototyping) Industry use oil and fuel resistance, chemical resistance, temperature resistance, flammability , weather resistance, compression set, compression deflection

METZNER MASCHINENBAU GMBH

Germany

The tubing specialist with unique precision and working speed for very thin, tension-elastic and pressure-sensitive materials. KL-BV is available in the equipment line Green and as KL-BV Gasket. The Metzner KL-BV cutting machine stands out for its precision, compact design, and the wide range of processing options such as silicone tubes, flexible profiles and gaskets. KL-BV GASKET With its particularly thin blades and precision feed, the KL-BV Gasket is ideal for cutting flat gaskets with a diameter of up to 12 mm.

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and strong parts or structural elements that can be used at temperatures up to 1 .600 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% natural — biosoluble — high thermal shock resistance — low thermal conductivity — high chemical resistance * — recyclable — low weight — good tear resistance — high flexibility — easy processing — harmless to health — complicated geometries can be produced * A special coating is required to achieve high acid resistance. Available from manufacturer. Fields of application: gaskets, crucibles, thermocouple housings, coupling devices in continuous casting plants, expansion joints, convex and flat gaskets in blast furnaces, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

highquality, microfibre paper with spacers of thermoplastic adhesives Vshaped construction particletight frame compound MDF or galvanised sheetsteel frame flat profile gasket very large filter surface area through Vshaped construction selfsupporting media pack with optimised pleating geometry mounting independent of position enables easy installation

Request for a quote

KALTHOFF LUFTFILTER UND FILTERMEDIEN GMBH

Germany

highquality microfibre paper with spacers of thermoplastic adhesives particletight frame compound MDFframe, anodised aluminium profile or galvanised sheetsteel frame flat profile gasket selfsupporting media pack with optimised pleating geometry mounting independent of position enables easy installation

Request for a quote

VILLINA LLC

Russia

We supply rubber sealing O-ring comforming with GOST 9833-73 “Rubber sealing O-rings”. We produce: flat paronite and fluoroplastic gaskets in accordance with GOST 481-80 high-temperature TEG (thermally expanded graphite) gaskets according to STO 00220575.001-2007 heat-resistant spiral-wound gaskets according to GOST R 52376-2015

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KEMTRON LTD

United Kingdom

Electrically conductive elastomers are made from silicone or fluorosilicone loaded with highly conductive particles such as silver plated aluminium, silver plated copper, nickel coated graphite and pure nickel. Available as extruded profiles, “O” rings, moulded components, and flat sheet for die cut gaskets. Conductive elastomers offer an excellent temperature range and are resistance to compression set and Fluorosilicone has superior resistance to fuel oils and solvents.

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

They include a broad range of connection systems for bridge segments, gaskets, guidance rods, adhesives, packers, lifting-injection and grounding systems. FIP INDUSTRIALE can design, develop, test and supply any accessory for bridge segments, in every case in which tunnels are mechanically excavated by means of TBM mills which results in the use of prefabricated bridge segments. It can also supply flat jacks, bentonite or vulcanized rubber hydroexpansive gaskets for any type of tunnels and other structures which do not imply TBM mills TYPES: Watertight gaskets Adhesives Load spreading pads Inserts Biblock systems and bolts Guidance rods Flat jacks Hydroexpansive gaskets

Request for a quoteResults for

Flat gasket - Import exportNumber of results

20 Products