- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- flue gas heat exchangers

Results for

Flue gas heat exchangers - Import export

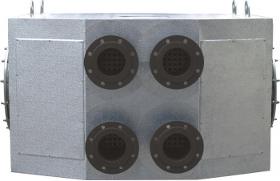

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

A flue gas heat exchanger is part of the standard equipment for energy-optimised and environmentally friendly boiler operation. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 15% when using condensing technology — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting

Request for a quote

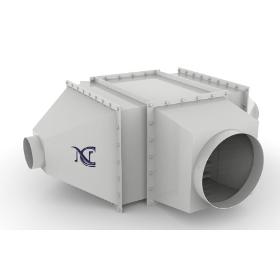

NC MANUFACTURING AND ENGINEERING

Turkey

Recuperator systems are heat exchangers that produce hot air by utilizing the energy of high-temperature waste flue gas generated in furnace systems, boiler systems and various processes. Recuperators various heating needs of facilities such as combustion air preheating and ambient heating are met and energy consumption is minimized. Compared to economizers, they have larger surface area and dimensions at the same heat capacity. They can be manufactured as finned tube and straight tube. Recuperator heat exchangers can be made from numerous materials steel, stainless steel and other special materials.

Request for a quote

ANTHERMO GMBH

Germany

Temperature exchange between a gas and a liquid In the case of air-water heat exchangers (also called gas-water heat exchangers), there is a temperature exchange between a gas (usually air) and a liquid. Finned heat exchangers can cover various areas of application: - heating and evaporating, - cooling and condensing as well as heat recovery. In this context, lamellar heat exchangers are also called air heaters or air coolers. Air-water heat exchangers are often also used as exhaust gas heat exchangers or flue gas heat exchangers in order to recover the energy from warm or hot exhaust gases. Lamella packs for a large exchange area In order to achieve the largest possible exchange surface between the air and the medium (liquid) within the heat exchanger, lamellas or lamella packs are attached to the pipe system.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

With the effective recovery of flue gas heat, you can save up to 14% on fuel and, at the same time, reduce emissions. — Effective heat recovery and reduction of flue gas losses — Maximum efficiency gain when using condensing technology — Fuel savings of up to 7%, or up to 14% when using an additional downstream condensing heat exchanger — Intelligent control for a long service life and high level of efficiency — Compactly integrated into the boiler or as a stand-alone version for simple retrofitting — Feed water cooling or combustion air preheating as alternatives to the condensing heat exchanger

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

— For continuous feed water control — Increased efficiency of flue gas heat exchangers — Fewer pump circuits — Constant boiler water level — Minimum flow rate for cooling the feed pump is assured Highly efficient boiler systems with perfectly matched boiler house components ensure that low levels of energy consumption and emissions are achieved.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BASE GROUP SP Z O.O.

Poland

Base Group specializes in the manufacturing different types of steel constructions for energy. We are manufacturer of high quality steel structures for the energy sector in accordance withall standards and legal regulations. We produce in accordance with ISO 3834-2, PN EN 15085, PN EN 1090 and ISO 9001:2015. Our knowlage and experiance has made us a provider of the word-leading company on the global market of electric power production and transmission.

Request for a quote

EUROPEM

Belgium

Most of the Europem incinerators are equipped with waste heat recovery systems. Europem has supplied a wide range of waste heat recovery installations including steam boilers, thermal oil boilers, gas-liquid heat exchangers, gas-gas heat exchangers, bath heaters and air heaters. All waste heat recovery installations are tailored to the needs of the client and the optimal design of the overall installation. Our range of waste heat recovery systems include: -Fired tube boilers with or without economizer. Single pass and multi-pass systems can be supplied Boilers can be equipped with an on-line cleaning system to allow operation with dust-loaded (flue) gases Boilers up to 30 MW capacity can be supplied with pressures ranging from 10 to 22 bar. - Single pass and multi-pass systems can be supplied -Water tube boiler boilers with or without economizer Superheated or saturated steam Horizontal or vertical boiler arrangements Bundles in refractory lined casing or with membrane walls Capacities up to 40 MWth with pressures ranging from 15 to 65 bar. – Thermal oil boilers – Bath heat exchangers – Air – flue gas tube and shell heat exchangers – Flue gas – liquid tube and shell heat exchangers – Air heaters Heat exchangers can be manufactured in carbon steel or high grade alloys e.g. Duplex, Hasteloy, Inconel, AISI 316, AISI 304.

Request for a quoteResults for

Flue gas heat exchangers - Import exportNumber of results

9 ProductsCompany type