- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- anodic coating

Results for

Anodic coating - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

The double anodization process can be used to create a protective anodization layer on various parts of a consumer electronic product, including top and bottom portions, side walls, and chamfered portions. It’s particularly useful for improving corrosion resistance and wear resistance, and it provides better adhesion for paint primers and glues than bare metal does. The process is not limited to aluminum; it can also be applied to other metals like titanium, zinc, magnesium, and others. However, aluminum is the most common due to its widespread use in consumer electronics and other applications where weight and durability are important factors.Double anodization is a complex process that requires precise control over the electrolytic solutions, electrical current, and time to ensure the desired outcome. It’s a testament to the advancements in materials engineering and its ability to tailor the properties of metals for specific applications.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

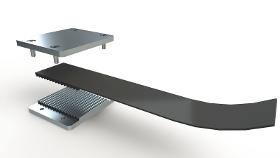

KEIPER timing belt clamping plates can be made of many different materials, e.g. aluminum, steel or stainless steel. Keiper can produce them in all pitches and designed according to your specifications and drawings. This means that you will receive the optimal solution for the intended application and load. Our timing belt clamping plates work together optimally with our extensive and complete range of timing belts: in other words, a perfectly matched system for your requirements. We also have a large number of standard aluminum clamping plates on stock, which can be reworked according to your specifications (e.g. bores and mechanical processing based on drawings). Furthermore, such special surface coatings as hard coating, anodizing, zinc coating or bronzing improve the corrosion and wear resistance.

Request for a quote

SIKO GMBH

Germany

Premium knurled aluminum handwheel. Compact design. Various sizes. Surface plastic-coated, anodized or bright-finished. Various hub versions.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing toothed shafts can be made of such diff erent materials as aluminum, steel or stainless steel. The fact that they can be produced with all pitches and designed according to your specifications and drawing ensures optimal solutions for all applications and any loads. Our synchronizing toothed shafts work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifi cations within a short time (e.g. bores and machining based on your drawings). Special surface coatings, e.g. such as hard coating, anodizing, zinc coating or bronzing, improve corrosion and wear resistance.

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

KEIPER synchronizing pulleys can be made of such different materials as aluminum, steel, stainless steel, gray cast iron or plastics. The fact that they can be produced with all pitches and designed according to your specifications and drawings ensures an optimal solution for any application. Our synchronizing pulleys work together optimally with our extensive and complete range of timing belts. Together they are a perfectly matched system for your application. We have a large range of standard pulleys on stock, which can be reworked according to your specifications. Special surface coatings, such as hard coating, anodizing, zinc coating, bronzing, improve the corrosion and wear resistance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

REA ELEKTRONIK GMBH

Germany

CO2 laser marking systems are part of the gas laser group: the laser beam is generated in an enclosed laser tube which is filled with carbon dioxide. The REA JET CL is suitable for the marking of packaging, glass, wood, plastics, PVC, anodized aluminum, the color removal on surfaces as well as direct marking of foods. In the creation of texts, graphics and characters there is complete freedom of design. Applications — Marking of glass, wood, rubber, engraving and color change marking of plastics (automotive, medicine, consumer goods) — Coding of cardboard boxes and outer packaging (e.g. in the pharmaceutical, cosmetic and food sectors) — Coated substrates (e.g. anodized aluminum) — Direct marking of foodstuffs — Laser color change marking — Color mirror engraving

Request for a quote

FATH GMBH

Germany

To fasten components to profiles, brakes the anodized coat of the profile - thus ensuring a safe, electrically conductive connection Material: — Steel — Stainless steel — Plastic PA Measures: Thread: M4 - M8 length hammer screw: 16-60 mm many different versions in lengths and widths in the delivery assortment individual designs on request extras: Rotation aid: polyamide spot coating on request surface: with dry sliding film, zinc-nickel or zinc-flake coating on request Note: Matching flange nut available

Request for a quote

MINEON HANDEL GMBH

Germany

Black Powder Coated or Anodizing Aluminum Alloy Handle,different Lengths available,with L=100mm handle,can bear a maximum static load 2500N.Easy Installation,ROHS compliance.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Hard anodizing (or hard coating) is the electrolytic oxidation of semi-finished aluminum products, which improves a surface in such a way that high demands are made in terms of wear resistance and high corrosion protection. At temperatures of 0°C, alloy-dependent layer thicknesses of up to 100 μm develop, which have a greater surface hardness than stainless steel. This ceramic-like layer is not conductive and also serves as electrical insulation. Maximum measurements 2750 x 700 x 300 mm

Request for a quote

FREILACKE EMIL FREI GMBH & CO. KG

Germany

Coating with a FreiLacke electrodeposition coating (EC) is the economical and environmentally-friendly method of protecting and embellishing metal substrates. The procedure is principally suitable for all conductive metals and alloys. The component to be coated can be connected either as a cathode (cathodic electrodeposition coating) or as an anode. Electrodeposition coating as a method of corrosion protection is used in the automotive industry as well as many other sectors. The EC method enables process recycling and can be fully automated. Ranging from heaters to switch cabinets and shelves – FreiLacke electrodeposition coatings give surfaces great mechanical strength and are ideal for customer-specific developments.

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

A combination of the anodizing process with coloring (absorption dyes and alternating current coloring) offers a wide range of design, functional and aesthetic options for creating an attractive surface (e.g. for cases, dials, front panels, jewelry, etc.). Maximum measurements 700 x 700 x 500 mm

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

The anodizing process is the creation of an oxidic protective layer through anodic oxidation in the uppermost aluminum zone. A 5 to 25 μm thin, resistant hard layer is created that protects against corrosion. — Semi-automatic anodizing plant, processing dimensions 4000 x 1000 x 500 mm — hand anodizing plant, processing dimensions 2500 x 700 x 500 mm

Request for a quote

LECHMANN ENGINEERING GMBH

Germany

Passivation is the chemical treatment of surfaces to increase corrosion protection with excellent conductivity. Positive for subsequent painting and powder coating processes, to reduce fingerprint sensitivity and to change the appearance (gloss, color). Maximum measurements 4000 x 1000 x 360 mm

Request for a quoteResults for

Anodic coating - Import exportNumber of results

14 ProductsCountries

Category

- Aluminium coatings (4)

- Conveyor belts (3)

- Turning - steels and metals (1)

- Automation - systems and equipment (1)

- Electric and electronic components - machines for manufacturing (1)

- Locks, bolts and keys (1)

- Nuts and bolts (1)

- Paints and varnishes (1)

- Tempering, metals - machinery and installations (1)