- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hydraulics systems

Results for

Hydraulics systems - Import export

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

All rollers hardened and finepolished Multiple backup rollers to prevent deflection Specially suitable for highstrength steel applications Parallel adjustment of upper roller bank with tilting via spindle type lifting devices With optional synchronized drive of pinch and work rollers Drive system via transfer gear box and universaljoint shafts with length compensation and quickrelease coupling Warpresistant stand in modular design to allow extension with catenary rollers, threading system, loop bridge or conveyors for operation as partsstraighteners etc. Hard chromed rollers Polyurethane coated rollers Hydraulic threading systems in different grades Motorized adjustment of upper roller bank with optional jobmemory Central edge guide adjustment via handwheel (optionally motorized) All roll drive Extricable and exchangable roller cartidges for easy maintenance Quickthreading feature for universaljoint shafts Movable base Manual or hydraulic loop bridge Conveyor belts... etc.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

For the automation of your production, we develop and build semi or fully automatic hydraulic punching systems, tailored to your special wishes and needs.

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

EH 25-H JDN Hydraulic Monorail Hoists Carrying capacities: 20 t up to 100 t Our hydraulic hoists can be deployed as an alternative to air driven units in all places where hydraulic lines, central hydraulic systems or hydraulic aggregates are existent. Standard Features predestined for application in explosion-endangered areas (Explosion protection) super-silent encapsuled and robust gear motor integrated overload switch-off only two supply connections at hoist “P” and “T”, leakage oil drained internally

Request for a quote

J.D. NEUHAUS GMBH & CO. KG

Germany

PROFI 6 TI-H JDN Hydraulic Hoists PROFI Carrying capacities: 3 t up to 100 t Our hydraulic hoists can be deployed as an alternative to air driven units in all places where hydraulic lines, central hydraulic systems or hydraulic aggregates are existent. Standard Features predestined for application in explosion-endangered areas (Explosion protection) super-silent encapsuled and robust gear motor integrated overload switch-off only two supply connections at hoist “P” and “T”, leakage oil drained internally

Request for a quote

GSW SCHWABE AG

Germany

Please contact us for more information on our program of DieClamps, Roller Bars, Consoles and individual Roller Components. We will gladly furnish a quotation for your specific need for you. Our offer included hydraulic power systems as well.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

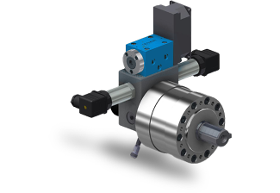

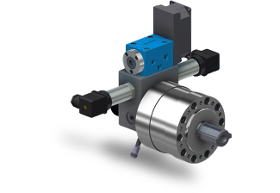

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The use of servo-hydraulic controls can significantly extend the range of applications for swivel motors. Larger loads can be slewed in a shorter time than is possible with purely hydraulic systems, where the damping travel is fixed. In conjunction with such a control system, the acceleration and braking behavior of the swivel motors can be specifically adapted to the requirements. This means that even fast and very precise movements with large masses can be safely mastered. We offer customized solutions for a wide range of applications. Our qualified team will be happy to advise you on design and realization.

Request for a quote

BAUER GMBH

Germany

-driven by forklift hydraulic system -variable gritting range; can be adjusted by varying height and angle of inclination of mast -stirring mechanism -protective grid as cover -fork sleeves for pick-up by a forklift truck

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

INDIVIDUAL SOLUTIONSIf you are searching for a custom solution for your mass finishing processes, the TT...B series is the best choice. The modular system allows you to fit the individual machines with feeders, screening machines and abrasive media return transport systems as required. ELECTROMECHANICAL OR HYDRAULIC SYSTEMS AVAILABLE The work bowl can be pivoted either electromechanically (TT 25, TT 45) or hydraulically. You can also partially automate processing with the respective peripheral devices such as feeding and separating units. THE BENEFITS AT A GLANCE Individual mass finishing solution Modular system Choose from electromechanical or hydraulic system Partial automation possible

Request for a quote

BAUER GMBH

Germany

-sturdy frame with fork sleeves and release mechanism -can be secured to prevent slipping -pallet cage is secured by a tension fixture -a steel cable holds the lid open -forward and backward movement -restrictor valve enables smooth regulation of the emptying speed -fixture to hook up hydraulic hoses, steel cable and safety chain -Finish: hot-dip galvanized Types available -Type KG-A, emptying is controlled by the forklift hydraulic system -Type KG-B, manual emptying and adjustable dumping brake -Type KG-C, manual emptying

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Following product changes or a surface defect detected by the monitoring equipment, the aected mat section has to be rejected and discharged in time before reaching the ContiRoll®-infeed. This is ensured by Siempelkamp’s reject mat system. It is an in-line element of the forming line. Thanks to its modular design, it can be adjusted to the product parameters, enabling reliable press protection and a quick and material ecient plant restart. Features Drive/reject mat unit including track support Reject mat hopper Integration in the belt drive station Motor-adjustable table including belt deection nose Motor-adjustable belt cleaning brush Advantages Distance-controlled activation for an optimised material discharge and minimised rejects volume Options Including disintegrating rollers Including dust ap Hydraulic reject mat drive Nose stroke 3000 mm or 4000 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OGE GROUP

Germany

Power Hydraulic Unit 7 Pumps and Oil Tank

Request for a quote

OGE GROUP

Germany

Hydraulic Unit 4 Pumps and Tank

Request for a quoteResults for

Hydraulics systems - Import exportNumber of results

20 ProductsCompany type

Category

- Electric motors and parts (7)

- Gas and oil - exploitation (3)

- Metal straightening machines (2)

- Hydraulic tools (1)

- Dustbins, waste bins (1)

- Grinding - steels and metals (1)

- Machine tools, metal shaping - parts and accessories (1)

- Punching machine tools (1)

- Salt spreaders (1)

- Wood veneer - machinery and equipment (1)