- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- drilling and milling machines

Results for

Drilling and milling machines - Import export

SAMAG MACHINE TOOLS GMBH

Germany

TBM flex – special deep drilling and milling centers – deep drilling and milling in one machine Modular system for drilling and milling For individual part and small series production Peeling and rolling possible Processing of forklift forks, telescopic forks, aircraft landing gear parts, special screws, special cylinders.

Request for a quote

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL multi-roller tools are usually used for roller burnishing. Types G, R and RA machine cylindrical through and blind bores, stepped bores and cylindrical external surfaces including similar non-cylindrical surfaces. . RP, RK, RKA and RKAK tools are designed for plane surfaces, cones and spherical surfaces. RH/RHA tools deep roll fillets and chamfers. FA tools deep roll large thread root radii. All ECOROLL multi-roller tools can be used on CNC turning, drilling or milling machines and machining centers or on conventional machine tools. They can be characterised by reliable functioning and high precision. Adjustment of diameters is very convenient, and only nominal lubrication is required. Futhermore, replacement of wear parts is very simple. This uncomplicated maintenance and short primary processing times enable significant time savings.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Digital readouts from HEIDENHAIN are used in a wide variety of applications. They are deployed on machine tools, infeed axes on saws and presses, measuring and inspection equipment, dividing apparatuses, setting tools, production inspection measuring stations, and more. To meet such demands, these digital readouts can also be used in combination with numerous encoders from HEIDENHAIN. Digital readouts with multiple axes are primarily used on manually operated machine tools, where their practical cycles provide optimal support to the operator during milling, drilling, or turning. By instantly displaying the position in an easy-to-read manner, digital readouts enable a significant increase in productivity.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling and boring machines, as well as machining centers. While the controls have undergone continuous development during this period, the basic operational technique has remained the same. You will find also these principles implemented in the TNC 640, the HEIDENHAIN contouring control for milling and milling/turning operations: shop-oriented programmability with graphic support, many field-proven cycles and an operational design you'll recognize from other HEIDENHAIN controls. Shop-oriented programming You program conventional milling and drilling operations, and with the TNC 640 also turning operations, yourself at the machine, in plain language dialog—the workshop-oriented programming language from HEIDENHAIN. The TNC 640 provides you with optimum support with practical prompts, questions and expressive graphical aids—for turning operations, too.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TNC 620 is compact and easy to read. The TNC 620 is a compact but versatile contouring control for up to five controlled axes. Thanks to its flexible operating concept—workshop-oriented programmability with HEIDENHAIN conversational programming or offl ine programming—and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for the following: Series and single-part production Toolmaking Machine building Research and development Prototypes and pilot plants Repair departments Training and education facilities And it offers the applicable features both necessary and helpful: Universal milling machines Free contour programming Milling cycles for complex contours Fast presetting with HEIDENHAIN touch probes Drilling and boring machines Cycles for drilling, boring and spindle alignment Cycles for linear and circular point patterns Five-axis machining with swivel head and rotary table

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Thanks to its flexible operating concept – workshop-oriented programmability with HEIDENHAIN conversational programming or external programming – and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for series and single-part production tool and die making manufacture of machines research and development prototype production and testing facilities repair departments educational and training institutes The TFT 15-inch color monitor shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control such as program blocks, comments and error messages. More information is provided through graphic support during program entry, test run and actual machining. The selectable split-screen display shows the part program blocks in one half of the screen and the graphics or the status display in the other half.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TS workpiece touch probes fromHEIDENHAIN help you perform setup, measuring and inspection functions directly on the machine tool. The stylus of a TS touch trigger probe is defl ected upon contact with a workpiece surface. At that moment the TS generates a trigger signal that is transmitted either by cable, an infrared or radio beam to the control. The control simultaneously saves the actual position values as measured by the machine axis encoders, and uses this information for further processing. HEIDENHAIN touch probes are available in various versions for workpiece measurement on machining centers, milling, drilling, boring machines and CNC lathes.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. The Yaskawa servo motors installed on all axes bring speed and precision to the production process. Versatile application possibilities: drilling, cutting or engraving in materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

CNC-STEP GMBH & CO. KG

Germany

Thanks to the robust steel frame, our T-Rex CNC mill enables you to produce precisely, quickly and cleanly. Even with workpieces made of hard material, you will achieve ideal results, thanks to the high stability of the CNC machine, which is guaranteed by the robust construction. On this machine, you can even process thicker plate material, as the clearance height of the Z-axis is 200 mm. Versatile application possibilities: drilling, cutting or engraving in different materials such as plastic, wood, granite, marble, stone and metal can be done with high accuracy. Basic equipment: > vacuum table with several zones > manual central lubrication > KinetiC-NC control software > ergonomic control panel with integrated CNC control > full version of the design software ConstruCAM-3D > Estlcam software CE-compliant commissioning of our CNC machines requires the attachment of the protective housing and the exhaust connection.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Highly Sensitive Sensor Equipped Side Slip and Inclination detected by a builtin sensor Selfcheck Function The machine checks for faults itself Total Weight Just 7 kg Weight reduced by utilising a moulded plastic Housing Powered by a Battery It makes it possible to drill holes anywhere Magnetic Force Control Function The magnet force is automatically reduced when the drill is not running Soft Start Function The large electric current on startup is prevented by starting the electric drill gently Automatic Drill Stop and Warning Function Unnecessary operations are eliminated

Request for a quote

F. ZIMMERMANN GMBH

Germany

With the FZ100 Portal Milling Machine Zimmermann has managed to achieve 6-axis machining using the patented in-house developed M3ABC 3-axis Milling Head. This concept sets new standards in the volume machining of aluminium, composite and model making materials as well as in the High Speed Cutting of steel and cast iron, where conventional 2-axis fork heads with A- and C-axis have long reached their limits in the 5-axis simultaneous machining. Advantages: - Machining four times faster is possible - Perfect quality thanks to the six axes - Highest accuracy possible

Request for a quote

F. ZIMMERMANN GMBH

Germany

The 5-axis portal milling machine FZ 25 is a universal solution for the machining of highly complex and at the same time voluminous components. Model materials as well as composites through to light alloys can all be machined with this HSC gantry machine. This machine range fulfils the specific requirements of many sectors: - In the automobile design where large models need to be produced (e. g. cars on a scale of 1:1). - In pattern and tool making, especially in connection with very large workpieces with deep contours need to be machined (e. g. large rotation-symmetric moulds such as tanks and pools, etc.). - In the boatbuilding and shipbuilding industries, where huge work areas are required in all three axes, since the components are often elongated in shape. - In the aircraft industry, e. g. for milling panels, other large parts and components with extreme contours. In the wind energy industry with its long thin blades and bulbous hubs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

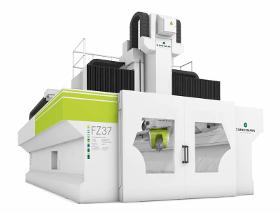

F. ZIMMERMANN GMBH

Germany

Universal metal cutting machine. Designed for highly dynamic machining of different materials. High-speed machining ensures efficient milling results. Advantages: - outstanding price-performance ratio - very broad application spectrum - high-quality universal head for simultaneous machining

Request for a quote

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The FZ33 compact combines a wide range of applications with excellent price/performance ratio and proven Zimmermann technology. Take advantage of these features for economical machining for a wide variety of parts for Aerospace, Automotive, Tool and Die, as well as many specialty applications. The rigid monolithic structure eliminates special foundations and provides a cost-effective and variable installation in small spaces. Focusing on the power spectrum to machine small and medium size parts, Zimmermann sets new standards and guarantees the user an enormous amount of flexibility and value – in other words, a low business risk due to an attractive cost price, stable machine value and thanks to its flexibility ensured added value.

Request for a quoteResults for

Drilling and milling machines - Import exportNumber of results

21 ProductsCountries

Company type

Category

- Milling - machine tools (9)

- Drilling - machine tools (4)

- Numerical control systems - minicomputers and mainframes (3)

- Measurement - Equipment & Instruments (2)

- Mechanical engineering - custom work (1)

- Mechanical transmission - components (1)

- Milling - woodworking machinery (1)

- Polishing - steels and metals (1)