- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- gas mixing

Results for

Gas mixing - Import export

UNITED PROCESS CONTROLS GMBH

Germany

The RCV Plus™ Gas Mixing System is a combination of flow meters specifically designed to monitor and control the ratio of two gases. It consists of an RCV Plus™ and a FLO-TRONIC Plus™. The RCV Plus™ utilizes a micro-processor that continuously compares a preset ratio to the real-time ratio of the two gas flows, as measured by the FLO-TRONIC Plus™, and the ratio control valve itself. Using a stepper motor, the RCV Plus™ continuously adjusts the flow metering needle-valve to precisely maintain the preset gas ratio. The real-time ratio is continuously displayed on the LCD screen of the RCV Plus™. Included in the RCV Plus™ is an optional input for the addition of a trim gas, which is frequently used for process control. Trim gas addition is additive to the ratio. When trim gas is used, the continuously displayed real-time ratio then includes the trim gas addition.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

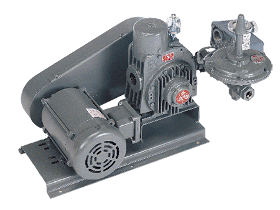

Gas Mixing Panels include the Waukee brand rotary vane compressors, air and gas Flo-Meters, and either a mechanical carburetor or RatioProver for precise ratio control. Panels are available with additive trim gas or air Flo-Meters. FEATURES: • Available with Lubed Vanes (includes a set of Phenolic Vanes and an Auto Lubricating System) or Non-Lubed Vanes (includes a set of Long Life Composite Vanes) • Available with outlet pressures ranging from 0.5-5.0psig. For higher pressures, consult UPC. • Two options available for ratio control: Standard Carburetor, RatioProver • Available with output capacities ranging from 200-12,000CFH • Available with Built-in Unloader for pressures between 0.5-2.5psig or with Bypass Relief Regulator for pressure lower than 0.5psig or higher than 2.5psig • Available with Standard turndown of 2:1 or 10:1 when used with a Compressor Pressure Controller • Includes Gas and Air Flo-Meters and Air Filter • Available with Trim Gas or Air Flo-Meters

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Despite the increasing level of digitalization, an ever-increasing demand for paper and pulp products can be observed. However, a shift is taking place from print paper qualities to packaging paper and cardboard. The wide range of paper products requires a variety of production processes. These include mechanical and chemical processes which, depending on the form and variant, produce different pulp qualities. Stirring and mixing are essential unit processes in all types of paper and pulp production. Mixing tasks range from liquid/liquid or gas/solid/liquid mixtures, through mixing of complex liquids, and include mixing of chemically reactive components. Improving and optimizing mixing processes in the paper and pulp industry can lead to end product improvements; such as increased strength, improved luster, or significant energy or chemical savings.

Request for a quote

KELVION HOLDING GMBH

Germany

The EGR Cooler, developed in close collaboration with our customers for medium and low speed engines, ensures that the recirculation exhaust-gas is mixed at the lowest possible temperature with the air for the combustion process. EGR Coolers are an essential element of EGR systems for the next engine generation which already now fulfills future emission guidelines according to IMO (International Maritime Organization), EPA (US Emission Protection Agency), EURO, etc. We have developed various cooler designs with regard to the different requirements of EGR Coolers at 2-stroke and 4-stroke engines. The patented design for 4-stroke engines high pressure EGR system enables cooling of exhaust gas, some of which are over 700 °C, down to 50 °C.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Mixor™ is a precision compressor-carburetor device which accurately mixes gas and air in any selected ratio, and compresses it for use with endothermic cracking, or exothermic cracking generators, or as a source of pre-mixed gas and air for torch brazing, flame heat treating, or sort metal melting.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROCESS CONTROLS GMBH

Germany

The EndoInjector™ is a precise gas mixing / control system for endothermic gas generators. It incorporates a patented fuel injection design that utilizes electronic flow measurement and precise ratio control to consistently provide the ideal gas mixture for high quality endo gas generation. The fuel injection design automatically delivers gas mixture on demand, providing only as much endothermic gas as furnaces require to reduce operating costs and eliminate gas waste. EndoInjector™ typically pays for itself in less than 1 year. The ExoInjector™ is designed specifically for exothermic gas generators. While similar in concept, the ExoInjector™ differs from the EndoInjector™ in that it comes in modified mechanical versions to accommodate pre-mix or nozzle-mix burners with a custom HMI software that allows for predefined ratio set points for burner ignition, rich exo, and lean exothermic gas. The system can be modified to provide hydrogen content control and water vapor monitoring.

Request for a quote

HILGENBERG GMBH

Germany

This compact micro torch is ideally suited for melting the ends of sample tubes precisely and safely. As a very small flame can be adjusted, it is possible to melt the capillary precisely at a defined point without excessively heating the remaining capillary, as is the case with standard torches. The torch is operated with a hydrogen/oxygen or a propane/oxygen mixture, both of which provide a very hot flame that even permits quartz glass to be processed. This torch is an extremely versatile tool with which practically all types of glass can be processed – from simple flaming to highly complex tasks. Features of the micro torch Fine, concentrated needle-point flame High heating capacity Mixed-gas operation Two separate needle valves Complete with fine nozzles Torch length >130 mm (without nozzle) Operating principle The torch consists of a gas mixing chamber and two gas inlets, which are also suitable for aggressive media such as hydrogen and oxygen. Two needle valves at the...

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The NDIR bundle N2O is made up of optimally matched thin film infrared emitters and a corresponding IR thermopile detector to measure nitrous oxide in gas mixes. The kit has a short delivery time and therefore achieves measurement results in a short time. This is especially an advantage for developers in research projects with a limited time span. The two-channel detector's optical filter has been optimized for the absorption spectrum of N2O (CWL: 4525 ± 20 nm / HBW: 83 ± 6 nm) and can provide important data, especially in the analysis of exhaust gases in the automotive, railway and marine sectors, the monitoring of industrial exhaust emissions and environmental monitoring.

Request for a quote

MICRO-HYBRID ELECTRONIC GMBH

Germany

The NDIR bundle N2O is made up of optimally matched thin film infrared emitters and a corresponding IR thermopile detector to measure nitrous oxide in gas mixes. The kit has a short delivery time and therefore achieves measurement results in a short time. This is especially an advantage for developers in research projects with a limited time span. The two-channel detector's optical filter has been optimized for the absorption spectrum of N2O and can provide important data, especially in the analysis of exhaust gases in the automotive, railway and marine sectors, the monitoring of industrial exhaust emissions and environmental monitoring.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

The use of protective gases is an essential element of precise quality control (HACCP) in food packages (Modified Atmosphere Packaging = MAP). MAP gas mixers by WITT provide controlled gas quality and safety in your packaging process – for germfree and preserving food. WITT offers gas mixing and metering systems for all packaging machines used in the food industry, no matter if vacuum packaging, thermo forming, flow pack or chamber packaging machine. The gas mixing systems are adjusted to your specific product type and processing and require only basic installation requirements. WITT system solutions are developed in close collaboration with national food and research institutes. WITT is approved and certified according to ISO 22000 for food safety.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quote

LICHTGITTER GMBH

Germany

The surface of the perforated metal plank, type BN-GA is a mix of closed punched nobs facing upwards and conical drain holes facing downwards. This means that the grating does not have any sharp edges on top and can be walked on easily even without footwear. At the same time, however, any liquids can be quickly drained through the conical drain holes so that no hydroplaning can occur.

Request for a quoteResults for

Gas mixing - Import exportNumber of results

13 ProductsCountries

Company type