- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical components

Results for

Electrical components - Import export

LLOYD DYNAMOWERKE GMBH

Germany

From the project planning stage through to the end of their operating life we offer a range of concepts for economical and fault-free operation of your machines Target-oriented maintenance intervals to match the respective operating conditions Online and offline status monitoring Trend measurements relating to wear behaviour of the mechanical and electrical components Stocking spare parts for shorter downtimes Training for maintenance staff 24 hour service Company-oriented maintenance contracts Modernisation of the machine, controllers and protection equipment Environmentally compatible recyclingTesting of electrical machines and systems, type tests, system tests, heat run tests according to DIN standards Dynamic balancing or rotors Cleaning and oven drying of large machine parts such as stators or rotors VPI impregnation with rotating hardening process in drying oven VPI impregnation of transformers and large coils VPI or resin-rich coil production Manufacture of tooth-wound coils

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts made by brass, then after colorful plating, the products mainly used in electronic product field.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the E-cigarette shell which is machining by aluminum,then after special knurled,brown plating ,its nice appearance makes it very popular.

Request for a quote

FEINMETALL GMBH

Germany

Feinmetall test connectors are available for many interfaces such as RJ, USB, HDMI and others. They can be installed very easily and effectively in test fixtures and test modules.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. This electrical test process is ideal for testing smaller numbers of units, such as for pre-production, prototype or pilot series. The rapid test creation process allows, among other things, flexible reaction to product changes. Flying probe tests can be rapidly set up and are cost-efficient.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

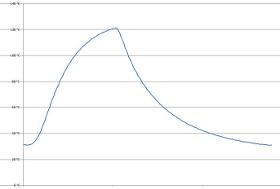

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. In our test laboratory, we are able to carry out static and cyclical environmental simulation for you, from air-to-air and liquid-to-liquid thermal shock tests to storage temperature and humidity tests. Based on the environment in which the product is to be deployed, we will draw up a tailor-made quality assurance programme. Through simulation of the conditions that cause ageing (e.g. large temperature fluctuations) we can ensure that the product will reach the required service life. Products are also subjected to further customer-specific tests in fields such as EMC, overload resistance and mechanical loading.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. For components of the most varied shapes and with diverse electronics components, we will set up our AOI stations according to individual needs and provide reliable optical control of the overall assembly. Automatic optical inspection of your components is naturally part of our service range.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Whether it's manual soldering with robotic support, wave and selective soldering or laser soldering – in all assembly tasks, we are able to use any technique required without a problem. Depending on the component, different soldering technologies offer different advantaged. We will adjust the process individually to your project.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). At PRUFREX, single-chamber and multi-chamber coils can also be achieved using two-wire windings. For specific magnetic flux requirements, we apply wires of different thicknesses to the coil form. Two different wire thicknesses, from 0.045 to 0.71 millimetres, on coil forms with press-in ferrite or metallic cores.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). We can wind onto any desired coil form using many different press-in ferrite and metallic cores. Multiple tap coils are also possible. Pins are automatically applied to the coil connections during the winding process, with wire drawing electrically controlled. Our winding machines handle single-chamber and multi-chamber coils with wire thicknesses from 0.045 to 0.71 millimetres.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Our fully automated winding centres for fine and self-bonding wire make us the perfect partner for any tasks you require. Our coils are tinned with lead-free coatings (RoHS). To manufacture self-supporting coils, we use self-bonding wire. During winding, the surface of the wire is bonded using hot air. To ensure the coil connections can be soldered, they are then stripped of insulating enamel using a fully automated milling process. PRUFREX is able to make air core coils with wire thicknesses from 0.045 to 1.6 millimetres.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This thermocouple extension can be used for any thermocouple with type “K” mini plugs. Selecting these high-grade components achieves long service lives.

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This thermocouple extension can be used with any Type K thermocouple. The selection of high-quality components ensures a long service life.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

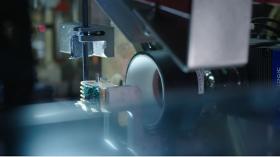

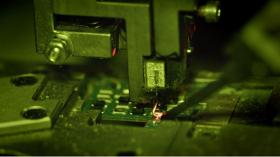

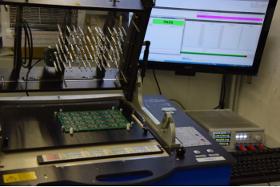

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Test contacts on the circuit board, produced for just this purpose, are contacted by fine, spring-loaded test pins. Depending on the series size, the in-circuit test can take place manually or in an automated fashion. In combination with other test processes, including tests without test contacts, over 90 percent of all errors can be detected.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

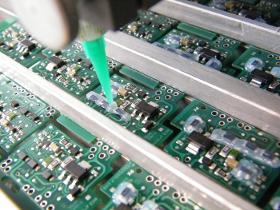

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Dispensing technologies allow us to adjust your components to additional requirements. Our range of services covers all dispensed materials, from adhesives through heat-conducting pastes to silicones. Depending on your project requirements, we offer you the most efficient routes to implementation – from manual production to CNC cells.

Request for a quote

FEINMETALL GMBH

Germany

Contacting WLCSP, SiP or flipchip wafers requires probe cards that can tolerate high currents while ensuring high signal integrity. The FeinProbe® addresses these applications perfectly.

Request for a quote

FEINMETALL GMBH

Germany

Probe card with lamella contact elements, especially suitable for RF applications with a high design variety.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FEINMETALL GMBH

Germany

New version of vertical contact technology with focus on increased service life and other advantages.

Request for a quote

FEINMETALL GMBH

Germany

Adaptable to an enormous range of applications, the ViProbe® is a proven buckling beam technology for more than 25 years, valued above all for its uniquely easy reparability.

Request for a quote

FEINMETALL GMBH

Germany

At the limit of what is possible: Reliable contact probes for finest structures and semiconductor contacts down to 40μm pitch.

Request for a quote

FEINMETALL GMBH

Germany

Clever designed contact probes, threaded probes, switch probes, step probes, push back probes - the perfect contacting solution for each application.

Request for a quote

FEINMETALL GMBH

Germany

Large variety of contact probes (pogo pins) for contacting PCBs even at difficult contacting conditions, different sizes, tip styles and spring forces available.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Whether an individual circuit board or full-scale, demanding device assembly – PRUFREX will manufacture your products to your individual specifications and quality guidelines. Component placement requires individual approaches. Our range of solutions covers small series produced by hand, medium-size series using semi-automated wave soldering machines and fully automated production lines for large-scale manufacture. We adjust the level of assembly automation to your project – so that you achieve the best result both economically and technically.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Smart automation concepts enable us to meet the highest standards of manufacturing. Our products are manufactured in Germany and made in USA, in a cost-efficient manner. Benefit from our production expertise that has been continuously developed over many decades. Mechanical protection, reliable electrical insulation, moisture shielding and heat dissipation - with continuously optimized potting resins (polyurethanes, epoxies, etc.) and potting equipment, PRUFREX is a leader in the field of vacuum potting. When it comes to the safe protection of your electrical and electronic components, our state-of-the-art, automated manufacturing equipment meets all contemporary requirements. The use of specially adapted epoxy and polyurethane potting compounds ensures excellent potting characteristics and the best-possible impregnation of components and coils. These optimised potting compounds also contribute to optimal heat dissipation.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

Alongside the standard ICT/FCT process, we can also target every individual production stage for verification, as requested. Efficient inspection strategies and final functional tests are a fixed component of our quality management system. PRUFREX is a manufacturer of test systems and software. In close collaboration with our own test equipment developers, we manufacture beds of nails for the in-circuit test (ICT) and functional test (FCT), alongside test equipment and production aids. Using the entire range of available test procedures, we will develop a strategy that suits your product.

Request for a quote

FEINMETALL GMBH

Germany

Contacting of all common RF connectors: For frequencies up to 20 GHz, with smart design for highest reliability and easy mounting.

Request for a quote

FEINMETALL GMBH

Germany

Four-pole measurement at minimum space: coaxial contact probes with inner conductor as sense pin, from smallest pitches up to highest currents.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. When planning tests, we work to your test specifications or develop a cost-optimised, efficient concept. In our tests, we simulate real usage conditions. In this way, we make sure that devices, systems or components will function correctly. Quality management at PRUFREX also includes developing efficient testing strategies.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quoteResults for

Electrical components - Import exportNumber of results

301 ProductsCountries

Company type

Category

- Electrical & Electronic Components (88)

- Electrical components and parts (81)

- Industrial cabling (35)

- Electric and electronic components - machines for manufacturing (32)

- Electronic components (22)

- Cars - electrical and electronic parts and components (15)

- Ceramic, components - electric (12)

- Carbon and graphite - electrical components (10)

- Copper and copper alloys (8)

- Control boxes - electric (3)

- Building hand tools, non-power (3)

- Coil winders (3)

- Automation - systems and equipment (2)

- De-humidifying equipment (2)

- Mechanical engineering - custom work (1)

- 3D scanner (1)

- Blast cleaning equipment (1)

- Cabinetmaking - machinery and equipment (1)

- Car tuning equipment (1)

- Connectors, electronic (1)