- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- water systems

Results for

Water systems - Import export

FLOTTWEG SE

Germany

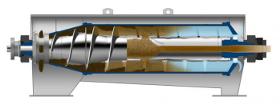

The demands on the quality and efficiency of sewage treatment plants are growing from year to year, not least due to rising energy and disposal costs. As a result, using decanters to dewater sludge means using state-of-the-art technology. The C-series decanters from Flottweg achieve high performance with reduced energy consumption. Flottweg Wastewater Decanters offer advantages over other processes and competitors' machines: ► High dry solids values in the discharged material ► Higher power density within a small footprint ► Powerful Flottweg Simp Drive® drive ► Reduction of operating costs due to reduced need for flocculant ► Additional energy recovery with the Flottweg Recuvane® system ► Economical bowl and scroll drive ► duces the energy consumption of your decanter by 10 to 30 percent

Request for a quote

FLOTTWEG SE

Germany

Innovationen sind Flottweg Spezialität. Unsere Xelltorbaureihe spiegelt Erfindergeist, langjährige Erfahrung und technisches Know-How in einer Maschine wieder. Auf Kläranlagen ausgelegt ist die X5E für mittelgroße Kläranlagen die optimale Lösung, wenn es um Schlammentwässerung und Schlammeindickung geht. Die Kosteneinsparung hinsichtlich Entsorgung und Transport ist für viele Kläranlagenbetreiber der ausschlaggebende Punkt, sich für den Flottweg Xelletor zu entscheiden.

Request for a quote

FLOTTWEG SE

Germany

Flottweg C series decanters around the world process 25 million liters of sewage sludge per hour. The dewatering and thickening of sewage sludge plays a decisive role in the wastewater treatment process. Requirements for the quality and efficiency of sewage treatment plants increase year after year, not least driven by the increasing costs of energy and disposal. As a result, the state of the art is now to use decanter centrifuges to dewater and/or thicken the incoming sludge. Flottweg developed the decanters of the C series especially for this purpose. The C7E represents the largest of all the C machines. The C7E increases the proportion of dry substance in the sludge, thereby reducing its volume and weight (due to loss of water). That means that operators need to dispose of, recycle, or burn less sludge. The result: enormous potential savings for the operators of sewage treatment plants.

Request for a quote

FLOTTWEG SE

Germany

Proven know-how meets state-of-the-art technology. This is the best way to describe the new Flottweg decanter C series. We also have the optimal solution for the very large wastewater treatment plants. The combination of our own Simp Drive® drive system, which has been in use since 1994, and Recuvane®, which allows flexible and simple retrofitting as well as targeted discharge of the centrate water, sets new standards for Flottweg in separation technology.

Request for a quote

FLOTTWEG SE

Germany

In the process of treating waste water, fine biological sludge is constantly produced during the decomposition process at a sewage treatment plant. For a stable decomposition process in the biological treatment phase, the sludge produced in the secondary sedimentation pond, also known as excess sludge, is removed and fed into the digestion tower. Flottweg's OSE decanters thicken the sludge before it enters the digestion tower. Sewage treatment plants benefit from an even feeding of the digestion tower and can thus optimally use the volume of the digestion tower. The Flottweg OSE decanter is specially designed for sludge thickening. ► Highest gas yield through constant feeding of the digestion tower ► Best possible thickening even with changing feed conditions ► Larger sedimentation volume (due to deep pond and steep cone) enables highest power density (10 - 20 percent) with minimum space requirement

Request for a quote

FLOTTWEG SE

Germany

Flottweg has developed a unique centrifuge concept especially for the high-level dewatering of sewage sludge: The Flottweg Xelletor series. For the wastewater treatment plant operator, dewatering offers enormous savings potential. The costs for transport and disposal of dewatered sewage sludge often account for 80% of the operating costs of mechanical dewatering. The dewatering performance of the Xelletor machine is significantly better than that of our predecessor models. And it's setting new standards in terms of throughput, dry substance, and polymer and energy consumption.

Request for a quote

FLOTTWEG SE

Germany

Honored with the German Innovation Award 2019, the Xelletor series is one of the greatest achievements in the field of sewage sludge. Dewatering sewage sludge is standard for wastewater treatment plants and since it usually has to be transported away, operators have an interest in separating as much water as possible from the sludge. This saves weight and thus reduces costs. Savings of up to 10% in sludge volume and 34% in energy consumption are possible. Our Xelletor high-performance centrifuge inspires customers all over the world with the many years of technical know-how and innovative spirit behind it.

Request for a quote

BOSCH INDUSTRIEKESSEL GMBH - INDUSTRIAL BOILERS

Germany

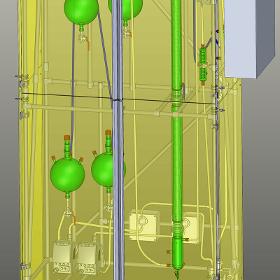

— Water treatment for steam boiler systems — Prevention of corrosion in the boiler — Outstanding deaeration efficiency and reduced consumption of chemicals with WSM-V complete deaeration system — Partial deaeration module WSM-T for small systems — Fast and easy planning, installation and acceptance appropriate to the steam boiler in question — Requirement for positive suction head allows for ground-level installation and easy commissioning

Request for a quote

MANUFAKTUR VON DOBERSTEIN

Germany

Jumping jet systems produce spectacular computer-controlled water effects paired with exclusive lighting effects. The water jet rises from the opening and flies as cut on a predetermined parabolic orbit accurately in a small collecting opening. In this case, the transparent water jet is continuous or cut in different lengths representable. This can be the combine different water launch variants. Accompanied by state-of-the-art LED technology, the jet of water appears to fly independently in a variety of variations. Jumping jet systems can be operated in the indoor and outdoor areas alike.

![Distillation Control System ILUDEST® [DC / MoS]²](/filestore/vig280/opt/product/ea/9a/distillation-control-system-dc-mos2_3ede0556.jpg)

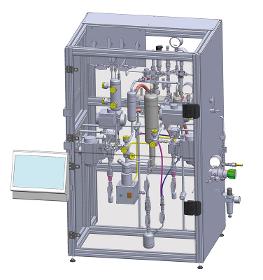

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

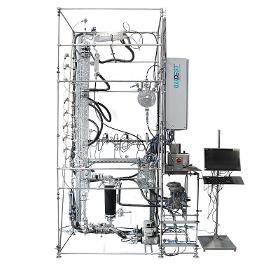

The use of a computeraided system is well suited for the control and regulation of distillation and rectification plants the wide range of measurement and regulating tasks, the need for flexibility, ease of operation and a display of the operating parameters make the use of a computer with the relevant software and peripherals appear the ideal solution.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Comprehensive range of microprocessor operated units for various control modes/functions. The indication and modification of all set points and actual values is done via touchscreen LCD. With optional Ethernet interface for the communication with a PC and CANBUS for the connection to other controller types.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

ILUDEST® designs / manufactures a comprehensive range of Teaching Units for the Thermal Process Engineering, e.g. Continuous distillation Thin film evaporation Short path evaporation Pulsed counter current extraction Absorption/desorption Residence time determination (reactor/cascade) etc. Other types and/or customized versions are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

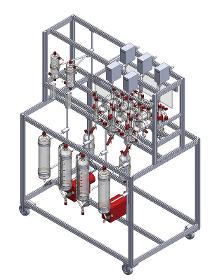

For liquidliquidextraction according to the MixerSettlerprinciple, design acc. to Dr. E. Müller (Lurgi). With screw stirrer for intensive mixing of the phases, especially suited for metallic salt extraction. Pumping capacity and residence times are changed by adjusting the stirrer speed. An additional advantage of the unit is the application for extractions during which reactions of considerable density changes occur. Typical applications for this universal apparatus are metal salt extractions mixtures with low surface tension if the dispersed phase coalesces with difficulty if variation in residence time of the phases occur in the extraction stages if reactions are expected during the extraction process if considerable changes in density are expected as a result of extraction

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The unit for the liquid/liquid extraction operates in a countercurrent flow and is designed as a pulsed column with sieve trays and packing material alternatively. The working principle of this unit is based on the fact, that the two liquid phases are pressed through the holes of each sieve tray or through the packing respectively, forced by the used pulsation, thus one phase will be dispersed into the other. The large contact surface which will be formed by this specific design, makes the product exchange between the two phases highly efficient. During the return travel of the pulsator, the drops previously dispersed are agglomerating into a homogeneous phase. The light phase will be fed into the system at the lower end of the column, while the heavy phase is entering the tower at the upper end. Due to the gravitation, supported by the said pulsation, both phases are passing the column in countercurrent way and are withdrawn at the opposite ends.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Because of the thermal sensitiveness of products, this separation method is applicable. The medium which is to be distilled is exposed only for a very short time to the heating substances because the film, which is created by the wiper, can evaporate very quickly. The residence time of medium on the heating surface is a matter of seconds, thus essentially less than in a reboiler flask, circulating evaporator etc. Evaporators in borosilicate glass 3.3 are available with heat exchange areas 0.02…0.8 m². Alternative design versions in stainless steel for higher throughputs are available upon request. Please equire.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The instrument has a capacity of 6 litres of solvent mixture with a throughput of up to 1 l / hr (e.g. when recovering Xylene). A microcomputer controller holds up to 100 programs as well as monitoring the distillation process for normal and safe operation. Variable reflux ratios and equilibrium times are possible so that the operator has maximum flexibility to design a program for optimal efficiency. Other capacities are available upon request.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Especially the theoretically additional evaluation of the temperature and pressure dependence of phase equilibrium is insufficient very often in daily practice, thus the experimental determination of VLEdata is increasingly requested in the overpressure range, too. ILUDEST®/ iFischer® modified the VLEequipment, since decades sold under the worldknown FISCHER® brand, suitable for the overpressure range up to 50 bar. The VLEequipment is designed for a charge of 50 ml (dynamic mode) and can be operated under vacuum (1...1,013 mbar), atmcondition and overpressure (1...50 bar) as well as temperature up to 250°C. An extended operating range up to 100 bar is possible.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Scientists and chemical engineers still measure phase equilibria despite the significant improvement in theoretical evaluations. Therefore, our phase equilibrium apparatus is part of the standard equipment in chemical engineering laboratories. The vapourliquid equilibrium of binary and multicomponent mixtures constitute an essential basis for the determination of the theoretical plates necessary for the evaluation of separation processes. Although VLEdata are known from literature, there is still an increasing tendency towards redetermining equilibrium data by experiments, because the thermodynamic parameters like pressure, temperature and concentrations are different or inadequate. For designing e.g. extractive distillation processes the evaluation of vapourliquidliquid phase equilibria (VLLEdata) are required. The practical measurement and determination of these data proves difficult with the standardised VLEunits because of the phase formation of the liquids.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Automatic SemiMicroDistillationUnit with the FISCHER® SPALTROHR® Column Compact and especially versatile, the fully automated FISCHER® LABODEST® HMS 500 AC is a unit with highest separation efficiency A modular system, which can be designed according to specific requirements including an equipment for recording the distillation curve or for printingout the distillation record by means of a printer or for connection for electronic data processing. Technical Data Charge Quantity 10...500 ml Operation Temperature up to 200°C, with optional extension up to 350°C Operation Pressure Atmospheric or Vacuum 10 0...0.1 mbar Pressure Drop < 0.1 mbar Separation Efficiency up to 90 theoretical plates Mains Supply 230 V, 50 Hz Dimensions (w x d x h) 1.25 x 0.60 x 1.70 m Weight approx. 100 kg

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D2892/5236 CC or FISCHER® AUTODEST® 800/860 AC is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. Fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector (in the system section TBP with 20 receivers) includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The automatic fraction collector (in the system section Potstill with 12 receivers) includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC can be converted to the “HV” version by adding an extended Potstillcolumn to the standard ASTMsystem (Potstill). The respective distillation process is performed in the range of 0.005...0.1 mm Hg. The iFischer® DIST D5236 HV 6 ltr / FISCHER® AUTODEST® 860 HV 6 ltr is a fully computer controlled unit of turnkey design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. The system is also available with a capacity of up to 50 ltr.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

Fully Automated/Computerized Distillation System for fractionating of crude oil samples, atmospheric residues resp. vacuum distillations of lubricating oil samples up to very low operation pressure (high vacuum HV Operation pressures down to 0.005 mmHg, allowing fraction temperatures up to 600 °C AET). The unit is equipped with an automatic fraction collector (FC) and combined automatic fraction discharge into final receivers, which are closed automatically. The fraction volumes and weights are determined by builtin volume follower system and internal balance (included software "FCExtension" allows to operate very narrow fractions by using max. 40 receivers).

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D1160 CC / FISCHER® AUTODEST® 850 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The unit extends the current test method and does not limit your vacuum distillation testing options. You are able to define your own tailored program also beyond the current standard. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The design also grants an easy maintenance by the operator. The analysis protocol is printed out simultaneously to the distillation and the distillation curves in actual boiling temperatures (ACT) and atmospheric equivalent temperatures (AET) as well as essential distillation parameters are shown on the monitor. The final data and the distillation curves are printed and stored on harddisk.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The system is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. It is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 20 receivers includes a builtin internal balance for the determination of the fraction weight, while the separate volume follower system is used for discharging the fractions into the final receivers and the determination of the fraction volume as well as for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Numerous optional items available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D2892 MC/ FISCHER® AUTODEST® 800 MC is an automated, computer controlled and PC operated unit of turnkey design, ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. A respective design as per ASTM D5236 (Postill) is also available.

Request for a quote

ILUDEST DESTILLATIONSANLAGEN GMBH

Germany

The iFischer® DIST D5236 CC / FISCHER® AUTODEST® 860 AC is a fully computer controlled unit of turn key design, and ready for use after installation and commissioning. The system is fully housed and equipped with doors in the front and rear to satisfy safety requirements and to facilitate service aspects. The automatic fraction collector with 12 receivers includes a builtin internal balance, which is used for the simultaneous determination of the fraction weight and for the direct distillation rate control. The vacuum equipment and the control system are designed for highest accuracy, repeatability and reproducibility of data. Also available are the iFischer® DIST D5236 CC 50 ltr, 100 ltr, 150 ltr and 250 ltr fully automated computerised distillation systems acc. to ASTM D5236 equipped with a set of comprehensive safety features in correlation with the applicable EU Machine Directives and refinery standards. Numerous optional items available.

Request for a quoteResults for

Water systems - Import exportNumber of results

31 ProductsCompany type

![Distillation Control Unit ILUDEST® [DC / MIC]³](/filestore/vig280/opt/product/44/e3/dist-control-unit-iludest-dc-mic_1_e7dfd410.jpg)