- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steam turbines

Results for

Steam turbines - Import export

IMM MASCHINENBAU GMBH

Germany

CNC polishing of compressor blades and vanes to optimize flow efficiency while at the same time minimizing differences due to tolerances in blade geometry. This is essential to the balancing of the compressor rotor and the fit of the stator parts. The SPE allows to keep up with the demand of this for the latest F-Class & H-Class Gas Turbine Compressors. The SPE CNC-Machine allows automatic polishing of all rows of the Gas Turbine Compressor, as well as most rows of Steam Turbine Blades within tight tolerances and highest repeatability. A dedicated CAD/CAM software allows for generation of NC part programs. As the SPE is a cartesian type machine tool there is no need for referencing or time consuming in process gauging. The precision and repeatability of the process allows the balancing of the milling process to leave a rougher scallop on the blade and save valuable time and cutter on the milling side. Capable of polishing compressor blades, fan blades and vanes up to 550 mm in length.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS gland steam condensers: - Can be used in regenerative and conventional applications - A complete system including blowers - Materials are adapted to the relevant application - Acceptance currently according to PED 2014/68/EU and the ASME Code; additional certifications to follow

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Sunlight can also be channeled and focused to heat water, which can drive steam turbines in large-scale power plants. This Concentrated Solar Power (CSP) was once dominated by glass mirrors due to their unmatched reflectivity. Recent advances in aluminum reflectivity and brightness, partially due to our processing innovations, however, have made the material an effective substitute. Compared to glass, aluminum solar panels offer significantly lighter weight and better ratio performance versus cost.

Request for a quote

ZWP ZAHNRADWERK PRITZWALK GMBH

Germany

ZWP is one of the leading independent manufacturer in Germany for gears, pinions and rim gears. We supply already well-known manufacturers for gear boxes. We are looking forward getting intouch with you to have a conversation about possibilities for your supply. Sectors of our (international) customers are: Mining, Oil, Offshore, rail and ship transmissions, industrial transmissions, and many more fields of applications. Overview about the capabilities for production: Gears internal and external toothed hardened and grinded Module 2 – 50 mm Diameter 100 – 2,000 mm Internal toothed rings / rim gears hardened and grinded Module up to 20 mm - more on request Diameter 100 to 1,800mm Pinions and shafts internal and external toothed hardened and grinded Module 1 – 50 mm Diameter 50 – 500 mm Length up to 1,500 mm Hardening and balancing inhouse possible Cooperation with companies for special manufacturing of gears and pinions etc We speak English.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Application Used in Paper Factory

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Castrol Anvol PE 46 B (07.09.2020) Flame-retardant hydraulic fluid Description The flame-retardant hydraulic fluid Castrol Anvol PE 46 B is based on defined, hydrolytically stable phosphoric acid esters. Castrol Anvol PE 46 B is a hydraulic fluid to be labeled as HFD 46 in accordance with DIN 51 502 or as HFDR 46 in accordance with ISO 6743-4 . Castrol Anvol PE 46 B complies with VDMA standard sheet 24 317 "Guidelines for flame-retardant hydraulic fluids" (type HFDR). The liquid is PCB-free. Application Castrol Anvol PE 46 B is preferably used as a hydraulic fluid in electro-hydraulic control systems of steam turbines. It was developed specifically for this purpose. Used as a circulation lubricant, Castrol Anvol PE 46 B is suitable for bearing lubrication of steam and gas turbines, provided they are designed for this group of materials, and it is used as a hydraulic fluid in industrial hydraulics that work in fire-hazardous environments.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Assembly lubrication of screw connections of high-strength steel subject to high temperatures, corrosive influences in chemically aggressive environments, e.g. on gas and steam turbines in power plants, combustion engines, threads on pipe fittings, flange joints and fittings in superheated steam lines, exhaust pipe and combustion chamber screwed connections etc. Parting lubrication of materials with a tendency to seize up, e.g. V2A, V4A and high-temperature steels Advantages and benefits Excellently suited for preventing seizing and binding Highly effective against corrosion affects Free of lead compounds, sulphides, chlorides and fluorides For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner. Apply paste evenly in sufficient amount onto head/nut support and thread or onto the sliding areas with brush, spatula, etc.

Request for a quote

BORSIG GMBH

Germany

BORSIG has been manufacturing centrifugal compressors for process gases for almost 60 years. The BORSIG centrifugal compressor series comprises multistage integrally geared centrifugal compressors with up to 8 stages, with steam turbine, gas turbine or electric motor as driver with all auxiliary equipment (turnkey solutions) according to customer’s requirements. The compressors comply with the corresponding API design standards such as API 617 (chapter 3) and 672 (4th edition). The oil system is designed according to API 614 or manufacturer's standard. The development is based on the latest research results in fluid mechanics as well as in gear and bearing design.

Request for a quote

BORSIG GMBH

Germany

With around 160 years of manufacturing expertise in reciprocating compressors, BORSIG offers tailor-made horizontal and vertical compressor solutions for process gases with all auxiliary equipment (turnkey solutions). Our reciprocating compressors are driven either by electric motors, gas engines or steam turbines. They have been developed for heavy continuous operation with lubricated or non-lubricated cylinders. They comply with the design standards of API 618 (5th edition), API 11P/ ISO 13631 as well as other international and manufacturing standards. BORSIG reciprocating compressors stand for long life, high wear resistance and low life cycle costs.

Request for a quote

LLOYD DYNAMOWERKE GMBH

Germany

Synchronous generators from LDW are highly versatile and are used in shipbuilding, power stations and many other applications. Our generators can be driven by gas, steam or water turbines as well as diesel engines and other drivers. Synchronous generators from LDW have a high degree of efficiency and operate with extreme effectiveness. We develop and manufacture generators of the highest quality standards.LDW supplies synchronous generators with an output range from 4,000 to 60,000 kVA.Our synchronous generators are specially optimised for the specific application of the customer, e.g. if used for water power turbines with regard to runaway speed and turbine force absorption. Where diesel generator sets are used, the vibration load in particular is taken into account. On request, we will also construct the generator with a forged-on flange. A high degree of efficiency is ensured for all generators.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Boiler feed water The so called „Boiler feed water“ is stored in a feed water tank and continuously feeded to the boiler of a steam generator. A big quantity of feed water is needed for example in steam power plants. The boiler generates steam, which is used for heating, for chemical processes or for driving a steam turbine respectively a steam engine. The feed water is purified in a way, that all harmfull components for the boiler are removed or neutralized. Leakages and evaporation loss are compensated by additional water which is purified in the same way than boiler feed water. Very often, valuable well and potable water resources are used for the generation of process water. Environmental regulations restrict this usage of well and potable water continuously and increase the costs for this resources steadily. The conditioning of stream water to boiler feed water helps saving potable water and means cost advantages. The process of conditioning is based on ultra filtration with down

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

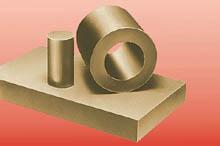

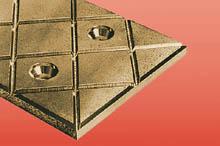

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quote

FEDERAL-MOGUL DEVA GMBH

Germany

Where to use deva.metal ® deva.metal ® is a self-lubricating bearing material manufactured by advanced powder metallurgy. It is fully compacted, unlike oil-impregnated porous bronze materials that are weak by comparison. deva.metal ® is provided with an evenly distributed solid lubricant throughout its metallic matrix. deva.metal ®, which is suitable for dry running at slow sliding speeds and high loads: has high resistance to temperature and corrosion. will tolerate contamination and edge pressures. can be easily machined if required. Applications Iron foundries and steel works, furnace construction, fans, foundry machinery, waste water cleaning plants, water, steam and gas turbines, pumps and compressors, food and beverage industry machinery, packing machinery, construction equipment, mechanical handling equipment and many more. Structure 1. Bronze, iron or nickel matrix 2. Solid lubricant (Graphite, WS 2 a.o.)

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Steam turbines - Import exportNumber of results

18 ProductsCountries

Company type

Category