- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling - steels and metals

Results for

Milling - steels and metals - Import export

ROCHOLL GMBH

Germany

We love a challenge so we are more than happy to take on special designs. We translate your specifications into top-quality products. In order to meet the most stringent requirements, we rely on our comprehensive machine park and on the production facilities run by highly specialized partner companies. These machines have been designed to manufacture both individual items and batches without any problems. Would you like to have more detailed information on our special designs? Why not contact us directly? We will be happy to assist you. Milling of profiles Special concrete designs Rings for placing Shore test specimens Milling of dumbbell test specimens for tensile tests Multiple test specimens according to DIN 53281ff Stainless steel rings for tests according to EN ISO 10563 Spacers for standard joints according to ISO 11600 Spacers for elongation test according to ISO 11600, made of aluminum or PMMA in various % values Feed mechanisms

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

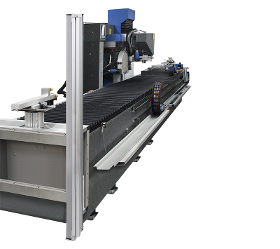

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

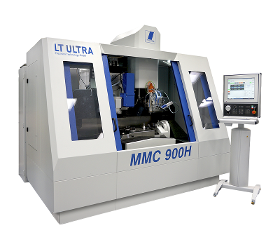

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs.Please do not hesitate to contact us.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

To create ideal conditions in terms of rigidity and damping for multi-axis machining, the series was equipped with hydrostatic (oil) bearings. By using diamond tools, optical surface quality can be achieved on a wide range of materials like crystals, nonferrous metals and plastics, even with complex geometries. Similar to the MMC 600/900 air bearing machines, the basic setup can be equipped with various accessories. The basic setup consists of 3 linear axes and can be upgraded by additional rotary, tilt or spindle axes to 4, 5 or 6 axes. Accessories, like different spindles, vacuum chucks, palleting systems, 3D touch probes for workpiece measurement, tool changer and automated tool setting, allow an effective use of the machine. Besides further accessories, there is the possibility to develop customized solutions, to adapt the machine to your needs. Please do not hesitate to contact us.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Milling - steels and metals - Import exportNumber of results

5 ProductsCompany type

Category