- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high pressure hydraulics

Results for

High pressure hydraulics - Import export

KW HYDRAULIK GMBH

Germany

Brochure High Pressure Washer Metropolis Hydraulic driven high pressure washer for connecting at an hydraulic circuit. water pressure max. 210 bar For cleaning in areas without infra structure ( no electric ) Water pump with three ceramic pistons Hydraulic engine group 2 (6ccm) Adjustable water pressure Perfect for built-in solutions at concrete transport trucks, tractors, street-cleaning trucks or concrete pumps Low noise - low maintenance - low vibrations For cleaning machines at the construction Suction lift max. 5 meters Water connection: 3/8“ Max. water temperature: 50°C optional for chemicals and pesticides Water-Bypass-system Optioanal: Elektric ON/OFF true integrated 12 Volt solenoid valve. This version has an Oil-Bypass. Type Water Output Spin Power Oil Input Weight WHY-1520 15 L/min. @ 210 bar 1750 rpm 5,5 kW 15-40 L/min. @ 210 bar 8-9 kg THY-2715 27 L/min. @ 150 bar 1750 rpm 5,5 kW 15-40 L/min. @ 210 bar 10-11 kg The METROPOLIS unit is a professional...

Request for a quote

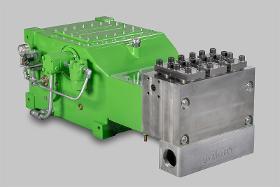

KAMAT GMBH & CO. KG

Germany

K25000-3G high-pressure triplex plunger pump for 24/7 operation, pipeline tensioning and leak testing of tanks and various pipelines. The K25000-3G is used internationally hundreds of times as a high-pressure pump in hydraulic face construction. With a power of 250 kW, a gearbox with forced lubrication and an optional oil cooler, the pump is perfectly suited to the demands of 24/7 mining operations. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod load - Dynamically balanced gearbox - Forced lubrication gearbox (> 160 kW with oil cooler) - Standard gear ratios i = 3.33 - 3.50 - 4.04 - 4.62 - 5.44 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

SDT ULTRASOUND SOLUTIONS

Belgium

Non-rotating asset components seldom receive the routine surveillance they need Hydraulic systems represent another way industry converts electricity to mechanical energy. A pump, normally powered by an electric motor, moves hydraulic fluid through a system. The system is typically made up of a reservoir to hold the hydraulic fluid, high pressure lines to carry the fluid, control valves that ensure the fluid is sent where needed, relief valves for safety, and cylinders to produce mechanical energy. The pump and motor receive attention while the balance of the system is run-to-failure. Ultrasound testing could change this lackadaisical approach; especially considering its versatility, ease of use, and applicability to most hydraulic defects. External and Internal Leaks External leaks can often be found by visual inspection. Some external leaks, like a ruptured hose or fitting, are easy to spot. Simply follow the trail of spilled oil. Others are not so obvious.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes is a leading supplier of aerospace hydraulic tubes where they are deployed in the airframes and engines of both commercial and military aircraft. Our thin wall tubes are used to actuate flight control surfaces that bear heavy aerodynamic loads such as flaps and slats. They are also crucial components in aircraft landing gear and brake systems. Trusted by Major Airframe Manufacturers Fine Tubes is one of only a handful of tube mills worldwide qualified to produce the titanium tubing used for the 5,000psi high-pressure hydraulic systems of the Airbus family. Titanium provides a weight saving of 42% compared to the equivalent quantity of traditional stainless steel tubing. Please note that we have a minimum order value of £10,000.

Request for a quote

IPR GMBH

Germany

Safety cutting unit consisting of: Hydraulic power unit cube Integrated pressure gauge up to 1000 bar 10m High pressure hydraulic hose (metal free ), firmy connected to the cutting head Superlight cutting head ipr50HS Remote Control 3m Power charger 3m User manual Tool case The total weight of our 95 securty system weights about 17 KG and not 30 KG!

Request for a quote

NITTO KOHKI EUROPE GMBH

Germany

Generic Cupla copes with high pressure lines in hydraulic equipment! Low pressure loss is ideal for hydraulic equipment. Complys with international standard ISO 72411A. General purpose hydraulic Cuplas with the working pressure up to 27.5~31.5MPa {281~321kgf/cm2}. Structure keeps pressure loss extremely low, particularly ideal for hydraulic applications requiring high flow rates. Both socket and plug have builtin automatic shutoff valves to prevent fluid spill out when disconnected. Easy to handle. Special steel body material is adopted for its excellent strength and additional quenching treatment is done to withstand hydro pressure impacts. Various end configurations.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The portable HD 2500 is designed for delivering high hydraulic pressure up to 2500 bar required for operating hydraulic tools, especially hydraulic tools for loosening and tightening the clamping connections provided at large diesel engines. Capacity hydraulic pressure up to 2500 bar. Drive medium Compressed air with at least 6 bar. Features The hydraulic pressure is adjustable up to 1500 bar. Up to four hydraulic tools can be supplied simultaneously.

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The portable HD 1500 is designed for delivering high hydraulic pressure up to 1500 bar required for operating hydraulic tools, especially hydraulic tools for loosening and tightening the clamping connections provided at large diesel engines. Capacity hydraulic pressure up to 1500 bar. Drive medium Compressed air with at least 6 bar. Features The hydraulic pressure is adjustable up to 1500 bar. Up to four hydraulic tools can be supplied simultaneously.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp hydroforming presses are used for the production of complex and intricate workpiece shapes. This complexity relates to both longitudinal and cross sections. Next to large batch production in the automotive industry, the tting industry is one of the numerous application areas for this type of press. Compared to conventional forming methods, the forming possibilities are signicantly increased when forming with high pressure. Features hydraulic clamping forces: < 100 MN high pressure intensier: < 10.000 bar axial forces / axial cylinder: < 5 MN short cycle times due to "quick lling" systems Advantages weight savings of 40 to 50 %, in some cases up to 75 % wall thickness distribution optimized to component requirements high work-hardening continuous material grain ow for optimum component performance high dimensional accuracy

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Excellent board qualities are only achieved when the endless particle mat is degassed and compacted before being transferred to the ContiRoll®. This is realised by the Siempelkamp prepress for particleboard production. Features, function An air evacuation zone, the angles and levels of which are adjustable. High-pressure zone incl. hydraulic position control Two circulating belts Belt cleaning systems incl. extraction system installed along all the belts Advantages Eective prevention of soiling or material jams No belt indents in the board surfaces Variants, options Endless air evacuation belt

Request for a quote

ULBRICH GMBH

Germany

Mobile Puller with 100 to press force with integrated acetylene-compressed air ring burner or high pressure hydraulic power pack. The solution with integrated acetylene-compressed air ring-burner is specially developped for wheel-disk without oil-pressure-drilling. While the solution with the high pressure-hydraulic power pack is put into action on wheel-disks with oil-pressure-drilling. It is also possible to have a puller with both solution combined.

MESA MAKINA DOKUM GIDA SAN. TIC. A.S.

Turkey

We offer a wide range of high pressure filtration solutions to meet with your fluid power transmission system requirements. Hydraulic High Pressure Inline Filters (450Bar) Models : Mt450-040 ,063 ,100 ,160 ,250 ,400 Pressure line filters are installed on the hydraulic system line and ensure that the used oil is constantly filtered / cleaned. Usage Areas are ; Industrial Hydraulic Mobile Hydraulic Earthmoving & Mining Hydraulic Marine Hydraulic Open-sea Hydraulic Space Hydraulic

Request for a quote

MESA MAKINA DOKUM GIDA SAN. TIC. A.S.

Turkey

MS 450 MESA DIN 24550 Hydraulic pressure inline filters according to Up to 450bar (6526psi),are manufactured under international standards & regulations in comply with ISO TS 16949, EFQM 4*, ISO 14001, OHSAS 18001.The filter ratings are 5-25 microns. We offer you a wide range of ultimate high pressure filtration solutions for Industrial Hydraulics,Mobile Hydraulics,Marine Hydraulic,Open-Sea Hydraulics, Aviation Hydraulics,Space Hydraulics to meet your system requirements perfectly. Mesa Makine A.S. is one of the industry Pioneer factory & exporter who is engaged in Casting & Machining technology. We have many professional collaborations with leading USA & EU business partners at our business scope.

Request for a quote

GTIP GRUP DIS TIC. LTD.

Turkey

NUMBER MIPT pieceDescription (MIPT) ProductsPRESSUREfunctionalityCOLORMEASUREDTemperature G03131160001STEEL WIRE FOUR FLOORS4SP / EN 856Black3/8 " G03131160002STEEL WIRE FOUR FLOORS4SP / EN 856Black1/2 " G03131160003STEEL WIRE FOUR FLOORS4SP / EN 856Black5/8 "

Request for a quote

EKOMAXI MODULAR WATER STORAGE SOLUTIONS

Turkey

Modular panels of water tanks and water conservation tanks are manufactured on high-pressure hydraulic molding presses under-regulated high temperatures from GRP or SMC (glass fiber reinforced polyester resin.) Application of regulated heat and pressure make GRP or SMC structure very strong and rigid. Manufactured according to the world-renowned WRAS and EN 13280: 2001 quality management system. GRP Modular Water Tanks ceilings, floors and sides surfaces are all made of hot pressing. This highly qualified engineering product is the best and most preferred among water storage. • Very long life • Low weight • Resistant to corrosion • No electrical conductivity • Low thermal conductivity • Has dimensional stabilizers • Resistant to UV rays • Hygienic according to all other tanks. • can be processed in a simple way • No recycling • Paint or maintenance-free • Can be manufactured in any color • Not magnetic • Light transmittance can be provided • Chemical and combus

Request for a quote

NORM FLEXIBLE PIPE COMPANY

Turkey

Exhaust semi-flexible pipe is making double layer curls so this product have ability to semi-flexibility and non-flammable. It has sealing capability so water and gas can pass through. This product can be use; generators, automotive, trucks, caravans, marine vessels exhaust systems and protect for high-pressure hydraulic hoses. This pipe type is double-clamped and semi-flexible. We can produce galvanized, stainless steel or tin plate by special kind order. Type of Manufacturing: Galvanized, tin plate or stainless steel Diameter Range : 25 mm - 150 mm Nominal Tickness : 0.20 mm - 0.40 mm

KASAG SWISS AG

Switzerland

We are your experts in design, engineering, and manufacturing of welded versions of high-pressure apparatuses, high-pressure autoclaves and plants. With comprehensive non-destructive testing methods, such as X-rays of the welding seams or pressure testing of up to 1000 bar, we ensure smooth product quality. With KASAG products, you can withstand pressure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

For special applications, individual high-pressure systems are required, which KAMAT can provide from the initial project idea to the turnkey installation, with 100% of the production taking place in-house. This also applies to electric high-pressure pumping units. Depending on the application, our customers can choose between different drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation equipment. Even the electrical units supplied on the base frame are fully operational and can be used directly by the customer. Electric units have the advantage of emission-free operation at extremely low noise levels. ATEX certified high pressure electric units can also be used in ATEX hazardous areas.

Request for a quote

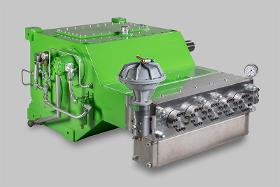

KAMAT GMBH & CO. KG

Germany

With a maximum drive power of 1000 kW, the K100000-5G high pressure pump is an extremely powerful pump. As a five-cylinder pump (quintuplex), it offers the possibility of pumping without inlet pressure in many applications. Its special five-cylinder design allows high flow rates without cavitation in the pump. Like its smaller counterpart, the K55000-5G, it is used for larger jetting or hydraulic applications. Special Features Flow rate based on 100% volumetric efficiency and 20°C ambient temperature Min. inlet pressure dependent on fluid Speed range 10-100% depending on rod force dynamically balanced gear Gear unit with forced lubrication and oil cooling gear ratios i = 3.40 - 4.10 - 4.69 - 5.19 - 6.03 Also available to API 674, including vertical operation Filtration up to 350 µm Special media such as seawater, glycol, methanol, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

customer-specific unit design incl. powerful high-pressure pump easy maintenance cavitation-free central drainage according to the latest global emission laws optionally fully automatic control own software with best support optional extreme sound absorption optionally all explosion protection classes

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

POPPE + POTTHOFF MASCHINENBAU GMBH

Germany

Autofrettage is a method for increasing fatigue strength of components for use at high and pulsating pressures. In short, Autofrettage compresses a container’s inner surface, making better use of the material’s structural properties. The process can reduce fatigue concerns in pulsating applications and lets engineers reduce tubing thickness in high-pressure applications without sacrificing strength, life, or safety. The autofrettage method is based on the reciprocal relationship of the plasticized inner zone and the elastically deformed outer zone. The components are placed under so much pressure that their interiors become plastically deformed. After relaxing, pressure stresses are created in these areas, which prevent the outer areas from reforming to their original shape. Instead, it remains stretched. This prevents crack formation in the later application, increases the service life of

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

BALTECH OTOMOTIV SANAYI VE TICARET LIMITED SIRKETI

Turkey

The function of a Pressure Switch is to provide a path for an electrical circuit that is triggered at a certain pressure. Example uses are: •Oil pressure warning light in an automobile •Pump controller (turn well pump on and off) •Air compressor control •Industrial process signaling A pressure switch must have a process connection (usually threaded for a pipe or tube) and an electrical contact that is connected to wires or terminals. They may sense rising or falling pressure and most are adjustable, so the contact will engage (or turn on the electrical circuit) at a desired pressure setting. They can be pneumatic (air and gases) or hydraulic (water, oil or fluids) or even strictly mechanical. The internals can be a diaphragm capsule, a small chamber backed by a spring or a bourdon tube. The contact is usually copper points but can also be a mercury (in glass) tip switch. Unlike Pressure Transducers which give an analog electrical signal proportional to the amount of pressure, these

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Bend 90° F/F

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Reducer

Request for a quote

SANHA GMBH & CO. KG

Germany

In air conditioning and refrigeration technology, particularly in commercial and industrial refrigeration systems, environmentally friendly solutions are becoming more and more important. Optimum results are been obtained by an increase in efficiency and the use of ecologically safe refrigerants such as CO2 (R744), which are mainly used in the transcritical part with higher operating pressures. However, the use of CO2 leads to higher operating pressures potentially up to 130 bar. SANHA Ref HP fittings are specifically designed for such operating pressures. They are ideally suited for pipes in refrigeration systems with a maximum operating pressure of up to 130 bar (other pressures on request), a minimum temperature of -196 ° C and a maximum temperature of 150 °C for fluids in Group 2 according to European Pressure Equipment Directive (PED 97 / 23 / EC). Coupling

Request for a quoteResults for

High pressure hydraulics - Import exportNumber of results

43 ProductsCompany type

Category

- Connectors, plumbing (10)

- High-pressure cleaning machines (4)

- Pumps (4)

- Construction - Machines & Equipment (2)

- Gear pumps (2)

- Piston pumps (2)

- Aerospace and aeronautics - construction (1)

- Assemblies, hydraulic (1)

- Autoclaves (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Coupling, pneumatic (1)

- Electric and electronic components - machines for manufacturing (1)

- Exhaust systems, vehicle (1)

- Finished Metal Products (1)

- Foundries - machinery and installations (1)

- Mechanical transmission - components (1)

- Monitoring and control equipment (1)

- Oil filters (1)

- Presses, hydraulic (1)

- Steels, nickel (1)