- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- hot forming

Results for

Hot forming - Import export

KEBA FASTENINGS

Germany

Diameter range of M 12 - M 80 with lengths reaching up to 800 mm. Tailored manufacturing according to specific standards, drawings, and samples. KEBA Fasteners can be coated according to your requirements such as galvanized, phosphatized, or hard chrome plated. Chrome VI free coatings for the automotive industry (e.g. Geomet Plus, Delta-Protect) is also available. Reduced-shaft bolts, pan head screws, square head bolts, fit-bolts, hexagon head bolts, hexagon socket head cap screws, wheel bolts, bearing bolts, threaded bolts, clevis pins with head and many more which can be tailored to customer specifications according to the model or drawing and many more which can be tailored to customer specifications according to the model or drawing.

Request for a quote

KALELILER CIVATA SAN VE TIC A.S / FASTENERS

Turkey

Kaleliler is manufacturing steel bolts from vaious types within a range of M 12 - M 72 . Heat Treatment, Surface Treatments and quality control lab are all INHOUSE. Kaleliler is an expert in hot forging and special fasteners production. ISO 4014,4017,4762,10642; EN 14399-4, EN 15048; Oval bolts, Eye Bolts, Hammer Bolts are some of the products that are produced often. All quality checks are done in our inhouse laboratory and 3.1 B certificates acc. to EN 10204 standard is maintained. Our products is traceable for years by the help f our ERP System.

Request for a quote

ROBINSON CO.

Turkey

Counterflow cooler is utilized for cooling the feed that comes out from pellet mill in pellet form which is hot, to ambient temperature. It works according to steady air form principle. Air in the external environment contacts the feed in the cooler; while the temperature of the feed drops, warm air is removed from the environment through air aspiration system.Discharge system which is on the cooler, removes cooled feed. Drainage system can be chosen with grid or hydraulic valve depending on the preferred product. Drainage system is adjustable and works according to the capacity. Applications Fields ◾ Feed Plants

Request for a quote

KEBA FASTENINGS

Germany

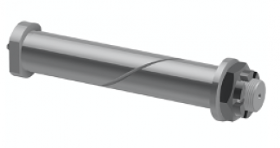

are threaded bolts suitable for the automotive industry and heavy earth moving equipment. Able to endure heavy impact loads Uniformed case hardness to ensure strength and flexibility Precisely manufactured to fit perfectly on spring bushes

Request for a quote

KEBA FASTENINGS

Germany

are bolts hot forged from all common materials including stainless, acid resistant and heatproof (inductive hardening, case hardening, quenched and tempered) steel. Diameter range of M 12 - M 80 with lengths reaching up to 800 mm. Tailored manufacturing according to specific standards, drawings and samples.

Request for a quote

CMPLAST

Poland

It is characterized by good susceptibility to machining. It is very susceptible to hot forming and forging. It is widely used in the production of forged parts with complicated shapes parts for pipe fittings industrial terminals heating elements plumbing industrial fittings We also have other nonferrous materials on sale.

Request for a quote

KMD CONNECTORS STOLBERG GMBH

Germany

CuNi3Si alloy with very good bendability, very good hot and cold forming properties, a high strength and a good corrosion resistance. Perfect material for Connectors, bent parts, relays.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

The round tubes are manufactured from a coil that is bent and electric resistance welded (ERW). The forming process can be according to EN 10210, which foresees hot forming or cold forming followed by heat treatment, or according to EN 10219, which foresees cold forming without following heat treatments. The finished product is fully killed and welding seam bead is inside and outside trimmed. These products are used to manufacture both welded and bolted structures, in the field of constructions, engineering, industrial constructions, transports, automotive, agricultural machinery and earth moving machinery. The cold finished tubes are particularly suitable for structures at sight or for aesthetical uses, thanks to the surface aspect typical of cold forming. NORMS HOT FINISHED” TUBES EN 10210-1/2 COLD FINISHED” TUBES EN 10219-1/2 INSIDE TRIMMING EN 10217

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

In 2015 the product name was changed. The old product name was Castrol Optimol Paste PL. Black assembly paste with MoS2 Description Castrol Molub-Alloy Paste PL (previous product name Castrol Optimol Paste PL) is particularly suitable for pressure-loaded sliding points as well as base and thin film lubrication at high pressures and temperatures. For larger areas and in hard-to-reach places such as bores, threads and sprockets, the use of Castrol Molub-Alloy Paste PL Spray is recommended . Application Castrol Molub-Alloy Paste PL can be used for screw connections, snug and press fits at high temperatures up to +600 °C, on plain bearings, bushings and gears, on drive trains in the automotive industry, for basic lubrication of bed tracks, guides and joints as well as for clean Separation of tool and workpiece during hot forming of metals.

Request for a quote

DRESSLER GROUP

Germany

We developed a special process for making fine powder systems and composites from low-viscosity melts. With the patented cryo-spraying process CSP, it has become possible to produce highly sensitive products directly from a hot melt to form a solid powder without after-cooling. The entire spraying process is overlaid with nitrogen and also protects very critical substances against oxidation and thermal stress.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of temperature-stressed machine parts, e.g. rolling bearings, friction bearings, slideways, chains, rollers or moving parts in hot forming, heat treatment or drying Dry lubrication, e.g. of kiln and rack-truck bearings, bearings of pouring ladles, converters or hot-air blowers at temperatures over 250°C Lubrication of plastic and rubber at normal temperature when the materials concerned are not resistant to mineral oil Advantages and benefits Highly effective due to the strong affinity of the MoS₂ for metals Extremely low friction at highest loading capability Broad range of applications at temperatures up to 200°C as paste, over 200°C to 450°C as dry lubricant Resistant to water, fuels and lubricants, chemicals and hydraulic fluids For best adhesion, clean the threads and sliding surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS 2610 or OKS 2611 universal cleaner.

Request for a quote

MEBA STEEL & INDUSTRIAL SUPPLIES TRADE GMBH

Germany

Production standards are summarized as below for Cold Formed Sections; Water and gas pipes: EN 10217-1 TR1, EN 10255, DIN 2440, BS 1187, ISO 65, N FA49-145, ASTM A53, ASTM A500, DIN 2999-2986, BS 1387, ASTM A53 Industrial Pipes: DIN 2458-1615 & 1626, BS 6363, BS 6323, BS 1139, EN 39, EN 10219-2 Open Sections: EN 10162 Square and Rectangular HS: EN 10219-2, DIN 2395, DIN 59411, BS 6363, N FA49-541, ASTM A500, UNE 36-537, SI 1458 For Hot Formed Sections as per EN 10210/ASTM A501.

Request for a quote

BIEGLO GMBH

Germany

BIEGLO offers polyimide powders for various processes. The Dexnyl PI powder is available in two different particle sizes. Our Dexnyl PI Powder 100P_19 suitable for compounding and compression molding application and our Dexnyl PI Powder 260_19 is suitable for producing compression molded and direct formed parts. The range of products that can be produced from our polyimide (PI) is only limited by the processing machines. Polyimide powder can be processed by hot compression molding, direct forming, iso-static compression molding or it can be compounded with other materials as an additive. Polyimide powder is often compounded with PTFE to increase certain properties of the PTFE.

Request for a quote

ANTHERMO GMBH

Germany

Efficient use of waste heat (up to 1.000 °C) In many production processes waste heat occurs in form of hot air which is put out to the environment without any use. Very often these hot gases are contaminated air. On the other side clean (cold) air must be warmed up for the production process. In these cases cross flow heat exchanger can reduce the energy costs. The hot air stream will be conducted in the cross or counter flow method over the cold air inside the cross flow heat exchanger. Though both air streams are strictly separated because of the construction of the heat exchanger and they don´t get mixed (leakage less than 0,5 %). Only the energy of the hot waste stream is transferred to the cold clean stream.

Request for a quote

HAGO BAUTECHNIK GMBH

Austria

Material: Steel-plate cover, frame made of cold formed sections. Hot-dip galvanised. With hinge. Cover can be removed from the open position. Covered hasp locking device (padlock not included). Ventilation pipe (Ø 10 cm) fitted with cowl and insect-excluding mesh. Sealed with hollow chamber seal. Applications: For individual wells, spring water catchments, high-level tanks etc. Total height including ventilation cylinder ≈ 30 cm. *S = available from stock *O = to order

Request for a quote

NECRON ENERGY ELECTRONIC SAN. TIC. A.S.

Turkey

"The NECRON RM series is one the best performing and most reliable three phase hot-swappable modular UPS system for a wide range of applications such as Security systems, Financial services, Server/Data centers, Industrial environments, etc.. The capacity is easily augmentable for Modular technology so RM series is able to grow according to necessity of the system. It has unique isolated air flow structure for hot-swappable power modules (being formed of IGBT modules) to get higher performance and reliability of critical situations. It is scalable from 30kVA to 900kVA with N+X modular architecture/parallel topology. RM series saves your energy thanks to self-aging function without connecting real loads during test procedure. Monitoring and managing RM series with the largest size of colorful touch screen that provides graphical and text based information for safer operation. All UPS system are fully supported by NECRON service team that assures reliable, preventive and corrective miss

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg as a experienced Steel Parts CNC turning source factory customized many steel parts according to customer's designs, quality always good and price lower than others. We have many different type turning machines, automatic turning machines, and CNC turning machines,Swiss CNC turning lathe, Turn & Mill Composite machining Machine, 3,4,5 axis CNC machining centers. We also equiped cold forging & hot forming production line, can produce blanks for our steel turned parts, greatly reduce the material cost, improve the processing speed and cost, improve the quality of the workpiece. According to quantity & precision requirement, optimize the turning processes to make the machining cost to be lowest. We produce turned parts from raw materials of bars,tubes,forged blanks,casting.,According to the number of parts, structure and other factors, choose the most economical and reliable blanks.saving cost improve quality.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom CNC lathe turning parts with Low Price and High Quality ! Ming Xiao Mfg as a experienced Steel Parts CNC turning source factory customized many steel parts according to customer's designs, quality always good and price lower than others. We have many different type turning machines, automatic turning machines, and CNC turning machines,Swiss CNC turning lathe, Turn & Mill Composite machining Machine, 3,4,5 axis CNC machining centers. We also equiped cold forging & hot forming production line, can produce blanks for our steel turned parts, greatly reduce the material cost, improve the processing speed and cost, improve the quality of the workpiece. According to quantity & precision requirement, optimize the turning processes to make the machining cost to be lowest. We produce turned parts from raw materials of bars,tubes,forged blanks,casting.,According to the number of parts, structure and other factors, choose the most economical and reliable blanks.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specializes in plastic extruding both Rigid and Flexible PVC Profiles and PVC tubing. Finished PVC Extrusions can be fabricated into more complex assembly by hot bending, forming, notching, punching, gluing, riveting and other techniques. We are able to produce almost any component suitable for flexible or rigid PVC extrusion processes. If you have special requirements, we invite you to discuss with us. We are focus on plastic extrusion custom services for worldwide customers, and have produced more than Thousands of plastic profiles & pipes for foreign clients in the past 15 years. At the same time, we have gained a wealth of experience, and the requirements for product quality have further deepened our understanding. Plastic extrusion products mainly use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services.

Request for a quote

PLANSEE SE

Austria

Metallic hot zones are made for very high temperatures between 1000 °C (1 832°F) and 2 800 °C (5 072 °F). As a specialist in refractory metals Plansee delivers molybdenum and tungsten hot zones with an excellent form stability and lifetime. Plansee designs and produces hot zones for various types of furnaces (vacuum, protective gas atmosphere, HIP etc) and thermal processes such as sintering, brazing or annealing. Hot zones consist of countless individual parts such as heating elements, shield packs and hearth assemblies and charge carriers. You can find all of these components at Plansee. - Hot zones made from molybdenum, tungsten, tantalum, niobium and their alloys - Full metal or hybrid hot zones with graphite or ceramic fiber insulation - From very small (a few cm³) through to very large (several m³) hot zones - For temperatures of between 1000°C (1832°F) and 2800°C (5072°F) - Tailor-made design: round, rectangular, vertical, horizontal or special geometries

Request for a quote

BIZERBA SE & CO. KG

Germany

Ideal for commercial meat production environments The FW-N 32/98 Heavy Duty Commercial Meat Mincer minces raw, cooked or smoked meat. Even marbled meat – in hot or cold form – bacon, offal, rind and vegetables can be minced. For us, mincing means commutation or controlled processing of meat instead of squashing it. FW-N 32/98 Heavy Duty Commercial Meat Mincer produces a loose and fluffy volume. The mixture retains its red colour due to increased oxygen enrichment. Food processing facilities will achieve perfect results and the machines can be cleaned quickly and efficiently. With a throughput of up to 1100 kg/h, the FW-N 32/98 Heavy Duty Commercial Meat Mincer is the right solution for preparation rooms, large kitchens or as a manual solution for production. Fast and precise mincemeat production with an impressive output per hour. Some exciting features of the Heavy Duty Commercial Meat Mincer are as follows, Clearance-free fit for gentle commutation without warming up and...

Request for a quote

BIZERBA SE & CO. KG

Germany

Compact commercial meat mincer for sales counter and preparation area The Carneoline FW N22/82 commercial meat mincer, minces raw, cooked or smoked meat. Even marbled meat – in hot or cold form – bacon, offal, rind and vegetables can be minced. Food processing facilities will achieve perfect results and the machines can be cleaned quickly and efficiently. This heavy duty meat mincer is one of the favourites amongst butchers globally. The robust and easy clean design are not the only benefits to this fantastic piece of machinery. The Bizerba commercial meat mincers incorporate unique technology with a gentle cutting process due to the unique worm solution. Gently mincing the meat as oppose to forcing and and stretching the product. This is how you get the perfect mince every time. Even though the cutting process is gentle, it can still produce up to 350 kilograms of mince per hour. A completely solid stainless steel constructed commercial meat mincer with seamless welding. No...

Request for a quote

KLN ULTRASCHALL AG

Germany

The riveting process creates irresolvable interlocking bonds. This is achieved by forming or reforming of thermoplastics. In most cases in this procedure only point-shaped or segmented joints are realized. In contrast to welding of two components there cannot be achieved hermetic joints. A particular version of this procedure is the bonding of plastics with metals, textiles and cardboard. The method is frequently used for wooden decoration parts, into which a chrome decoration strip has to be embedded. As a rule the hot form riveting is carried out in a one-cycle process. A heated riveting stamp forms the riveting head under pressure. After forming the stamp is shortly cooled down in order to avoid adhesion of the plastic material on the thermal riveting stamp. After this short cooling phase the riveting stamp is again moved above.

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic HM 75 boasts an outstanding concept and is the ideal hotformer for the costefficient production of complex forgings with a diameter of up to 180 mm and an initial weight of up to 7.5 kg. Main advantages Integrated HFE functionality for forwards extruded forgings, Versatile machine kinematics for complex applications, Servohydraulic end stop system for optimal cutoff quality, Lowimpact part discharge reduces the need for remachining, High process reliability thanks to accurate transfer unit with individually monitored grippers

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quote

HATEBUR UMFORMMASCHINEN AG

Switzerland

The HOTmatic AMP 70 is the ideal hotformer for the costefficient production of forgings with a diameter of up to 165 mm, with a production rate of up to 80 parts per minute. Main advantages Wide range of uses, Intuitive operation, Triedandtested, efficient cooling system for maximum tool service life, High availability due to short retooling times, High material efficiency thanks to servoinfeed and electronic bar end elimination device (ESA 600)

Request for a quoteResults for

Hot forming - Import exportNumber of results

47 ProductsCountries

Company type

Category

- Thermoforming, plastics - machinery (12)

- Connectors, electronic (3)

- Brass (2)

- Butchery - machinery and equipment (2)

- Turning - steels and metals (2)

- Additives for plastics industry (1)

- Bottles and jars, glass (1)

- Cements, special (1)

- Chemical catalysts (1)

- Construction - Machines & Equipment (1)

- Copper and copper alloys (1)

- Electric transformers, converters and rectifiers (1)

- Extrusion of rubber and plastic (1)

- Fasteners, metal (1)

- Flour milling - machinery and equipment (1)

- Forming - steels and metals (1)

- Glass hollowware, coloured (1)

- Glass hollowware, lighting (1)

- Heat exchangers (1)

- Heat treatment furnaces (1)