- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- inductive heat treatment

Results for

Inductive heat treatment - Import export

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Inductively heated vacuum heat treatment furnaces with high operating temperatures specially for the manufacture of hard materials. Standardized components for a broad application spectrum and useful space volumes from 34 to 338 litres. Applications: IOV furnaces are used for all high temperature processes and serve for sintering and heat treatment processes such as degassification, graphitizing, destillation, impregnating, infiltration, reducing and carburization. Benefits for users: An extremely robust type of system, especially appropriate for processes where dust incidence or high temperatures are involved.

Request for a quote

ERATEC

France

Tissue drying Lamination Ironing Heat treatment rollers

Request for a quote

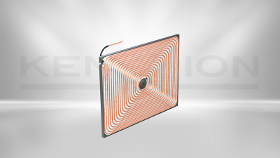

KENDRION KUHNKE AUTOMATION GMBH

Germany

Surface mount inductors are used for heating processes in the food industry, in packaging machines or in embossing processes in the graphics industry. The material thickness of the heated tools can be reduced due to the surface energy input. This increases the dynamics of the process and saves energy.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

Roller inductors are used in the production of synthetic fibres or in embossing processes in the graphics industry. Different roll diameters can be applied and one or more axial heating zones can be realised depending on the requirements. An essential advantage of the roller inductors is the contactless energy transfer to the rotating roller. ; Roller inductors from 60mm diameter; No slip rings required; Divided into independently controllable axial segments; Optimal temperature control & uniform heating; Emission-free heating

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The controller is a fieldbus device for the control of up to 7 power modules from the modular heating System from Kendrion, which are directly connected via the module bus. In addition to system monitoring, the controller can also control or regulate the individual output channels of all power modules. Actual temperature values can be delivered directly via CAN fieldbus or provided by a higher-level controller e.g. a PLC. ; PROFINET Fieldbus interface; Independent control of up to 7 induction generators; System monitoring, temperature control; Integrated I/Os and CAN system bus

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The induction generator is designed to supply up to 4 induction coils (inductors) with a power of up to 7.5 kW each. The device operates on the three-phase mains with a voltage of up to 400 V and a frequency of 50/60 Hz. The mains current is rectified and fed to the DC link, from which the inductors are individually supplied.

Request for a quote

KENDRION KUHNKE AUTOMATION GMBH

Germany

The induction generator module is designed to supply up to 6 induction coils (inductors) with a power of up to 3 kW each. The device operates on the three-phase mains with a voltage of up to 400 V and a frequency of 50/60 Hz. The mains current is rectified and fed to the DC link, from which the inductors are individually supplied. The output power is controlled via the Kendrion controller of the modular industrial heating system. The setting range from 0% to 100% can be selected individually for each channel. By using state-of-the-art semiconductor switches, the output stages achieve high efficiencies, at working frequencies up to 25 kHz.

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

Our high frequency converters are providing frequencies of up to 2 MHz at up to 200 kW output. For lower frequencies down to 4 kHz we have our mid range frequency converter series MU.

Request for a quote

HIMMELWERK HOCH- UND MITTELFREQUENZANLAGEN GMBH

Germany

Our Inductors are individually crafted for your exact production process. This ensures point perfect delivery and is maximing the energy efficiency of your heating process.

Request for a quote

EXTRA FORGE D.O.O.

Slovenia

At our company, we offer comprehensive heat treatment services for both steel and aluminum products. Our team consists of expert associates who are leaders in their respective fields, ensuring top-notch quality and precision in every project. Additionally, we provide valuable consultation to help you determine the best available options or optimize processes to achieve your desired results efficiently.

Request for a quote

FRIGORTEC GMBH

Germany

Using the DEBUGGER method (heat treatment) from FrigorTec, the DEBUGGER DB18 has proven its effectiveness in killing insects, larva, and eggs, for decades. This method increases the air temperature to a range between 45°C and 60°C, and keeps it there, so that pests die off without using chemical substances, thus preventing damage to buildings and their fittings. A power distributor is required depending on the size of the installation site or the number of devices, and we recommend using one or more SCRAMBLER SC 6000s to save energy. Fields of application > Specially developed for large spaces, e.g., mills, bakeries, the food-processing industry > Often used in spice and coffee processing, as well as in the tobacco industry, muesli manufacture, and small animal feed production > Combine several DEBUGGER DB18s in very large rooms and halls

Request for a quote

M.E.G.A. SPA

Italy

M.E.G.A.’s forging and heattreatment division is capable of forging fittings (in a closed die) up to 4” 16 kg. The heat treatment furnaces and tanks are all certified to Norsok M650 and ASTM A991 standards and can treat any product that M.E.G.A. produces (large and small forgings, pipes and any other type of part).

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

With the new PICO-S series, eldec presents an extremely compact mobile generator. Depending on the model, it can be configured as a medium frequency energy source (5 up to 30 kW) or high frequency energy source (5 up to 15 kW). Induction heating with maximum PICO efficiency The compact PICO-S, perfect for portable use, is based on proven technology from German induction heating specialist eldec, while the configuration of its central elements has been simplified and distilled down to the essentials – resulting in not only lower construction costs but also a lower price to the customer. Operation of the PICO-S couldn't be easier, yet the mobile generator is still capable of processing a very wide range of materials and workpieces with high power density. All you need to do is unpack it, plug it in, and start heating!

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

PICO-M: mobile generator for perfect induction heating Induction generators of the PICO-M series are standardized and consequently cost-effective – without any compromise in quality. The device is available in a medium-frequency version (50 and 75 kW) and a high-frequency version (25 and 35 kW). High power density for induction heating Specially designed eldec control, proven inverter technology, and an intuitive operating interface – the advantages of eldec's compact PICO-M induction generators are of direct benefit to any user. All in all, this is a simple yet very powerful induction generator based on standardized components – and that is what makes its costs of investment so low.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

The name “CUSTOM” already says it all: HF generators of this series are configured precisely for the relevant production task. Their HF power ranges from 100 to 1,500 kW. The frequency range is 80 to 400 kHz. Induction generators with high power density On this basis, numerous combinations of power and frequency are possible – a key prerequisite for effective induction heating. eldec induction generators also provide high-precision energy dosing, which guarantees the reproducibility of the process. In addition, CUSTOM LINE HF generators are available with a comprehensive bundle of options: Offers include hose bundles of various lengths, a Profibus interface, pyrometer-based temperature control, as well as a cable box with a heating cable for shrink applications.

Request for a quote

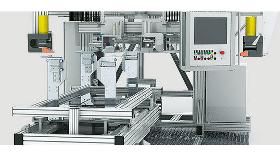

EMAG ELDEC INDUCTION GMBH

Germany

eldec brazing systems: automatic induction brazing of pole coils The semi-automatic equipment is designed for manufacturing pole coils of hydro and wind power generators. The machine is based on the experience of the previous manufactured equipments. The machine is designed as a sturdy, high quality and low maintenance machine. The operating is very simple, on automatic mode by 2-hand operation with step by step program and on manual mode by touch-panel.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Energy source and coolant system — the MICO-S is a complete system in a single housing. This enables a flexible integration of induction heating into any production process. The devices are available in a medium frequency and a high frequency version. The specialists at eldec are using the MICO-S generators for the induction heating and hardening of components with a very flexible process. The key factor is the innovative design concept of placing the generator itself and the cooling system in a single housing. As a result, the unit takes up very little space and is quick to set up. The unit weighs a mere 390 kg and is easy to move around. It has openings in the base plate to allow for pick-up with a forklift, as well as crane hooks. As a result, users benefit from an extremely efficient and flexible energy source for induction heating and hardening.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EMAG ELDEC INDUCTION GMBH

Germany

The eldec MICO-L generator offers users a particularly powerful complete solution that includes a coolant system. Medium (18 to 80 kW) and high-frequency devices (15 to 35 kW) are available. High-performance complete solution for cost-effective induction heating The L in the name of these induction heating systems stands for “large”. In the medium-frequency version, the MICO-L delivers up to 80 kW for hardening and heating parts and components. This powerhouse comes with a generator, cooling system, controller, and hose bundle. It can be moved on casters as an option (a base plate for stationary use is always included) and is therefore available at all times. Inside, carefully selected high-performance components ensure safe and precise heating processes. The reliability and efficiency of these devices is the result of decades of development and optimization by eldec.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

eldec is well-known for its SDF® technology – patented dual-frequency generators which can be operated simultaneously or separately with medium and high frequency. Although SDF® generators are suitable for users looking for a generator with a switchable frequency, but do not want simultaneous frequency, they are often too expensive. We can now supply DF generators (dual-frequency generators) for these applications: switchable dual-frequency generators with the product and service quality you expect from eldec.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

To achieve perfect induction heating processes depends on generators providing precisely the right amount of energy. With its CUSTOM LINE LF generators, eldec provides just the right solution for the low frequency range (2 to 8 kHz). Induction heating with tough generators “Customized” is the key word when it comes to delivering a perfect production solution in mechanical and systems engineering. This is particularly true for induction heating. The process needs to be configured accurately to produce the desired effect in the material. CUSTOM LINE generators by eldec are the ideal solution for delivering precisely the right amount of power and energy. The LF series (power: 50 to 500 kW, frequency: 2 to 8 kHz) is designed for lower frequencies.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Efficient, rugged, and flexible – eldec CUSTOM LINE MF generators offer state-of-the-art medium-frequency technology perfectly matched to your requirements. Their MF power ranges from 200 to 1,500 kW. The frequency range is 8 to 40 kHz. Induction heating with a comprehensive set of options Customized energy sources are the key for effective induction heating or hardening of parts. A made-to-measure solution ensures stable production processes and low energy consumption. CUSTOM LINE MF medium-frequency generators by eldec provide exactly these kinds of qualities. The configuration options are virtually unlimited. In addition to a wide range of power and frequencies, users have the choice between solutions with single and multiple outputs. As a result, several inductors can be connected to the compact CUSTOM LINE MF generator via separate hoses.

Request for a quote

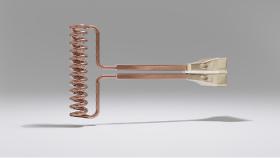

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

Inductor design and manufacture continues to be one of eldec’s core competences. The inductor forms the foundation of every eldec induction machine. Every inductor is specifically made-to-order for a workpiece. The basis of this is the frequency, material and power density which means that precisely that area of the workpiece is heated that should be heated. eldec heating cables are used for the heating of large components. The form of the inductor and its design are tailored to the geometry of the workpiece area it is to heat. An inductor from eldec is designed using the very latest 3-D CAD solid modelling software, manufactured on CNC machine tools and built by trained personnel with excellent training at eldec in Germany and the USA. This means that every inductor is made to measure, precise and highly accurate.

Request for a quote

EMAG ELDEC INDUCTION GMBH

Germany

nduction Heating and Joining in one turnkey system. This turnkey system is used to heat electric motor housings with various dimensions for a wide range of joining processes. Example Heating System 1: the die-cast aluminium housing for an asynchronous motor (diameter 450 mm) is heated to approx. 290°C in approx. 5 minutes to fit the wound stator package. The parts are loaded and unloaded from the feeding belt parallel to the working time. The heating process takes place in two independent work stations. The generator has a switched output which means that only one generator is required for the two heating stations. The system is controlled using a SIEMENS PLC controller. Example Heating System 2: the aluminium housing (diameter 140 mm) of a synchronous motor is heated to approx. 280°C in approx. 3 minutes to fit the stator. The component is loaded into and unloaded from the heating station semiautomatically. The system is controlled using a PLC.

Request for a quote

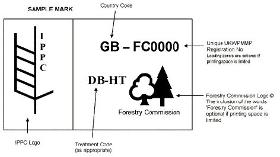

PLASTIC PALLETS UK / ASSOCIATED PALLETS LTD

United Kingdom

ISPM15 is an international standard for phytosanitary measures which is being progressively implemented throughout the world. Already some 28 countries have adopted the standard; a further 21 are in the progress of doing so and about another hundred countries have signalled their intension to bring the requirement to their national regulations. Countries which have signed up to ispm-15 are entitled to refuse entry at their frontiers to goods on wooden pallets, crates, spools or any other wood packaging unless it has been treated, marked and certified in accordance with their regulations. Associated Pallets Ltd has been providing a heat treatment which meets the demands of ISPM-15 and since the introduction of the plant some four years ago, has become experienced in all needs of the wood packaging producer and user.

Request for a quote

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Dimensions up to 600x600x900 mm, weight up to 800 kg. LPC (vacuum cementation) option. Hardening, heating in a gas environment and isothermal cooling.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Our range of products includes welded charging aids such as guide grids, charge carriers, tempering baskets, traverses, basket inserts, wire mesh baskets, charging baskets, heat-resistant workpiece carriers, as well as hardening boxes for the heat treatment of steel or other metals. good strength properties at high temperatures Continuous operation in air up to approx. 1150 ° C with temperature changes up to approx. 1000 ° C perfectly suitable for heat treatment We use according to customer requirements .EN 1.4845 / AISI 310S .EN 1.4841 / AISI 314 Both materials are heat-resistant steel. Due to the higher chromium and nickel content and have a good resistance to oxidation. The good strength properties are still present even at higher temperatures. Both also have excellent chemical resistance up to 1100°C.

Request for a quote

NERI MAKINA MÜHENDISLIK SANAYI VE TICARET LTD. ŞTI.

Turkey

Workpiece carriers guarantee safe workpiece handling - especially when it comes to reliably protecting sensitive workpieces from damage during transport and cleaning. We develop and produce workpiece carriers for high-precision and sensitive components. This means that the components are carefully embedded and positioned in customer-specific automation magazines in such a way that they are easily accessible for a gripper. In addition to being used with manual handling, the workpiece carriers are particularly suitable for customers with a high degree of automation. The tailor-made solutions are mainly used in production with automatic parts removal and in the material flow of the automotive supplier industry.

Request for a quoteResults for

Inductive heat treatment - Import exportNumber of results

29 ProductsCompany type