- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- loading unloading

Results for

Loading unloading - Import export

FERPLAST SNC

Italy

Lifting platform HY 1001 pantograph with low profile. Also included in the price is the access ramp of 1200 mm length, for the discharge and the load by pallet truck. Features: Structure in high thickness sheet steel with high thickness Construction according to European safety standards Electrohydraulic control unit positioned externally Keypad with protection IP 54 positioned on the hydraulic power pack Security perimeter aluminum on the upper platform Hydraulic power unit designed for intermittent use by 30%. Keypad with low voltage controls Hydraulic system with a safety valve for overload Control valve for descent speed Large hydraulic cylinders with valve fall arrest in case of breakage of the pipes Joints with self-lubricating bushings Lifting hooks removable for transportation and installation Mechanical lock for maintenance Painting with yellow RAL 1028 Access ramp length 1200 mm for pallet truck

Request for a quote

MIX SRL

Italy

Pressure / Vacuum control valves suitable for safeguarding containers during loading / unloading phases of powder, grain and fibre products

Request for a quote

FERPLAST SNC

Italy

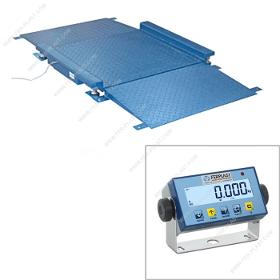

FLOOR SCALES WITH LOADING RAMPS FPL SERIES WITH LOW PROFILE - INDICATOR EXCLUDED Low profile platforms, with embossed steel frame and ramps in painted steel. They are suitable for weighing trolleys and pallet trucks as they are equipped with loading/unloading ramps and side rails on the weighing platform. Available in standard or CE-M approved version TECHNICAL FEATURES - Operation with 4 350 Ohm shear-beam load cells in nickel-plated steel, approved according to OIML R60 C3 standards (3000 divisions), IP67 protection degree. - Structure and loading surface embossed in steel, oven painted, RAL 5007 blue color. - Adjustable anti-shock adjustable feet and level bubble. - Power supply from 5 to 15 Vdc. - Hermetic junction box, IP67 wiring with 5m shielded cable for connection to the indicator. - Side rails and double ramp up/down, standard.

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

FERPLAST SNC

Italy

COMPLETELY AUTOMATIC STRAPPING MACHINE MOD. JN85-M Fully automatic strapping machine with high speed and reliability. The machine is equipped with motorized belts for insertion in packaging lines, aluminum arc with multiple flaps to facilitate the launch of the strap and the subsequent release and electrical system with Omron PLC. The electrical panel of the machine can manage the motorized loading and unloading belts (optional) and allows the use of the strapping machine in lines without operator.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GL MARINE SURVEYORS S.R.L.S.

Italy

An effective step to avoid the shortage claim is to arrange a tally survey of the cargo. This means checking or keeping a record of the cargo loaded into or discharged from a vessel

Request for a quote

TECNO AZZURRA S.R.L.

Italy

Details Product storage tank, internal paneling made of aisi 304 stainless steel Coating of internal paneling with teflon to facilitate the falling of product and subsequent internal cleaning High efficiency polypropylene pneumatic pump Pneumatic pump compressed air pressure control device Double aisi 304 stainless steel filter to safeguard efficiency of pneumatic pump Internal ramps complete with nozzles suitable for achieving an optimum impregnation of the part to be treated Internal fittings to load/unload product impregnating machine Product drip collection tray with replenishment in machine

Request for a quote

M SERVICES SRL

Italy

The gear hobbing machine, model DM 4.0, is a CNC machine designed for the machining of small and medium gears and endless screws. The rigid structure and the high quality materials ensure high production standard, allowing longer duration of cutting tool. The strength of the machine DM 4.0 is the simplicity of machine tooling combined with the high versatility to adapt to the equipment of the customer. Gear hobbing machine can be furnished with an optional customizable loading/unloading system. The software is simple, complete and intuitive and it can be adapted or implemented on specific requests. Gear hobbing machine DM 4.0 is suitable for remote assistance, installable on request.

Request for a quote

M SERVICES SRL

Italy

Our centring-facing machines are designed to meet the request of higher flexibility, precision and simplification of small and large production end-machining , combining great power and high rigidity and also allowing to integrate an automatic loading / unloading system.The base is an electro-welded and normalized steel structure and it has been specially designed with directional slides to convey chips into the specific integrated conveyor; the underlying ribs are arranged in such a way as to be able to absorb any vibration.The use of a touch screen operator panel with easy programming ensures versatility and simplicity of application, making simultaneous machining possible on both ends.Two opposite working units are used, each moved on CN work axes (axis “Z1” and “Z2”) frontal to the piece, whereas the Self-centering clamps with oleodynamic control are moved by a third controlled CNC axis (X axis) for the management of the drilling / centering tool center as well as for millin

Request for a quote

TAMA AERNOVA SRL

Italy

Model with pallet swap Data sheet The cutting shuttle table used to support the metal sheet must be integrated into the laser and plasma cutting machine. It is equipped with a drive system that follows the laser head to focus the suction of fumes and dust in the sectors affected by the cut. Its installation ensures the quality of the production environment and the protection of those who work there. Benefits This model with automatic pallet swap is composed of two sliding pallets driven by a chain drive, a hydraulically driven external lifting unit that allows vertical pallet change from a air suction segment table with trimming collection drawers which can be extracted from the side. The laser cutting downdraft table is interfaced with automatic load/unload cells and it is composed of pre-assembled modules, easy and quick to install. Standard equipment tanks with suction segments plate support grid leveling feet position sensors

Request for a quoteResults for

Loading unloading - Import exportNumber of results

11 ProductsCountries

Company type