- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- knurling

Results for

Knurling - Import export

UNIFY THREAD ROLLING

Taiwan R.O.C.

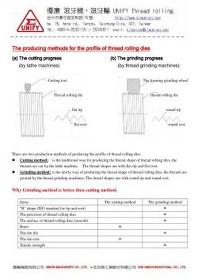

Specification: There are 2 producion methods of producing the proflie of thread rolling dies: Cutting method: is the traditional way for producing the thread shape of thread rolling dies, the threads are cut by the lathe machine. The thread shapes are with flat tip and flat root. Grinding method: is the newly way of producing the thread shape of thread rolling dies, the threads are ground by the thread grinding machines, teh trhead shapes are with round tip and round root. Why we choose the grinding method for UNIFY thread rolling dies, please check the above for the reason. Currently, we have more then 10 units of REISHAUER thread grinding machines (Swiss made) in our factory. The thread rolling dies offered by UNIFY are always the grinding type. The higher level quality can be ensured!

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

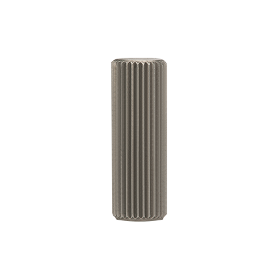

In respect of rolling the serration type working pieces as the transmission shafts of autobobile/motor-vehicles, spline shaft, and manual tools. The grinding type serration spline rolling dies can be ensured for the precision, delicate and smooth surface, extending the life of the rollers.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

For the mass production of fastener screws, it may also another good choice for the flat type thread rolling which may reduce production cost, applied to big-valume production. With the same named tool steel SKD11 (JIS) and SKH9, together with advanced heat treatment technology, and thread grinding CNC machien to offer the customer for another choice.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

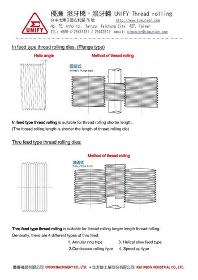

In feed (Plunge) thread rolling dies: There are multiple starts (helix angle) at the edge of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling of shorter length. the thread rolling progress as: Place a work piece in between of thread rolling dies, the screws are formed by strongly pressing progress, when the right thread rollign die returns, take out the work piece. (the work piece stays at the same rollng point). Thru feed thread rolling dies: The threads are as the rings on the surface of thread rolling dies. The type of thread rolling dies are sutiable to thread rolling longer length of screws. (longer then the length of thread rolling dies) The threading progress as: Set the helix angle with the roller shafts of thread rolling machines first, and insert the thread rolling dies. 1. Place a work piece in between of thread rolling dies, make sure the work piece is clamped by thread rolling dies. 2. The work piece is moving

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

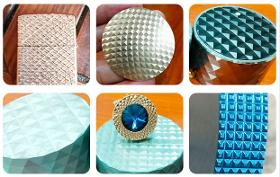

The knurling die: The knurling pattern with non-skid and attracting in appearance on manual tools (straight knurling pattern or diamond knurling pattern) by the knurling dies. The knurling pattern is formed by gear hobbing machine before the heat treatment process, the precision is less good as the grinding type, but, the straightness, and concertricity can be assured.

Request for a quote

UNIFY THREAD ROLLING

Taiwan R.O.C.

The superior tool steel is a very important element of thread rolling dies. SKD11 (JIS) and 1.2379 (DIN) are the named raw material which we have chosen for the past years. The blank of thread rollingd ies are heat treated by Japanese TECHNO vaccum & oil quenching furnace by heat treating dep. (TOYOGEN INDUSTRIAL CO.,) It will render the higher rigidity and higher wear-resistance of thread rolling dies. After the heat tratment progress, the thread rolling dies are ground by Swiss REISHAUER thread grinding machines. And another progress of tempering to reduce the grinding stress is necessary for thread rolling dies. The thread rolling dies are ready for sale after the quality exam. The good quality of thread rolling dies is able to offer higher precision, longer working life, and reduced the cost to customers. We also produce the thread rollingd ies for other brands thread rolling machines. Your special specifications and requirements are very welcomed.

Request for a quote

SPIROL

Germany

SPIROL's FH200 Headed Straight Knurled Pin has the same body style as the KP200 Straight Knurled Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH200 Headed Straight Knurled Pins have a flat head, however they are available to order with a round head (RH200) to meet specific application requirements. Similar to the SPIROL Series KP200 Straight Knurled Pin offering, SPIROL's Series FH200 Headed Straight Knurled Pins are available in metric diameters ranging from Ø2.5mm to Ø6mm and inch diameters ranging from Ø.094" (3/32) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's KP200 Straight Knurled Pins have straight knurls that span the full length of the pin. Straight Knurled Pins are commonly used in applications where the pin is subjected to rotational forces to transmit torque as well as to resist rotational movement of a mating component. KP200 Straight Knurled Pins are available in metric diameters ranging from 2.5mm to 6mm and in inch diameters ranging from .094" (3/32) to .250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's Knurled Pins are manufactured with two different knurl types: straight knurls and helical knurls. Unlike a Straight Pin, where retention is provided by the uniform interference between the pin and hole, Knurled Pins are designed to cut into the host. The displacement of the host material into the valleys of the knurls yields more frictional contact area between the Knurled Pin and hole; thus resulting in higher retention. Solid Pins with retention features such as knurls and barbs allow for wider hole tolerances than Solid Pins without retention features (i.e. Straight Pins).

Request for a quote

HONSEL-GROUP

Germany

The knurled shaft of the blind rivet nut provides a locking device to avoid the turning of the insert in the component. These knurled blind rivet nuts are used preferably in components with lower regidity (component material is less "hard" than the material of the blind rivet nut).They are available with different heads (dome, countersunk and small countersunk) and as open and closed end versions.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Brass Parts Custom Service, Produce Knurled Brass Nuts & Screws Manufacturer custom high precision brass turned parts & machined parts according to customer's drawing or samples, Dimension accuracy and surface can be well guaranteed! Name: Brass Parts Turned & Machined Material: Copper,Brass Finish: Natural,Tin plating,nickel plating, etc Machined type: Automatic Lathe Turning, CNC Turning, Knurling, Milling & Drilling Compound Tool Machinings China Ming Xiao Mfg (mxmparts.com) Custom brass parts for world customers, we are professional brass parts supplier. Welcome to contact with me for discussing your brass/ copper parts.

Request for a quote

ACTON S.A.

France

S = Assembling capacity X = Thinner flush head

Request for a quote

ACTON S.A.

France

Knurled Nuts Low Type (ECR Low Knurled) Stainless Steel A1 - DIN 467

Request for a quote

ACTON S.A.

France

Knurled Nuts High Type (ECR Knurled high) A1 stainless steel - DIN 466

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the parts made by brass, then after colorful plating, the products mainly used in electronic product field.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the products used in fashion decoration products.The material are aluminum alloy,zinc alloy and brass and so on...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts.

Request for a quote

SPIROL

Germany

You can rely on SPIROL to be a design partner to help solve unique problems. Because we supply numerous customers with similar products in similar industries, we are able to meet most needs with our standard products at no additional cost. When the solution falls outside the normal requirements, we have the expertise and engineering personnel to solve those problems. By working with you at the design stage, we will develop a solution that lowers your overall product cost, improves product quality, increases the robustness of your manufacturing process, and gets you to market faster.

Request for a quote

SPIROL

Germany

Series RH600 Twist-Lok™ Pins replace costly screw machined pins and eliminate problematic installation of screws and rivets. The helical knurl minimises stress during installation by rotating as it engages the hinge. Corrosion-resistant material and a rounded burr-free head improve installed appearance. Axial and radial forces induced in the hinge eliminate the tendency for the pin to creep and maintain hinge tension.

Request for a quote

SPIROL

Germany

SPIROL designs and manufactures specific types of Solid Pins to meet the performance and assembly requirements of common niche applications. These Solid Pins are variations of our standard product either manufactured from specific material, have a specific finish or undergo specific processing to meet performance, corrosion, compatibility and assembly requirements for the specific application. These pre-designed application-specific series of Solid Pins help companies shorten the design cycle to confidently launch their product quickly to the market with a pinning solution that has been tested and proven within their assembly.

Request for a quote

SPIROL

Germany

SPIROL's FH300 Headed Helical Knurled Pin has the same body style as the KP300 Helical Knurled Pin, with the addition of a head. A Headed Pin is typically used to provide a positive stop or to retain a thin component to a thicker component within an assembly. FH300 Headed Helical Knurled Pins have a flat head, however they are available to order with a round head (RH300) to meet specific application requirements. Similar to the SPIROL Series KP300 Helical Knurled Pin offering, SPIROL's FH300 Headed Helical Knurled Pins are available in metric diameters ranging from Ø2mm to Ø6mm and inch diameters ranging from Ø.078" (5/64) to Ø.250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

SPIROL

Germany

SPIROL's KP300 Helical Knurled Pins have helical knurls that span the full length of the pin. The 30° helical knurls cause the pin to rotate during installation into the hole. Helical Knurled Pins offer higher insertion and retention than Straight Knurled Pins. However, KP300 Helical Knurled Pins are not typically recommended when the pin will be subjected to rotational forces as the helical knurl will cause the pin to either "unscrew" itself from the hole or further imbed itself into the hole. KP300 Helical Knurled Pins are available in metric diameters ranging from 2mm to 6mm and in inch diameters ranging from .078" (5/64) to .250" (1/4) in low carbon steel and austenitic stainless steel.

Request for a quote

JÄGER & FRESE GMBH

Germany

knurled nut made of stainless steel made by turning M8x15

Request for a quote

SIKO GMBH

Germany

Premium knurled aluminum handwheel. Compact design. Various sizes. Surface plastic-coated, anodized or bright-finished. Various hub versions.

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Delivery program: Plastic Screws From M3 x 20 mm to M10 x 60 mm. Plastic Knurled screws DIN 653 from M3. Plastic Transverse-hole screws DIN 404 from M3 x 20 mm. Plastic Nuts From M3 Plastic Threaded pins DIN 551 from M3 Connection elements Other connection elements such as discs, caps, spacers and diverse articles moulded from all commercially available plastics (granulate). All articles are available with the specifications listed next. Materials: Articles moulded from PA, POM and all other plastics (granulate) commonly available on the market. Standards: According to DIN/EN/ISO or drawings. Colour: According to RAL table or individual customer wishes.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China CNC Turned Parts Manufacturer custom produce all kinds of turned parts according to customer's drawing or samples, we can produces stainless steel Turned parts,carbon steel Turned parts, aluminum turned parts,brass & copper turned parts. Specialize in producing stainless steel motor shaft eccentric shaft knurled shaft precision parts China If you are interest in our CNC machining services, please feel free to send inquiry to us, and then our professional sales manager will get back to you ASAP! sales@mxmparts.com WhatsApp +86 13780014913

Request for a quoteResults for

Knurling - Import exportNumber of results

33 ProductsCountries

Company type

Category

- Screw cutting - steels and metals (8)

- Screws (8)

- Fastening devices (3)

- Electric and electronic components - machines for manufacturing (2)

- Automation - systems and equipment (1)

- Construction - Machines & Equipment (1)

- ELECTRIC EQUIPMENT (1)

- Electric motors and parts (1)

- Light fixtures, decorative (1)

- Machine tools, metal machining - parts and accessories (1)

- Nuts and bolts (1)

- Nuts and bolts, custom-made (1)