- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- aircraft engines

Results for

Aircraft engines - Import export

ROTAFILO

Turkey

For each tool, we keep records including Drawings, CMM/AMM, TTE Equivalency Determination Checklist, Material Certs, Inspection Recording Sheets, Test Reports, Certificate of Equivalency.

Request for a quote

ROTAFILO

Turkey

Engine tooling plays a vital role in the development, production, maintenance and overhaul of aircraft engines. It is often very simple in itself. The challenge lies in the interface to the engine, understanding the sequence, the complexity of the program and the volume of quantity. Here where ROTAFILO team comes for clarification and guidance.

Request for a quote

ROTAFILO

Turkey

Rotafilo engine stands perfectly suit your operational needs and your budget targets. Stands can be used for removal/installation and transportation.

Request for a quote

IMM MASCHINENBAU GMBH

Germany

CNC machine tool with 6 axis for belt grinding, polishing and belt linishing aircraft engine airfoils such as fan blades, vanes (OGVs and IGVs), steam turbine blades and gas turbine compressor blades and vanes. Extreme high precision and repeatable stock removal allows balancing of milling process to save milling time and cutter costs by maximizing milling roughness followed by MTS process.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA can improve material proportion and complete solution according to industry demand to achieve the best effect of customer use. Boron Nitride Ceramic Rod Characteristics: High thermal conductivity, pressed into various forms, used as high temperature, high pressure, insulation, heat dissipation components, such as aircraft, rocket engine nozzles. 2. Excellent thermal shock resistance and erosion resistance. It is used in Amorphous Ribbon Making and amorphous nozzles, three-dimensional printing metal powder diversion tubes, nozzles, etc. 3. High strength non-sticking, applied to various hot-pressing dies.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

Major engineering companies who design and manufacture aerospace engines rely on the strength and durability of tubing products made at the Superior Tube mill. This is due to our reputation for producing high quality, high strength, yet lightweight tubing. You’ll find our tubes at work within a variety of systems in aircraft including fuel delivery, fire suppression, drain lines and bleed air systems. Bleed air is high temperature, high pressure air taken from the jet engine and fed into various areas of the plane to be used for things like de-icing and cabin pressurization. We use high performance materials such as Alloy 321 stainless steel and Inconel 625 and 718 for applications that deal with extreme temperatures. Precision tubing for aerospace engines can be ordered in sizes from 0.250” outside diameter right up to 1.5”. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

We deliver precision tubes specially engineered for aerospace engines that perform in the most extreme pressures and temperatures. Trusted by Major Engine OEMs Our aerospace engine tubes are trusted by major OEMs to operate in a variety of critical aircraft engine systems including fuel delivery, fire suppression, thrust reverser, drain lines, and bleed air systems. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloy 718 was initially developed for the aerospace industry but its excellent strength and corrosion resistance were recognised by the oil industry and it is now widely used in this field also. Alloy 718 is a nickel-chromium alloy with additions of niobium & molybdenum which can be heat-treated to give high strength, good corrosion resistance, ease of formability and which can be welded with good resistance to strain age cracking. The alloy can be used at temperatures up to 700ºC. Alloy 718 for the oil industry is heat treated such that the hardness does not exceed 40HRC which is the maximum allowed by NACE MR-01-75/ ISO 15156: 3 to prevent stress corrosion cracking. Alloy 718 for aerospace and power generation is heat treated to give maximum strength and high creep resistance with typical hardness values exceeding 42HRC. The major applications are components for gas turbines, aircraft engines Please note that we have a minimum order value of £10,000.

Request for a quote

STROJHIMTREJD

Russia

General description EPOKUKDO YD-128 is a standard type liquid epoxy resin derived from Bisphenol-A. It has excellent adhesion, chemical resistance, heat resistance, etc. Due to its special properties, YD-128 is generally used in many areas. YD-128 is the most standard liquid resin Epoxy resin KER-828 is used in the electrical, radio-electronic industry, aircraft, shipbuilding and mechanical engineering, in construction as a component of casting and impregnating compounds, adhesives, sealants, binders for reinforced plastics.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Our isothermal forging presses produce sophisticated, heavy-duty components for high-tech products. We furnish our customers with rst-class solutions including control systems for the ne-tuning of pressing speeds. Our presses are designed for high-precision applications indispensable in the aircraft/aerospace and medical engineering industries. The challenge here is to manage pressing speeds of 0.01 mm/s in controlled operation, which is ensured by our own electrical and hydraulic control engineering Siempelkamp also oers plants to be used for isothermal forging. They comprise the furnace, the feed manipulator, the forging press, the die heater, the hydraulic drive system and the entire automation technology. The plant control for isothermal forging presses monitors and documents the process parameters in compliance with the certication standards to be observed in the aircraft industry.

Request for a quote

HERACLE GMBH

Germany

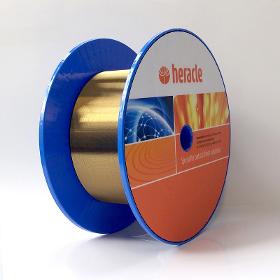

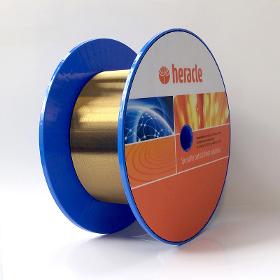

Our aluminum coated fiber are available for both operating windows in ultraviolett and visible/near infrared wavelength ranges. In addition, heracle offers a solarisation resistant version for ultraviolett region. The fiber features a wide operating temperature range from cryogenic up to 400° C and makes it ideal for Aircraft, missile, rocket, turbine & jet engine monitoring. The aluminum layer offers a hermetic coating. The fiber can be sterialized. Termination can be directly soldered for vacuum feedthroughs & laser diode pigtailing. Its radiation resistancy, low outgassing and resistancy to organic solvents allow for operation in radiation, caustic & corrosive environments.

Request for a quote

HERACLE GMBH

Germany

heracle developes and produces specialty optical fiber with metal coating for application in harsh environments. Fiber types include Mutimode fiber with step or graded index profiles and Singlemode fiber. All fiber fiber types can be offered with either Gold or Aluminum coating. The pure fused silica step index multimode fibers (SIMM) are optimised for applications in the UV/VIS and VIS/IR wavelengths. The graded index Multimode fiber is designed to operate at 850nm and 1300nm. The Singlemode fiber is specified accoring to according ITU-T G.652. Metal coated optical fibers are typically used under extreme conditions such as: - Aircraft, missile, rocket, turbine & jet engine monitoring; - Radiation, caustic & corrosive environments - Material fatigue sensing applications - High power laser delivery systems - Ultra high vacuum applications

Request for a quote

HERACLE GMBH

Germany

Our gold coated fiber is available for both wavelength ranges: from UV, VIS up to infrared wavelength ranges. The fiber offers excellent protection against chemical corrosion & mechanical stres and is capable of withstanding extreme temperatures and harsh environments. The fiber can be terminated directly onto the coating for hermetically sealed assembly. Our Gold coated fiber has very low outgassing of volatile components. We perform 100% stringend test procedures according to international standards. Typical applications are typically for extreme conditions such as: • Aircraft, missile, rocket, turbine & jet engine monitoring • Radiation, caustic & corrosive environments • Material fatigue sensing applications • High power laser delivery systems • Ultra high vacuum applications

Request for a quote

FREE FIELD TECHNOLOGIES - MSC SOFTWARE BELGIUM

Belgium

Actran TM A powerful acoustic CAE tool for turbomachinery noise prediction Actran TM is the reference CAE tool for analyzing the sound radiated by turbo machines and for optimizing the related acoustic treatments. Actran TM is used extensively by many leading aerospace companies that rely on the tools’ accuracy, ease-of-use and performance for reaching their strategic acoustic design goals. Actran TM contains all advanced modeling features required for turbo machinery noise analysis. To capture the important convection and refraction effects, the sound waves propagate on top of a non-uniform background mean flow which can be calculated by Actran or imported from a CFD simulation. The influence of the mean flow on the performance of acoustic liners is accounted for thanks to the Myers boundary condition. The acoustic source is defined in terms of incident duct modes of arbitrary order and their amplitude can be defined in a variety of ways (e.g. normalized amplitude, intensity, equal distribution of energy on all propagating modes) or derived from pressure fluctuations calculated on a set of planes by one of the supported CFD tools. Both 3D and axisymmetric models can be defined. One of the challenges of acoustic CAE is to handle large models associated to high wave number and to large geometrical size and complexity. Actran TM meets this challenge thanks to its efficient solver technology that includes advanced parallel processing. Actran TM is used not only for optimal aircraft engine nacelle liner design but also on inlet and outlet liners for helicopter turbines, environmental control systems (ECS) or auxiliary power unit (APU). Actran TM is also used for non aerospace applications like computer cooling system noise and more. Actran TM can be complemented by Actran DGM to solve problems involving complex shear layers and flow gradients occurring at the engine exhaust. Model courtesy of Alenia Aermacchi™ Target Applications: Aircraft engine noise, including nacelle design Ducted cooling systems (electronic devices) Blower systems (air conditioning modules) Helicopter turbine noise

Request for a quote

HEXCEL COMPOSITES LIMITED

United Kingdom

Resins and resin-impregnated reinforcements for high strength, toughness and structural performance at low weight. Hexcel provides a range of prepregs under the HexPly® trademark for aerospace and industrial applications, using specially formulated epoxy, phenolic and BMI resin matrix systems. HexPly® prepregs are reinforced with woven, multiaxial and unidirectional (UD) carbon and glass fibers. The aerospace industry is the greatest consumer of Hexcel prepregs, for civil aircraft, military jets, helicopters, aero-engines or space satellite and launchers. Hexcel’s range of resin formulations for aerospace prepregs includes a wide range of epoxies for highly loaded parts and supreme toughness; BMI systems for high temperature performance; phenolics for fire, smoke and toxicity performance in aircraft interiors; and cyanate esters for space structures and satellite applications. ** Click for more **

Request for a quoteResults for

Aircraft engines - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Aircraft engines (3)

- Optical fibres (3)

- Pipes and tubes, stainless steel (2)

- Ceramics, industrial (1)

- Chemicals - Basic Products & Derivatives (1)

- Chemicals - import-export (1)

- Forming - steels and metals (1)

- Machine tools, metal machining - parts and accessories (1)

- Polishing - machine tools (1)

- Steels, nickel (1)

- Technical textiles (1)