- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- ceramics

Results for

Ceramics - Import export

THERMA THERMOFÜHLER GMBH

Germany

Use: Connectors for thermocouples and resistance thermometer measurement circuits. Suitable for measurement with small wires and mineral-insulated metal sheathed cables. Mechanical design: • Ceramic housing with contacts of original thermocouple materials and spring-loaded sockets for reliable contact . • Reverse polarity protection by different contact pin widths. • Oversize screw head for easy wiring. • One-piece housing withstands great stresses. • Housing of high purity alumina oxide.

Request for a quote

NORELEM FRANCE

France

Exceptionally wearresistant Dimensionally stable even at high temperatures Electrically insulating Frequency neutral

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

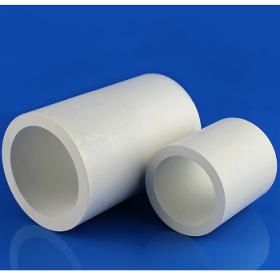

INNOVACERA® Hot Press Boron Nitride Rod Diameter 32 mm, two length in stock (25 mm, 100 mm), custom length is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride High thermal conductivity Low thermal expansion Good thermal shock resistance High electrical resistance Low dielectric constant and loss tangent Microwave transparency Non toxic Easily machined — non abrasive and lubricious Chemically inert Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron Nitride Specifications: >Outside Diameter: 6.40 mm >Inside Diameter: 1.70 mm >Wall Thickness: 2.35 mm >Length: 100 mm >Condition: Hot Pressed >Custom size is available. White in color. Hexagonal Boron Nitride has a microstructure similar to that of Graphite. In both materials, this structure, made up of layers of tiny platelets, is responsible for excellent machinability and low-friction properties. we called hexagonal boron nitride (HBN) or white graphite. Features of Boron Nitride: 1.High thermal conductivity 2.Low thermal expansion 3.Good thermal shock resistance 4.High electrical resistance 5.Low dielectric constant and loss tangent 6.Microwave transparency 7.Non toxic 8.Easily machined — non abrasive and lubricious 9.Chemically inert 10.Not wet by most molten metals

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

No other oxide ceramic material collectively exhibits these highly desirable properties and characteristics. BeO ceramic conducts heat more quickly than virtually all metals with the exception of copper and silver. Beryllia exhibits extremely low dielectric loss characteristics, possesses high electrical resistivity, and offers excellent strength with high specific stiffness properties. BeO provides all the desirable physical and dielectric characteristics exhibited by an aluminum oxide or aluminum nitride, in addition, offers thermal conductivity ten times higher than alumina, and fifty percent higher than aluminum nitride, a dielectric constant that is lower than both alumina and aluminum nitride, and weight per given volume that is fully a quarter less than alumina, and nearly ten percent less than aluminum nitride. As a thermally conductive and electrically insulating material, its performance is exceeded only by that of the diamond.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA® PBN ceramic part includes the PBN Disc, PBN Sheet, PBN Filament Ring, PBN VGF Crucibles, PBN LEC Crucibles, PBN MBE Crucibles, PBN Conical Crucible, and Other PBN Machined Custom Parts. Molecular beam epitaxy (MBE) is a standard process for gallium GaAs crystal production, and PBN is the ideal material to make MBE crucibles. INNOVACERA® Performance Pyrolytic boron nitride properties are as below: Good thermal conductivity High insulation resistance High dielectric strength over wide temperature ranges Extremely pure Non-wetting Non-toxic Non-reactive to most other compounds Withstand high temperatures and rapid cooling

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater Chip for Automobile / Oxygen Sensor

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater for Automobile / Oxygen Sensor

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Planar ceramic heater oxygen sensors are subject to extreme conditions. A properly functioning oxygen sensor forms the basis for reliable engine operation and thus fuel economy, low pollutant emissions, and good exhaust gas values. Oxygen sensors with planar ceramic heater characteristics: ● Quick ignition time ● Good insulation performance ● Strong resistance to high temperature and poisoning ● Long lifetime ● Pump current switch type, conventional switch type, air-fuel ration type, and wide range type are available Appliaction: Plate Ceramic Heater for Automobile / Oxygen Senser

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Electric 12V 13V Alumina Ceramic Heating Element Heater Rod for Oxygen Sensor Advantages Ceramic Heater for Oxygen senster is used for heating oxygen sensors that detect the exhaust gas of vehicles and is equipped to most of automobile gasoline engines. Because the temperature can be rapidly raised, it is possible to activate the sensor immediately after the engine start which provides useful feedback to reduce emissions. 1.Based material: a.white alumina ceramic b.the content of alumina is no less than 95%. c.the tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C 2.Ni-wires:N6 Ni-wires with 0.6mm diameter 3.Brazing material: siliver-copper braging alloy

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Heater for Soldering iron & Station: Alumina Ceramic Heaters are produced by implementing unique metallization and ceramic lamination processes. Due to the advanced manufacturing techniques utilized in the electric element, Alumina Heaters can provide higher reliability than ever before.Currently, applications include use as innovative types of heaters in the automotive, medical and semiconductor industries. a.Based material: white alumina ceramic, and the content of alumina is no less than 95%.The tungsten slurry is printed on the ceramic tape, laminated by hot pressing, and thensintered under the protection of a hydrogen atmosphere at 1650 ° C b.Ni-wires:N6 Ni-wires with 0.6mm diameter c.Brazing material: siliver-copper braging alloy Application: We are producing High Quality 24V 110V 220V Heating Element for Soldering Station with the advantages of energy-efficient,long lifetime,high insulation,super fast heatin up and eco-friendly.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Pellet Igniter Information Ceramic Boiler Ignition Igniter surface can reach a permanent working temperature above 900℃;Since air can through and around inside and outside of the heater tube. Heat can be transferred from both inside and outside of ther heater element. Igniting wood chips, firewood, coal bricks or other biomass fuel. Specification: Voltage: 120V / 230V Power: 150W / 170W / 200W / 230W Tube Size: OD10.5 × ID6.5 × L78 mm Supporting Socket: NO.7 Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) Range of temperature: 800~1100 °C Alumina Pellet Igniter Advantages 1) Higher temperature, about twice of traditional metal sheathed heater; 2) Shorter ignition time, about 60~90 seconds 3) Electrically insulated with no exposed electric contacts 4) Wear and corrosion resistance 5) Long life time 6) Easy to install and replace 7) Long-lasting (non-aging). Tested to 100,000 cycles. 8) 800~1100°C at steady-state temperature.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Black Coating Type 220V 230V 240V Alumina Pellet Ceramic Igniter Alumina Ceramic Hor Surface Igniter can reach a permanent working temperature above 1000℃;Since air can through and around inside and outside of the heater tube. Heat can be transferred from both inside and outside of ther heater element. Igniting wood chips, firewood, coal bricks or other biomass fuel. > Dimension: 106*11.5mm (Or Customized) > Voltage: 230V > Power: 270W - 315W > Lead wire: 300mm / 400mm / 500mm / 900mm (Customized is accept) > Range of temperature: 800~1000°C > Electrode: Welding leads on the electrode FEATURES: 1、Black coating type 2、300W+5%-10% 3、60-90 seconds ignition time 4、Available in 120V 220V-240V 5、ROHS/REACH certification 6、Many design available 7、Customized welcome

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

INNOVACERA Alumina Ceramic hot surface igniters for pellet boilers only need approx. 1/10 of the energy needed by hot air fans and ignition blowers.Their ignition capacity lies between 120 and 350 W. Depending on the positioning of the ignition element in the boiler, the ignition time of approx. 60 seconds is extremely short. This also means minimal emissions. Alumina Ceramic Heater Specification: > Voltage: 120V/230V > Power: 160W, 180W, 210W, 225W, 230W, 240W, 255W > Tube Size: OD10.5 × ID6.5 × L90 mm > Supporting Socket: NO.4/NO.5/NO.6/NO.29 > Lead wire: 300mm/400mm/500mm/900mm (Customized is accept) > Range of temperature: 800~1100 °C Ceramic igniter technology benefits: * A fraction of the energy consumption compared to element heater. * Long-lasting (non-aging). * Time to ignition 60~90 seconds. * Tested to 100,000 cycles. * Easy to install and retrofit. * 800~1100°C at steady-state temperature. * Impervious to oxidation and corrosion.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

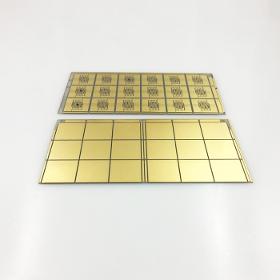

DPC (Direct Plated Copper) Mainly by evaporation,magnetron sputtering and other surface deposition process to carry on the substrate surface metallization,first under the condition of vacuum sputtering,titanium,and then is copper particles,the plating thickness,then finish making line with ordinary PCB craft,and then to plating/electroless deposition way to increase the thickness of the line, the preparation of DPC way contains vacuum coating,wet deposition,Exposure development, etching and other processes. Advantages: >In terms of shape processing, DPC ceramic plate needs to be cut by laser, the traditional drilling and milling machine and punch machine can not be accurately processed, so the combination force and line width is also more fine. >The crystal performance of the metal is good >The flatness is good >The line is not easy to fall off >The line position is more accurate,the line distance is smaller, reliable and stable, can be through the hole and other advantages.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Laser Nozzle Holder Information: 1.Imported ceramics + high quality special alloy 2.Ensure the consistency of thermal expansion of ceramic ring materials Prevent burst 3.The ceramic body and the alloy are closely connected, which is not deformed when heated. 4.The surface finish is high and the air flow is smoother. 5.Signal stability high sensitivity 6.The imported conductive adhesive and gold-plated copper needle have good conductivity,high sensitivity,good follow-up,effective insulation, and reduce the demage caused by impact. 7.Widely used: It is suitable for laser cutting heads of various brands Product Paramaters: 1.Material: Imported Ceramic High Quality Specical Alloy 2. Thread: M5 - M14 3. Outside Diameter: 17.5 - 41mm 4. Height: 4 -34mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Boron nitride can be long-term used at 1800 degrees under vacuum atmosphere. With gas protection, Boron Nitride can be used at 2100°. Boron Nitride is with high thermal shock resistance, no cracks under extreme cold & high temperature. If you take out Boron Nitride from 1000 degree furnace and colding it within short minutes. It still won't break even repeat this test with 100 times. > Matching materials: BN-99, BN-AL > Advantages: high temperature resistance (2000℃), thermal shock resistance, high electrical breakdown strength (3 -4 times that of alumina), carbon atmosphere corrosion resistance is much stronger than alumina > Used for polysilicon ingot furnace, graphitization heat treatment furnace, vacuum sintering furnace, atmosphere furnace ect. Grades 5 grades of boron nitrides are involved in Boron Nitride product series. * BN99 ● CABN ● ALBN ● ZRBN ● ZABN ● SB

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Aluminium Oxide, Al2O3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range of purities with additives designed to enhance properties. A wide variety of ceramic processing methods can be applied including machining or net shape forming to produce a wide variety of sizes and shapes of component. In addition it can be readily joined to metals or other ceramics using metallising and brazing techniques. Alumina based ceramics are by far the largest range of advanced ceramics made by INNOVACERA. Due to the important combination of properties, we have thoroughly researched the behaviour and characteristics of our Alumina products to give you the best possible component. Typical Alumina characteristics include: Good strength and stiffness Good hardness and wear resistance Good corrosion resistance Good thermal stability Excellent dielectric properties

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Rotary Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Durable Zirconium Oxide Ceramic Scalpel/INNOVACERA Technical cutters made of reinforced zirconium oxide ceramics are the standard material of choice in many machines and applications. we can supply product upon request. Product features: 1,Faster cutting rates 2,Consistently good cutting quality, e.g. improved strength of spliced connections 3,No corrosion 4,Smooth running 5,Extended maintenance intervals 6,Universal cleaning possibilities using acids, alkaline solutions and organic solvents Product application: 1,textile industry 2,Medicine 3,Food and beverage production 4,Automotive

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Trapezoid Blades are very suitable for fibers, tapes, film, leather, paper cutting machine application. Our material is yttrium stabilizes zirconia ceramic. Unlike other ceramic matetials, Zirconia ceramic is a material with high flexural roughness.Therefore it is not fragile and proper for producing blades. Another advantage is very sharp. Cutting performace is better than Tungsten carbide. Features: 1. Faster cutting rates 2. Consistently good cutting quality, e.g. improved strength of spliced connections 3. No corrosion 4. Smooth running 5. Extended maintenance intervals 6. Universal cleaning possibilities using acids, alkaline solutions and organic solvents

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 37Ω±15% Dimension: L80*φ5.0mm Electrode: Welding 2 nickel wires on the surface

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Product Specification Application: Mainly applied to the electronic soldering iron Voltage: 110VAC Heating Resistance: 310Ω±10% Dimension: L60*φ3.8mm Electrode: Welding 2 nickel wires on the surface

Request for a quoteResults for

Ceramics - Import exportNumber of results

517 ProductsCountries

- China (220)

- Turkey (66)

- Germany (44)

- Ukraine (37)

- Viet Nam (25)

- Austria (24)

- United Kingdom (17)

- France (15)

- Italy (15)

- South Korea (7)

- Belgium (6)

- Hungary (5)

- Slovakia (5)

- Netherlands (4)

- Namibia (3)

- Peru (3)

- Portugal (3)

- Spain (3)

- India (2)

- Ireland (2)

- Lithuania (2)

- United States (2)

- Estonia (1)

- Greece (1)

- Iran (1)

- Japan (1)

- Romania (1)

- Russia (1)

- Sweden (1)

Company type

Category

- Ceramics (233)

- Ceramic, components - electric (214)

- Ceramics, industrial (148)

- Ceramics, refractory (38)

- Ceramics - tiling (31)

- Tiles (29)

- Ceramics, handicraft (22)

- Tile and tile floors, porcelain (22)

- Import-export - chemicals and pharmaceuticals (21)

- Moulds, ceramics (17)

- Ceramic manufacturing - machinery and equipment (13)

- Ceramic, crockery (9)

- Taps - adjustable controls (6)

- Bathroom accessories (6)

- Porcelain - products for industry (6)

- Cutting - machine tools (5)

- Refractory materials and products (4)

- Stoneware tiles (4)

- Unit heaters (4)

- Bearings - ball, needle and roller (3)