- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wedge

Results for

Wedge - Import export

LEON ENGELBRECHT DESIGN CC

Namibia

Developed by a team of dedicated moms and committed medical professionals. These high quality products will become an essential tool for parents to settle both contented and fussy babies. It is so much more comfortable than the standard hard mattresses and wedges, and enables parents to transfer a settled baby, out of arms and into their new Place of Sleep / Moses Basket. This Nesting Cushion assist in giving your baby a comforting sensory environment to ensure a smooth, easy transition from womb to world. This nesting cushion is designed for the smaller full-term baby or the healthy premature baby. It can be used from birth and fits into incubators and hospital bassinets, as well as our Moses Baskets. The Wedge is available covered or uncovered. The cover is pure cotton and removable. The Wedge is used to ensure that your baby’s head is elevated.

Request for a quote

NORELEM FRANCE

France

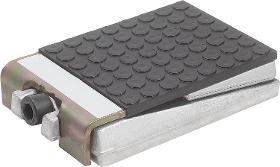

Steel, nitrile rubber. Note: The low non-slip levelling wedge is suitable for loads of up to 2 tonnes. The levelling wedge provides a large support surface with a nubbed structure made of nitrile with a hardness of Shore 80. Using the flat angle of the wedges, the height of the levelling wedge can be adjusted by 0.15 mm per turn of the screw. The vulcanized non-slip layer provides durable insulation from vibrations, noise, and corrosive media.

Request for a quote

NORELEM FRANCE

France

Steel, housing plastic, adhesive anchor steel. Note: Suitable for adjustment loads up to 12 tonnes. The heavy-duty anchors apply the centre double wedge principle. With the centre double wedge principle, the machine support height is adjusted by two wedges instead of one. The wedge movements are consistent and free of play. With the double wedge, the force acting on the lifting mechanism is halved and the central support point always remains rigid and stable. The spherical machine support on rounded discs can compensate for unevenness in the floor. Horizontal movements are prevented by the centring sleeve which holds the floor bolt in the form of an adhesive anchor. Application: Example applications of the levelling wedge are for levelling heavy machine tools, high-speed milling machines, and transfer machines

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

KNIGHT OPTICAL (UK) LTD

United Kingdom

We supply a range of Wedge Prisms for a range of applications. All individually QA checked, and metrology tested for quality to ensure parts meet customer specification. Supplied in a range of sizes and shapes with custom coatings tailored to meet your individual applications. Knight Optical supply precision optical components to customers within Forestry. Wedge Prisms are used in a similar manner to an angle gauge, when plotting the basal area of a group of trees. Wedge prisms are also used in beam steering. All our Wedge Prism are fully inspected on their quality in our ISO 9001 certified, state-of-the-art Metrology laboratory, using our Starrett AV300 Video Imaging System and our Trioptics PrismMaster. This allows us to work to the highest QA standards and meet the tolerance specifications on these precision components. Read PDF for more...

Request for a quote

GSW SCHWABE AG

Germany

Motorized rotation Hydraulic wedge type expansion Highend arbor with double bearing Extremely stiff design SHDH Series PullOff Reel with manually adjustable brakes SHDR Series Payoff Reel with threephase motor Pneumatic or hydraulic hold down arms Electromotive or hydraulic traveling feature w optional automatic centering Hydraulic coil car and fullsize back plates Conical keeper rolls w optional motorized travel Larger mandrel heights and segments Vectorcontrolled drive systems for heavy coil weights Servo drive and control systems, etc.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

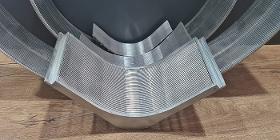

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

MSO MESSTECHNIK UND ORTUNG GMBH

Germany

Doppler Radar true-ground-speed Sensor

Request for a quote

NORELEM FRANCE

France

The functioning principle make the wedge clamps ideal for series clamping. The wedge form can exert high clamping forces. These wedge clamps can be mounted in grid holes or T-slots. Tightening the socket screw moves the wedge down and the jaws out pressing the workpieces against the fixtures fixed stops. The wedge has a slightly elongated hole allowing for movement to compensate for tolerances. Spread width: M8 = ±0.5 mm M10 = ±1.0 mm M12 = ±1.0 mm M16 = ±1.5 mm Drawing reference: D) DIN 6912 cap screw 1) Jaw face smooth 2) Jaw face serrated 3) Wedge clamps 4) Workpiece 5) Fixed stop

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Thus, centrifugal wedge wire screen is suitable for the different kinds of applications where accurate filtration is required. Advantages Special surface treatment Centrifugal customizable basket design Corrosion resistance Durable and long service life Precise filtration Strong mechanical properties Applications Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. Mining Applications Water Treatment Chemical Fertilization Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

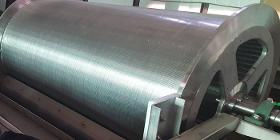

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SPANSET SECUTEX GMBH

Germany

The secutex material may be sawn using a conventional band saw. The material will attempt to resist the cutting tool. Use as low a wedge angle as possible and, if necessary, adjust the cutting speed.

Request for a quote

KARAPHARM

France

Design and manufacture of positioning wedges for the medical profession. Wedges to hold patients in fixed positions during X-rays, surgery or medical examinations. Manufacturer of positioning wedges for the medical sector

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages Special surface treatment Suitable & customizable design Long service life High durability – less maintenance Effective filtration The most popular usage of the panel filter screen is eliminating the big particles over the screen with vibration. Applications Food and Mineral Processing Water Cleaning Mining Applications Vibrational Separation Fermentation Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

MIHLA INSAAT MALZEMELERI SAN VE TIC LTD STI

Turkey

Superior performance wedge dowel (carbon steel) for high static and seismic loads in cracked concrete Material, corrosion: Carbon steel, zinc plated Head configuration: External thread Approvals / test reports: ETA, FM (Factory Mutual), Seismic, Fire Features More economical, optimized dowel designs – wider embedment depth range, flexible edge and spacing allow more economical designs to be created using smaller base plates and façade brackets Faster and easier correct installation – no hole cleaning required (M8-M20) and ready for automatic pre-tensioning with Hilti Adaptive Torque tool (M8-M16) Design support available – use the PROFIS Engineering Software Suite to simplify steel-concrete connection design or contact your local Hilti Engineering Team for advice on more complex projects Easier inspections – head marking showing dowel type and length simplifies quality control after insertion

Request for a quote

AVK REWAG

Netherlands

Support bush is manufactured from stainless steel AISI 304. In order to prevent corrosion, the support bush is pickled and passivated. Standard sizes are SDR 11, SDR 13.6, SDR 17 and SDR 17.6. Other SDR sizes are available on request. Available for PE pipes DN 50 – DN 400. Other DN sizes are available on request.

Request for a quote

UBIOTEX QUALITY LIFE S.L.

Spain

EFFECTS AND ADVANTAGES Relaxation and comfort. COMPOSITION Bamboo and foam INTÉRIEUR. DIMENSIONS 39x38x8 MANTEINANCE Hand wash or machine with nonabrasive products .Maximum temperature 30° You can not use bleach.You can boardYou can tumble dry.

Request for a quote

UBIOTEX QUALITY LIFE S.L.

Spain

EFFECTS AND ADVANTAGES It favors the posture. COMPOSITION Foam core. Bamboo vegetal fiber cover MAINTENANCE Hand or machine washable cover with nonabrasive products. Maximum temperature 30ºC. Bleachers cannot be used. Can be ironed. Can be tumble dried.

Request for a quoteResults for

Wedge - Import exportNumber of results

48 ProductsCountries

Company type

Category

- Filtering equipment and supplies (8)

- Water treatment, industrial - systems and equipment (7)

- Furnishings, cushioned (2)

- SMALL METAL PARTS (2)

- Shoes for sensitive feet (2)

- Shoes, men's (2)

- Anti-corrosion products, chemical (1)

- Axles, vehicle (1)

- Beds, bedsteads and mattresses (1)

- Clamp collars, plastic (1)

- Construction - Machines & Equipment (1)

- Crackers and snacks, salted (1)

- Espadrilles (1)

- Filters, liquid (1)

- Inductive sensors (1)

- Injection moulding of rubber and plastic (1)

- Lifting equipment (1)

- Metal straightening machines (1)

- Milking - machinery and equipment (1)

- Motor mechanics - hand tools, non power (1)