- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal bending for tubes

Results for

Metal bending for tubes - Import export

NINGBO TOWER INDUSTRY CO.,LTD

China

All of our products are customized by customer's drawing. Please feel free to send us your inquiry.

Request for a quote

MAHERAS LTD.

Bulgaria

We have 2 tube bending machines. One for small radii and one for large radii.

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

We provide our customers with the opportunity to get their materials processed before they even leave the warehouse – providing a leaner and more cost-effective manufacturing process. With large quantities of material stored on site, you’ll benefit from shorter lead times and better material availability compared to third party subcontractors. Thanks to recent investments, our manipulation service operates across two sites, equipped with several single and multi-stack benders and end-forming machines. Through these sites, we provide CNC and Press tube bending, end-forming and cruxiforming - providing the Group the capability to process and deliver orders faster than ever before. Our manipulation services are currently being employed within the automotive, domestic appliance and filtration industries.

Request for a quote

PI-METÁL

Hungary

We provide high quality CNC operated bending service We are able to bend on wide variety of angles tubes, pipes up to 81 mm diameter We can also bend square shaped profiles Processing pace is highly adjustable, that gives us ultimate control over the angle. Our ABM 76 CNC 1 Tube Machine bends tubes hidraulically up to 76 mm diameter with high quality This powerful machine provides convenience, prevents waste of time and increases efficiency, carrying out bending process consecutively and automatically with its advanced CNC feature

Request for a quote

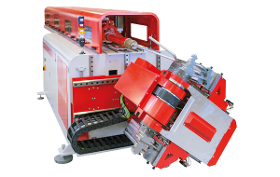

SCHMALE MASCHINENBAU GMBH

Germany

Our Speedmax is the fastest available wire and tube forming automation solution available on the market for bending machines. By combining NC finger benders with our servo-electric transfer, the Speedmax with its 90 servo axes can reach a speed of up to 4,000 machining steps per minute. The SPEEDMAX is available in three variants (S,M,L). The SPEEDMAX (S) has 20 processing stations and can produce up to 200 parts per minute. The machine concept combines the advantages of 3D-NC wire bending and wire bending by slides. Bending, embossing, notching, flattening, joining, punching, swaging of tubes and wire are possible production technologies in the 20 processing stations. The new SPEEDMAX L has actually 20 processing stations and can produce up to 60 parts per minute. The SPEEDMAX L can work with tube and wire up to a diameter of 12mm and a feed length of 50cm. Various bends in all levels and in the current equipment up to four swaging processes are possible.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Maximum bending freedom. The robotic bending technology combines the greatest versatility in manufacturing steps and simple handling. The robotic head is equipped with a clockwise and counterclockwise bending head, so that bending can happen in both direction once clamped. The eight synchronized and fully electric axes give maximum versatility when processing tubes. The bending process on tubes, including the processing at the ends and addon component can be done without any problems. The addon components can be positioned automatically, if needed. A radii/plane changer with up to 6 tools per bending system is integrated to give maximum flexibility..

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

We have developed these t bend machine solutions strong> for fast and efficient processing times. They are specifically tailored to the challenges of individual bends. Whether the system is manual or automated, they will deliver the best possible results. Highly efficient This manufacturing accelerator offers the profitable efficiency of our high performance bending machines for the manufacturing of hydraulics fittings together with Top Speed that is what the "AB" series stands for. For individual bends from 1xD to 1,500 mm bending radius for small and large radii, for demanding materials with thin walls, the high performance (HP) machine series guarantees the perfect bending result.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Stable, flexible and economical. This series will win you over with its special stability and performance. Individual pieces and small series can be produced in an extremely economical manner with this machine concept. The use of highvalue components ensure the machine's durability.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

For better efficiency. The electric axes can be programmed in synchronicity to give optimum cycle times.Tools for bending on multiple levels with automated tool change makes it possible to achieve various radii and the most extreme geometries on tubes. With our clockwise/counterclockwise bending machines – also available with push bending function – the most complex bends become reality with great accuracy.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Compact and very efficient. Our fully hydraulic mandrel bending machine delivers outstanding bend quality and very simple handling, with SPS control for preselection and storage of bending angles via a touch panel.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The smart companion for many different sites a great variety of machine sizes are available, from 6 mm to 115 mm. This unmatched, tried and tested transfluid classic is a compelling option, thanks to its many benefits, its good price/performance ratio, its very simple, but effective technology and unique quality.

Request for a quote

ESTIMET SP Z O.O.

Poland

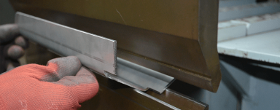

We provide sheet metal bending services using three precision Trumpf press brakes (TruBend_3100, TruBend_5085; TruBend_5320) with a maximum pressure of 320 tons and a maximum bending length of 4000 mm. Our well-equipped inventory of bending tools enables us to manufacture even the most complex parts, and dedicated software supporting machine operation allows us to simulate the bending process. All this guarantees the execution of orders with extreme precision and accuracy. In addition, in our machine park we have two CNC bending machines for bending pipes and profiles. We operate on both mandrel and mandrelless benders, while specializing in bending pipes and profiles. In our plant we deal with bending of, among other things: - structural steel - galvanized steel - stainless steel - aluminum

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg Provide Tube Bending,Welding, Fabricating Services, Custom Stainless Steel,Copper, Aluminum Tube Bending Fittings. Our pipe bending & fabricating service is a cold machining technics for making pipe products, such as trolly handles & frames,chair brackets & backrest, Bathroom pipe faucet, Safe handrails in sports places, Horticultural accessories. That means all material should be in structure of pipe, then machining by pressing machines (pipe bender) to different flexual figures,and most pipe products need drill holes,pipe necking & expending, oblique cutting,etc. Generally pipes still need to be polished and surface treatment after machined, such as painting, powder coating, chrome plating,chemical polishing,anodizing. We specialize in pipe(tube) bent & fabricated products many years, can produce curved pipes from aluminum pipe, stainless steel pipe, carbon steel. if you want custom tube bending fittings from China, welcome send inquiry to us.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in aluminum tube bending services more than 10 years, we have produced various types of aluminum tube bending fittings from different, include welded tube and seamless pipe, Elliptical tube and rectangular tube. we produce tube bending components from materials of stainless steel tube, aluminum tube, carbon steel tube, brass & copper tube. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge machine, precision pipe cutting machine, welding machine, drilling Machine, etc. We have a variety of tube processing equipment, such as automatic tube bending machine, semi-automatic tube bending machine, double-head tube bending machine, curved arc machine, diameter shrink machine,diameter enlarge mac

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

China Tube Components Manufacturer Custom Metal Tube Handles Of Aluminum Alloy, Carbon & Stainless Steel Tubes Tube end forming: A forming process used to create a specific end, usually to allow the tube to connect to another media. Cutting: The cutting process allows for metal tubes to be cut into specific shapes and sizes. Examples include tube laser cutting and mechanical cutting. Notching: This process creates notches at the end of the tube to simplify welding processes or to attach the tube to another part. Swaging: Swaging uses a die to manipulate the size of the tube diameter using force. Custom Metal Tube Forming Components, Seat Frame, Tube Handle, Yacht barrier... sales@mxmparts.com

Request for a quote

MARXAM PROJECT

Poland

CNC bending of sheet metal technology is the most popular method of plastic processing, allowing to obtain details of both simple and complex shapes. The use of modern press brakes allows for the maximum possible repeatability in cnc bending of the produced elements for any number of items. The modern CNC tube bending services and the automatic compensation of the deflection arrow give maximum accuracy and repeatability in 7 axes and allow you to maintain the required angles along the entire length of the bending line. An extensive tool park allows us to adapt to any customer’s technological requirements. We offer sheet metal bending services, such as tube bending, metal curving, metal sheet folding, aluminum sheet bending, bending steel and many more.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ATOM KARINCA LASER

Turkey

With our four-roll cylinder bending machines, we can perform cylinder bending for parts that are 3 meters in length, 150mm to 600 mm in diameter. And maximum thickness is 15 mm.

Request for a quote

OREMUS S.R.O.

Czech Rep.

The basis of efficient welding process is precision bending on modern machines. In our case, TruBend 8400 Press Brake offers a maximum bending width up to 4000 mm with pressure of a respectable 400 tons.

Request for a quote

SC PROFINOX SRL

Romania

We provide CNC bending services, performed according to the highest standards of quality and precision, using Abkant’s highperformance bending technologies. We carry out various CNC bending operations, depending on the customer’s wishes and needs metal bending, CNC pipe bending, bending of elements obtained through other technological operations. We value the quality of the products and services we offer and ensure that CNC bending operations do not deviate from this principle. For the results we achieve to meet the expected quality standards, we rely on the bestperforming machines in the industry – Abkant bending technologies. Abkant bending machines are ideal for bending metal sheets, CNC pipe bending, but also for bending cut parts, proving highly efficient even in the most difficult radii. Abkant CNC equipment is renowned for the “intheair bending” technique it uses, allowing very precise bends.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Finger bender technology on our X2000NC This is new and revolutionary! Do you know our X2000NC? Then you know the advantages of our variable, modular machine concept. In this new model, we have consistently transferred the finger bending technology of the SPEEDMAX to the X2000NC. This model now combines all the advantages of two bending worlds. By integrating the NC bending technology in combination with our rotary positioning pliers and the servo transfer, the X2000NC is now pushing material speeds to a whole new level. E.g.: Up to 40 parts per minute, each one with up to 6 bendings and 1 press operation is possible

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Metal bending is one of the most common metal fabrication operation. The sheet metal bending process involves applying a force to a sheet metal part to change its geometry. This force causes stress on the sheet metal beyond its yield strength and permanent physically deform without breaking or failing. The press brake is a commonly used equipment for sheet metal bending. It works by lowering a mould onto a sheet metal work piece positioned on a die, creating the desired form. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is laser cutting and bending. The material is stainless steel. The finish is cleaning and deburring.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

ESTIMET SP Z O.O.

Poland

Puristinjarruilla on mahdollisuus taivuttaa 5 000 mm: n pituisia elementtejä 225 tonnin paineella, jolla on runsaasti taivutustyökaluja, joiden avulla voit taipua jopa hyvin monimutkaisia elementtejä. Käytämme ohjelmistoa 3D-mallien kehityksen laskemiseksi. Koneemme ovat yhteensopivia useimpien CAD-formaattien kanssa. Puristinjarru on pääkomponentti, joka tarvitaan levymateriaalin taivuttamiseen. Siinä on tiettyjä mahdollisuuksia ja rajoituksia. Taivutusväline (matriisi, lävistys) päättää myös, voidaanko taivutusta tehdä. ESTIMET-yhtiöllä on hyvin laaja valikoima erilaisia taivutusvälineitä. Tämän ansiosta pystymme toteuttamaan jopa epätavallisimmat ja vaativat taivutuksen.

Request for a quote

ESTIMET SP Z O.O.

Poland

Böjning upp till 5000 mm x 225 ton Våra tryckbromsar har förmåga att böja upp till 5000 mm långa tryck med ett tryck på 225 ton med ett mycket rikt lager av böjverktyg som gör att du kan böja även mycket komplicerade element. Vi använder programvara för att beräkna utvecklingen från 3D-modeller. Våra maskiner är kompatibla med de flesta CAD-format. Pressbromsen är den viktigaste komponenten som krävs för att utföra plåtböjning. Det har vissa möjligheter och begränsningar. Böjverktyget (matris, slag) bestämmer också huruvida en given böjning kan göras. ESTIMET-företaget har ett mycket stort utbud av alla typer av böjverktyg. Tack vare detta kan vi inse även den mest ovanliga och krävande böjningen.

Request for a quote

ESTIMET SP Z O.O.

Poland

Our CNC presses can bend metal elements up to 5000 mm in total length, applying a pressure force of 225 tons, using an extensive inventory of bending tools to allow for forming even the most complicated elements. We use 3D model extension calculation software. Our machines are compatible with the majority of CAD formats. The CNC press is the main component required for bending a sheet of metal. It has a range of applications as well as specific limitations. However, the element that determines if a bending operation is feasible is the proper bending tool (matrix, punch). ESTIMET has a wide selection of all types of bending tools, which allow us to complete even the most non-standard and demanding bending operations. More informations about our bending possibillities you can find on our website: http://estimet.com/sheet-steel-bending/

Request for a quoteResults for

Metal bending for tubes - Import exportNumber of results

78 ProductsCountries

Category

- Bending - steels and metals (53)

- Pipes and tubes - ferrous metal (8)

- Pipe and tube fittings - non-ferrous metal (6)

- Sheet Metal & Tubes (5)

- Bending machine tools (4)

- Pipe and tube fittings - ferrous metal (4)

- Pipes and tubes, stainless steel (3)

- Turning - steels and metals (3)

- Forming - steels and metals (2)

- Construction, industrial - contractors (1)

- Cutting - steels and metals (1)

- Flexible tubes - non-ferrous metal (1)

- Folding machine tools (1)

- Gas and oil pipelines - installations (1)

- Industrial piping (1)

- Pipes and tubes - non-ferrous metal (1)

- Pipes and tubes, steel (1)

- Seamless pipes and tubes - ferrous metal (1)

- Shaping - steels and metals (1)

- Steel & Metal Transformation (1)