- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metal prototypes

Results for

Metal prototypes - Import export

MECHASYS GMBH

Germany

Laser cutting or laser fine cutting of metal, we can precisely process all metallic, non-toxic materials in material thicknesses from 0.2 to 2.0 mm. With our high-precision 1kW fiber laser (Nd: YAG with a wavelength of 1064nm) in combination with highly dynamic linear drives, we can produce your laser cuts in copper and brass. Due to our extremely small focus of 0.05mm, we usually create a cutting cag/ clearance of 0.07mm, so that the most delicate contours (especially inner contours) can be realized without mechanical stress, as the processing takes place without contact. This enables high-quality and precise prototypes and small series in contract manufacturing using cutting lasers. Accuracies of +/- 0.01mm, which are required in the sealing area for plastic overmolding for complete plugs or housings. Dimensions: sheet thicknesses from 0.2 to 2.0mm, max. sheet metal of max. 1,250mm x 1,250mm.

Request for a quote

3D PROTOTIPAI

Lithuania

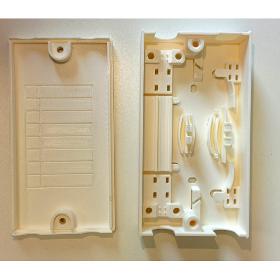

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

3D prototipai, UAB is one of the first and the biggest 3D printing and prototyping center in Baltic States. We help you to develop prototypes in metal and plastic. We also offer unique solutions for your specific products. Our creativity is infinite and after first contact we help to find out which method fit the best for your product.

Request for a quote

3D PROTOTIPAI

Lithuania

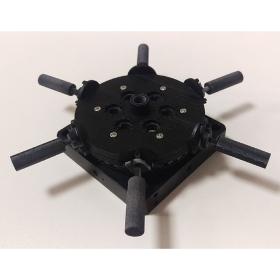

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

MECANUMERIC

France

The rigour and the accuracy for the industrial works, the polyvalence and the simplicity for a maximum of profitability. Designed for the accurate and intensive works, they allow a wide field of applications : metal engraving, fine millings, design, prototyping Refer to the exemples of applications : Moulds and models Health case or box Side windows Aircraft interior furnishing Jewels engraving Masks Household appliances Lights Furniture Aluminium frames The strengths • XYZ stroke 310 x 430 x 120 mm (DMC300) - "Y" reduced to 250 mm in case of automatic tool changer. • XYZ stroke 600 x 610 x 120 mm (DMC600) - "Y" reduced to 420 mm in case of automatic tool changer. • Rigid structure made of steel / Aluminium foundry. • Double guiding by prismatic rails in grinded steel with re-circulating ball bearings. • Ball screw with pre-stressed sockets. • Cinematics fixed table / mobile gantry. • Available in « servo-brushless » motorization. • Economical version with stepper...

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quote

3D PROTOTIPAI

Lithuania

For metal printing we are using special technology - Direct Metal Laser Sintering. DMLS is an additive process, when laser melts fine metal powder and builds up the product layer by layer. This method is perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end-use products. DMLS is used when strenght and funcionality of the product is very important. Technology allows tocreate products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts. DMLS technology is widely used in healthcare, automotive and aviation industries. Choosing different materials produces products with different characteristics such as flexibility, rigidity and durability.

Request for a quoteResults for

Metal prototypes - Import exportNumber of results

14 ProductsCountries

Company type