- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling design

Results for

Milling design - Import export

ROCHOLL GMBH

Germany

We love a challenge so we are more than happy to take on special designs. We translate your specifications into top-quality products. In order to meet the most stringent requirements, we rely on our comprehensive machine park and on the production facilities run by highly specialized partner companies. These machines have been designed to manufacture both individual items and batches without any problems. Would you like to have more detailed information on our special designs? Why not contact us directly? We will be happy to assist you. Milling of profiles Special concrete designs Rings for placing Shore test specimens Milling of dumbbell test specimens for tensile tests Multiple test specimens according to DIN 53281ff Stainless steel rings for tests according to EN ISO 10563 Spacers for standard joints according to ISO 11600 Spacers for elongation test according to ISO 11600, made of aluminum or PMMA in various % values Feed mechanisms

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

METAL TECHNOLOGY GROUP

Bulgaria

CNC turning machines Vertical CNC turning machines Vertical CNC milling centers Horizontal CNC milling centers Robotic cell designed for fettling and deburring of castings

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE capacitive sensors for use down to -230°C reliably detect deep-frozen liquid gases or granulates for cryogenic grinding, for example. The sensors are based on the proven capacitive principle. The measuring element of the sensor designed as a cylindrical capacitor. The medium to be detected functions as dielectric. The medium in touch with the sensor generates a capacity change. This is converted into a switching signal or an analogue 4...20 mA output signal. This applies both to conductive and on-conductive media. The sensors reliably record super-cooled liquid gases or granulate, for example for cryogenic milling. With their compact design the sensors of this series are well suited for installation in tight spaces.

Request for a quote

EQUILAB

Spain

The EQR-200 Vibratory Disc Mill is a milling equipment especially designed to obtain analytical granulometries of a great variety of samples, such as glass, earths, slags, metallic oxides, cements, ferroalloys, ceramic materials, amongst other. This unit is able to mill in no time an ample range of different materials, from the semi-soft to the hardest, fragile and fibrous. All the processes can be controlled via a digital full color screen. User-friendly and robust, it is a practically maintenance free equipment. Quick, easy to use, robust and efficient, it is also quite noiseless thanks to a careful acoustic insulation.

Request for a quote

COMERC SP. Z O.O.

Poland

The new generation of German Graf Equipment GmbH Gorilla pellet mills is especially designed for applications with very hard pelleting conditions in terms of raw material quality in limited working space and while keeping all production norms. The production of wood pellets is one of these applications. In fact, Gorilla is the first pellet mill designed for the biomass industry, including wood biomass, with direct drive system, without gearbox or V-belts. The new pellet mill performs a high efficiency thanks to its powerful torque motor, saving around 20% of energy, compared with the conventional drive systems. An unquestionable advantage of all Gorilla pellet mill is their modular design and a large die speed range (from 4 to 8 m/s) without loss of torque, which allows to meet even the highest technological standards of pellet production. Gorilla pellet mills assure superior finished pellet quality with a high PDI (Pellet Durability Index).

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

DRILLSTAR Taper mill is used to repair collapsed casings or tubings, and to shave off cement or corroded parts in casings. The taper mill hardfacing is designed to clean the casing without cutting it, and to penetrate very gradually. The upper part of the taper mill is long enough to allow the addition of stabilizing blades while still remaining easy to fish. DRILLSTAR Taper mill is available in two types, long or short. Blades, whether spiralled or straight, are fully customizable.

Request for a quote

SPM - SOCIÉTÉ PYRÉNÉENNE DE MÉTALLURGIE

France

Section mills are designed for cutting and milling a complete section of casing. All models 4 1/2 in. OD and above are equipped with 2 sets of 3 knives: 1 long set and 1 short set, designed for first cutting and then milling the casing. Knives can be hardfaced with your choice of TOPLOY carbide grains or TOPMILL/SWORDFISH tungsten carbide inserts. For most jobs, TOPMILL inserts are strongly recommended to improve milling performance. This tool can be equipped with Flo-tel, which produces a sudden drop in mud pressure when the pipe is cut out, indicating the right time to start applying milling weight.

Request for a quote

OCV ITALIA

Italy

Owens Corning® Milled Fibers are designed to enhance mechanical properties, increase stiffness, improve dimensional stability, and minimize distortion under elevated temperatures. EXCELLENT DISPERSION & IMPREGNATION Predispersed nature promotes excellent dispersion in the matrix. Shortfiber thermoplastic compounds will show improved melt flow characteristics with shorter input fiber lengths. IMPRESSIVE AESTHETICS Fiber length and excellent distribution qualities provide a homogeneous, highly pigmentable surface with limited fiber prints and good color. ENHANCED PART STRENGTH Glass reinforced parts exhibit improved mechanical properties, modulus and dimensional stability. Powder Relatively freeflowing with a high bulk density for use in formulations requiring very uniform dispersion and short fibers with median fiber lengths typically in the range of 40 110 microns.

Request for a quote

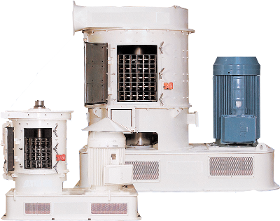

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

Makenas compact flour mill is designed for investors who want to establish a mill in a narrow space, with small capacity and limited budget opportunities. Milling machines have been specially designed in accordance with these needs. The assembly is made on a steel construction chassis. The mill, which is designed as modular, enables capacity increase in the long term. These mills can be transferred to another place when desired. In general, both initial investment and operating costs are minimal.

Request for a quote

KEDY

Turkey

Introducing the KEDY K10100 Roll Mill Lifting Equipment, the perfect solution for your heavy-duty rolling mill operations. Designed with the latest technology and manufactured from high-strength materials, the K10100 is built to last and deliver outstanding performance. With its impressive load capacity, you can rest assured that your work roll will be safely and securely lifted and positioned every time. The K10100's size and shape are carefully crafted to fit your specific rolling mill design, ensuring a seamless integration into your operations. The surface finish of the K10100 is of the highest quality, providing durability and protection against corrosion and wear. Its connection points, such as hooks and lifting eyes, make it easy to attach and position your work roll, while its safety features, such as locking mechanisms and safety straps, ensure the safe and secure handling of your equipment.

Request for a quote

STARRAG GMBH

Germany

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TS/TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TS/TFS NEO features a new milling unit and a modified Caxis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts. The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application. The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Request for a quote

MECANUMERIC

France

The rigour and the accuracy for the industrial works, the polyvalence and the simplicity for a maximum of profitability. Designed for the accurate and intensive works, they allow a wide field of applications : metal engraving, fine millings, design, prototyping Refer to the exemples of applications : Moulds and models Health case or box Side windows Aircraft interior furnishing Jewels engraving Masks Household appliances Lights Furniture Aluminium frames The strengths • XYZ stroke 310 x 430 x 120 mm (DMC300) - "Y" reduced to 250 mm in case of automatic tool changer. • XYZ stroke 600 x 610 x 120 mm (DMC600) - "Y" reduced to 420 mm in case of automatic tool changer. • Rigid structure made of steel / Aluminium foundry. • Double guiding by prismatic rails in grinded steel with re-circulating ball bearings. • Ball screw with pre-stressed sockets. • Cinematics fixed table / mobile gantry. • Available in « servo-brushless » motorization. • Economical version with stepper...

Request for a quote

MECANUMERIC

France

MECAPLUS-HP “AGILE” MACHINING High precision and performance solution HIGH PRODUCTIVITY 3 axes milling equipment : “AGILE” MACHINING • Designed and realized for an intensive use. • Heavy, fast, powerful, precise and efficient equipment, easy to operate for the machining of rigid sheet materials of strong thickness, in the fields of plastic processing, modelling, aeronautics, aluminium processing… or for the machining of molds and 3D models. • Particularly adapted for the machining of aluminium, plastic materials of strong thickness and composite materials with high mechanical properties. • Many customization possibilities. • Innovative and efficient vacuum tables with turbine technology or vacuum pumps. • Numerical controls SIEMENS or HEIDENHAIN type. • Quality kinematics integrating industrial components supplied by the world leaders in their field, mounted on welded stabilized steel frames.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

haacon hebetechnik gmbh expands its standard range to include rack and pinion winches with fastening lugs for wall mounting. The serial drive type is a spring-loaded safety crank (SiFeKu), which holds the load in any desired position under tensile and compressive loading. The winch can be utilised in any position. The winches are produced in three load classes: 1.5 t 3 t 5 t. The robust design with milled gear rack and hardened gear components is suitable for use in harsh applications. The crank handle can be moved for space efficiency. Special designs with other rack and pinion lengths, detachable crank design, assembled fastening options can be supplied at short notice.

Request for a quote

ENIGMA TOGGLE CLAMPS

Turkey

Heavy-duty clamps are extremely robust, handle heavy-duty clamping tasks with ease. Heavy duty to the alloy steel forging structure does not cause problems. For this reason, forged steel clamps are particularly preferred for welding and milling applications and more. Compact design, Hardened and ground surface stepped suspension bolts, hardened and H7 tolerance machined inner diameter bushings, weldable thrust arm, weldable action arm, 146 degree opening action arm to relieve workspace, Mounting base options.

Request for a quote

LMT TOOL SYSTEMS GMBH & CO. KG

Germany

LMT Tools has developed the CopyMax family, specially for the die and mold making industry The latest addition to the family is the one-sided indexable insert CopyMax1. It is an alternative for the reliable CopyMax2 with a two-sided indexable insert. opyMax1 and CopyMax2 prove their advantages above the competition during the roughing and the semi-finishing processes. Both tools are manufactured using the manufacturing process HQS (High Quality Sintering), which is registered for patent approval. For the first time, HQS allows for pressing and sintering a ball nose copy insert complete, resulting in precision sintered cutting edges. In addition to introducing the new indexable insert CopyMax1, LMT Tools has developed new shanks for the CopyMax. A cylindrical steel shank version is available in two different lengths, and the cylindrical bolt-on milling cutter are both new to the program. Both milling systems are designed with internal coolant supply.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BAYBAL MILLING MACHINES INDUSTRY AND TRADE LTD.

Turkey

The system hammer mill pneumatic system is designed to grind all dried vegetables, fruits and spices in a hygienic and high quality manner using a sieve and filter. The machines used in the system and all the parts that come into contact with the product in the machine content are produced in a hygienic and high quality manner by using 304 quality stainless steel. products that you can grind in this system (as dried products) You can micronize all dry products such as garlic, onion, parsley, mint, lemon, orange, tangerine, banana, ginger, turmeric, coriander, black pepper, etc.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The HammerKnife Universal Mill is the combination between a Hammer Mill and an Universal Mill. As the FORPLEX FNG Mill it can be equipped with different grinding tools (hammer plate ou blade plate) which are adjustable in relation to the product to be ground. The FK Mill has the same advantages as the Universal Pin Mill FNG easy to use, easy to clean, easy to maintain, but also simplicity of changing the grinding tools or grids. Perfect for technical applications such as the grinding of natural ingredients (knife rotor designed for the crushing of plants), the FK mill was designed to meet the standards of the foodstuffs industry, fine chemicals industry, pharmaceuticals industry, nuclear industry or even for cosmetics. It can meet FDA, GMP or ANIA standards and criteria. With the robustness and strength of hammer crusher

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The PAS integrated classifier mill is designed to treat a wide variety of products obtaining a particle size of 99% down to 10µm. The PAS is equipped with a grinding plate and integrated classifier that are driven independently by frequency variation motors. Different versions of the PAS are available, giving a wide flexibility in terms of installation and usage. The variety of grinding tools (plates, liners) when associated with a variable speed static and dynamic classifier guarantees a high quality ultrafine finished product for all applications. The PAS can be equipped with our latest patented technologies SEALMAX© new generation classifier, OPTICYCLE© internal ultrafine recycling system.

Request for a quote

POITTEMILL FORPLEX BROYEURS INDUSTRIELS

France

The ATTRIMILL is an attrition mill (or kinetic mill) principally used for plastics or fibrous products. It combines three physical principles that generate efficient ultrafine grinding. The autocomminution of the particles generated by the upward air spiral, The comminution of the particles created by pressure changes generated by variations in the air flux /matter projections against the blades and the stator, The shearing of the particles between the blades and stator grooves. The internal design of the mill depends upon the type of product and the required fineness. The range is divided into several versions according to the sector of activity and products to be treated Stainless steel for foodstuffs, pharmaceuticals or chemicals, ceramic lining for abrasive products, resistance to an accidental explosion (PSR 10 bars) etc... We have a full range from the ATM8 (several kg/h) up to the ATM600 (up to 25t/h).

Request for a quote

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Sophisticated drive concepts for ball mills and rotary kilns require powerful solutions. Eickhoff offers different gear solutions for the various drive concepts established in the field, such as side drive, central drive and direct drive. In addition to the robust Eickhoff helical gearboxes, our ED planetary gearboxes are preferred, especially for a central drive. They offer a compact solution with extremely high power density and are therefore also leading from an economic point of view. Even torques of over 7,000 kNm can be realised. Typical applications are the crushing of raw materials as well as the burning of cement clinker. The gears are characterised by a long service life and high power density.

Request for a quote

FIP ARTICOLI TECNICI S.R.L.

Italy

Legislation concerning acoustic pollution very closely affects all industrial activities, in addition to infrastructural road and railway activities, with special reference to continuous-cycle industries: graphic design companies, paper mills, steel plants, thermal power plants, food companies. Noise barriers in many cases represent the ideal solution of the problem of the maximum acceptable noise level at the border, leaving the plants free for maintenance; they also allow to reduce noise generated by transports and internal goods handling, screening the moving sources like trucks and forklift trucks. TECNOWALL metal panels are ideal for these structures, because they are very sturdy and cheaper than the other types featuring very special applications

Request for a quoteResults for

Milling design - Import exportNumber of results

25 ProductsCategory

- Flour milling - machinery and equipment (4)

- Industrial tools (2)

- Aluminium alloys (1)

- Fabrics for technical use (1)

- Fasteners, metal (1)

- Food extracts - machines and equipment (1)

- Fruit (1)

- Gears (1)

- Laboratory equipment and instruments (1)

- Lifting equipment (1)

- Machine tools, metal machining - parts and accessories (1)

- Measurement - Equipment & Instruments (1)

- Metallurgy - machinery and installations (1)

- Milling - machine tools (1)

- Milling - steels and metals (1)

- Milling - woodworking machinery (1)

- Sensors (1)