- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- nuclear power

Results for

Nuclear power - Import export

EC PLAZA

South Korea

We have experience in various fields such as real estate, transportation, resource environment, disaster and disaster, semiconductor, and nuclear power based on spatial information, and we are also investing continuously in the field of developing and providing spatial information solutions based on Excel. We are trying to become a place where people who dream of the future gather and make it together rather than going fast. This will also be a fast way to increase customer value.

Request for a quote

NOVELTY STEEL

Turkey

A pressure vessel is defined as a container with a pressure differential between inside and outside. The inside pressure is usually higher than the outside, except for some isolated situations. The fluid inside the vessel may undergo a change in state as in the case of steam boilers, or may combine with other reagents as in the case of a chemical reactor. Pressure vessels often have a combination of high pressures together with high temperatures, and in some cases flammable fluids or highly radioactive materials. Pressure vessels are used in a number of industries; for example, the power generation industry for fossil and nuclear power, the petrochemical industry for storing and processing crude petroleum oil in tank farms as well as storing gasoline in service stations, and the chemical industry (in chemical reactors) to name but a few.

Request for a quote

BILLI DICHTUNGSTECHNIK GMBH

Germany

In order to be able to meet the individual requirements of our customers, we offer various types of spiral wound gaskets: For example, you can choose between standard versions with a smooth surface and various special models. All articles are based on a stainless steel strip and high-quality filling materials such as graphite and PTFE, which underlines the excellent quality standard. The spiral wound gaskets of billi are characterized by a constant elasticity during hot-cold cycles. Classical applications in the chemical industry include all types of gas lines, directional valves and pumps. Furthermore, spiral wound gaskets are the optimal solutions for pressure vessel openings in steam systems as well as low and high pressure in nuclear power plants. For the best possible functionality of spiral wound gaskets, the careful considered choice of model is of central importance: the versions with centering ring, for example, assures an ideal fit between the bolts.

Request for a quote

INGAS LLC

Ukraine

Formula: He General Description: monoatomic, non-toxic, chemically inert gas, odorless, colorless and tasteless Gas purity and content of its controlled impurities(vol.%, ppmv) Brand 4.0 99,99% Brand 4.5 99,995% Brand 5.0 99,999% Brand 6.0 99,9999% Areas of use: Metallurgy - as an inert shielding gas for smelting pure metals; Welding industry - as an inert medium in arc welding; Food industry - as a packaging gas for food preservation; For gas-filled aircraft and weather probes and balloons in the entertainment industry; Breathing mixtures for deep-sea diving; Advertising - for filling gas discharge tubes; Nuclear power - as a coolant; Gas chromatography; Helium-neon lasers. Brand 4.0 Helium (He) 99.99% Neon Ne ⩽90.0 ppmv Nitrogen N2 ⩽20.0 ppmv Oxygen + Argon O₂+Ar ⩽6.0 ppmv Hydrogen H2 ⩽25.0 ppmv Amount of hydrocarbons ΣCₙHₘ ⩽5.0 ppmv Carbon monoxide + Carbon dioxide CO+CO₂ ⩽10.0 ppmv Moisture H2O ⩽20.0 ppmv

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Produced in Italy by NLMK Verona, which is become an undisputed producer of high quality forged blocks and bars, the ingots are available in a wide range of grades: •Case hardening steel •Heat treatable steel •Creep resistance steel •Martensitic stainless steel •Ball and roller bearing steel •Tool steel •Micro alloy steel •Nitriding steel •Tough at subzero steel •Pressure Vessel steel Applications : Oil & gas, wind power generation, shipbuilding, heavy engineering, nuclear power, automotive, etc. Category Case hardening steel Heat treatable steel Creap resistance steel Martensitic stainless steel Ball and roller bearing steel Tool steel Micro alloy steel Nitriding steel Tought at subzero steel Pressure vessel steel

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

Forged components for nuclear reactors, boiler systems, piping Valves are pivotal in various industrial contexts. Forged parts designed for nuclear reactors, boiler assemblies, pipeline construction, and safety valves are crucial elements in various industrial applications. Safety valves, typically pressure relief valves, stand out as paramount safety features within most systems. Their primary function is to safeguard pressurized vessels like steam boilers, reactor vessels, and pipelines from potentially hazardous pressure surges. In the event, that pressure exceeds safe limits, these valves release trapped gases, vapors, or liquids either into the atmosphere or into designated manifold systems. The West German drop forge KB Schmiedetechnik GmbH in Hagen (NRW) boasts decades of proficiency in crafting drop-forged components tailored for pressure applications compliant with the Pressure Equipment Directive (PED) and for nuclear facilities adhering to KTA, AVSD, and RCCM standards.

Request for a quote

KB SCHMIEDETECHNIK GMBH - A GERMAN DROP FORGE - CLOSED DIE FORGINGS - ALL STEEL GRADES

Germany

KB Schmiedetechnik GmbH is a drop forge in West Germany, located between the historic “blade & metal region” Solingen-Remscheid-Wuppertal and the “Borussia soccer city” Dortmund, specialized in small series production of safety-relevant closed die forgings from 200g to 130Kg unit weight of all steel grades and alloys according to following certifications and standards: pressure equipment: valves, boiler systems, piping PED 97/23/EG, AD 2000-W0, ASME/ASTM, CNIM, Alstom, MHPS nuclear power/ atomic energy and plant construction KTA3201.1, KTA1401, AVS D 100/50, Siemens, EDF/Areva/RCC-M naval architecture/ shipbuilding and offshore/ ocean engineering, certified by •American Bureau of Shipping (ABS) •Bureau Veritas (BV) •Det Norske Veritas (DNV) •Lloyds Register (LR) •Nippon KaijiKyōkai (ClassNK) Examples: components and equipment like brackets, holders, chain links, hoists, lifting hooks, fasteners, pressure-bearing parts like valve bodies, pipe connections, and more.

Request for a quote

RILLEX S.R.O.

Slovakia

Made-to-Measure protecting tarpaulin. Antistatic.

Request for a quote

BÜCHI AG

Switzerland

Corrosion testing requires the realistic simulation of the process environment. These environments often include HPHT (high pressure high temperature) conditions. Thanks to our proprietary designs and the use of high-performance materials our industry leading HPHT corrosion testing autoclaves are suitable for the most challenging corrosion testing applications. We have worked jointly with customers from various industries such as upstream and downstream oil & gas, petrochemicals, steel, nuclear and conventional power generation, inspection, certification and testing to design, engineer and manufacture customized corrosion testing solutions for their individual applications.

Request for a quote

DRALLIM INDUSTRIES LIMITED

United Kingdom

Our skilled staff specialise in solving the sort of engineering and manufacturing conundrums you’d rather do without. Our organisation is geared to producing one-off prototypes and small batch manufacturing; We take pride in overseeing the entire process, from design, prototyping and manufacture to delivery, installation, full product certification and after-sales service. With experience in providing comprehensive turnkey assembly test solutions covering electronic, electromechanical, engineering and mechanical products we offer our customers a total contract manufacturing service. When an order is received, a project plan is then developed; our team uses detailed documentation, engineering change and reporting control to ensure continued information integrity. An experienced project manager acts as the interface between Drallim and our customers although, at the same time, we actively encourage engineer-to-engineer communication.

Request for a quote

CHANGSHA PANRAN COMMERCE AND TRADE CO., LTD

China

PR600 series heat pipe thermostatic bath is the company’s unique product with completely independent intellectual property rights, and the main technical indicators are in the international advanced level. The enterprise standard Q/0900TPR002-2014 “Heat pipe thermostatic bath” is implemented in the production process. The working temperature ranges from -40℃ to +500℃, the effective working area depth can be up to 450mm, the distance from the upper port to the effective working area is usually not more than 100mm, the typical temperature difference in the effective working area is 0.03℃ (model-related), very suitable for the calibration work of the industrial thermal resistance, low temperature thermocouple, bimetallic thermometer, pressure thermometer, working glass liquid thermometer and second-class standard mercury thermometer. Application examples: 1. Calibration of nuclear reactor dedicated temperature meter of Dayawan Nuclear Power Station. 2. Calibration of transformer oil...

Request for a quote

ECLATS ANTIVOLS

France

Due to the recent events in Japan (the explosions at the Nuclear Power Station) these devices are required now more than ever! Description of "SOEKS" Personal Digital

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Superior Tube has a long history of supplying high quality metal tubing to the nuclear power industry going right back to its inception after World War II. It’s an area where strict compliance and integrity are absolutely critical. We have a track record of developing new solutions and helping the nuclear energy sector to advance. Our tubes are deployed in the cores of nuclear reactors, where they must endure in an extremely demanding environment for the entire life cycle of each reactor. Control rod and cladding tubing are critical safety components, as they are responsible for controlling the nuclear reaction and energy output within the core. Superior currently produces control rod tubing from 1.0” in outside diameter down to around .250” OD. If you have demand of products within or outside of this range, please contact us so we can provide a solution. Please note that we have a minimum order value of £10,000.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Economic and safe: Hydraulic bolt tensioning systems Single clamps or small clamps for opening and closing reactor pressure vessels or other primary circuit components As a specialist for the design, construction, supply and maintenance of highly automated bolt tensioning systems, we offer our customers demand-oriented solutions for opening and closing pressurized and boiling water reactors as well as other primary and secondary circuit components in nuclear power plants. Our range of services includes single and multiple bolt tensioning devices, bolt turning and handling systems, bolt and blind hole cleaning systems. Siempelkamp bolt tensioning machines reduce your operating sequences for opening and closing to less than 50 % compared to conventional methods

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Since the earliest days of the nuclear power, Superior Tube has been manufacturing high quality metal seal tubing and O-ring seals for use in reactors. For the safe running of nuclear generators, compliance with order specifications and the integrity of the metal parts are of critical importance. They have to last from the day the reactor is commissioned until the end of its life cycle, surviving extremes of heat and nuclear radiation. Today, O-ring and seal tubing components from Superior Tube are deployed in reactor cores across the world. Because of our track record delivering the highest quality O-rings and seal tubes, we have also been able to work with the nuclear industry to develop new solutions and help advance the technology. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

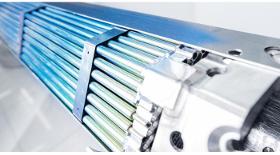

Heat exchangers – used to cool, heat or reheat fluids, gases and air – are an area that Superior Tube specializes in. We offer a range of products specifically meeting the demands of companies fabricating shell and tube heat exchangers. Our heat exchanger tubes are used in a wide range of industries such as chemical processing, hydrocarbon processing and oil refining, alternative energy, nuclear power generation and aerospace. The stainless steel and nickel alloys we manufacture are high strength, corrosive resistant alloys that maintain optimum performance in extreme conditions. Superior Tube heat exchanger products can be purchased as seamless, welded or welded and drawn tubes in a multitude of sizes ranging from 0.010” OD to 1.500” OD with wall thickness as light as .003” Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Major players in both the aerospace and nuclear power industries rely on Superior Tube for precision tubing to protect their control systems and instrumentation. Meanwhile, control and measuring devices critical to the safe functioning of nuclear reactors also require our high quality tubes. Within reactor cores, our instrumentation and control tubing encases equipment for monitoring various factors such as pressure, temperature, density differences and fuel burn up rates. It’s an extremely demanding environment where durability and reliability are absolutely critical. Superior Tube supplies instrumentation tubing in straight and coiled tube forms. The most common materials used are special grades of stainless steel and nickel alloys. Superior currently produces instrumentation tubing from up to 1.5” in outside diameter down to less than .020” OD. Please note that we have a minimum order value of £10,000.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TESLA ENGINEERING LTD - MAGNET DIVISION

United Kingdom

Nuclear fusion; the process that powers the Sun, releases energy by means of the fusing of two hydrogen atoms to form one helium atom. Adopting this process on Earth, as part of a next generation power station,1Kg of fusion fuel has the potential to provide the equivalent energy to 10 million Kg of fossil fuel, cleanly and from a potentially limitless fuel. Nuclear fusion reactions require the formation of a plasma of fuel, which can be achieved at temperatures over 100 million degrees. Sustaining this extremely thin and fragile plasma requires a sophisticated magnetic confinement system, which prevents contamination and cooling by the material surfaces. This is where Tesla come in. Tesla is supporting and enabling this international research effort, through the specialist supply of the critical magnetic confinement components for fusion experiments around the World, including: ITER MAST-U Tokamak W7X Stellarator JT-60SA ** Click for more **

Request for a quoteResults for

Nuclear power - Import exportNumber of results

19 ProductsCountries

Category

- Nuclear power stations (3)

- Pipes and tubes, stainless steel (3)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Data analysis (1)

- Electronics - import-export (1)

- Forges - machinery and installations (1)

- Gas mixtures (1)

- Heat exchangers (1)

- Magnetic equipment (1)

- Metal industrial presses (1)

- Nuclear power stations - installations and equipment (1)

- Oil-fired power stations, installations and equipment (1)

- Seals (1)

- Tanks, metal (1)