- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- perforation of steels and metals

Results for

Perforation of steels and metals - Import export

TABELARAIZ

Portugal

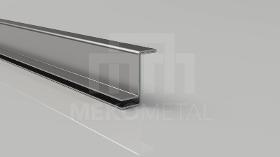

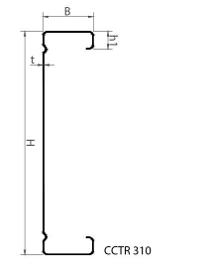

Profiles produced "C' Section characterized as CCTR 310. Discover our catalog here

Request for a quote

TABELARAIZ

Portugal

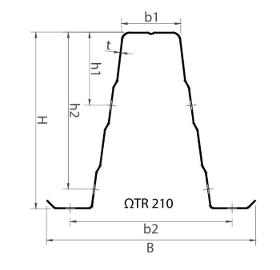

Omega sections characterised as ΩTR60, ΩT110, ΩTR160, ΩTR210, ΩTR260; Profiles sold in EN 10346 steel: Hot-dip galvanised Z:200, 275 | Zin+Mag:175, 250; Drilling is carried out according to the position indicated by the customer.

Request for a quote

ESTIMET SP Z O.O.

Poland

As one of our services we offer the finishing of edges in accordance with specific requirements and specifications. We prepare edges for further operations such as welding, painting, assembly or simply for their aesthetics.

Request for a quote

TECHNOGROUP

Bulgaria

As a company with long-term experience in metal painting, we suggest wet painting and powder coating. The choice of paints is made according to the clients’ preferences. The paints and the finish are chosen by the client. The client can choose between glossy, semi matte or matte color.

Request for a quote

TECHNOGROUP

Bulgaria

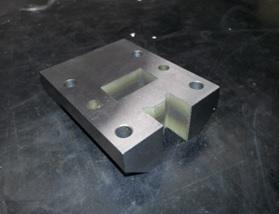

We are using CNC-Lathe and CNC-Milling machines in the detail manufacture. Thanks to our partners, we have succeeded to launch serial production and within the frames of low tolerance of materials of all kinds and quantities.

Request for a quote

TECHNOGROUP

Bulgaria

Our advantage lies in the ability to foldform steel in big quantities. Our advantage lies in the ability to foldform steel in big quantities. We use specific, simple or unitary figures of lengths, up to 4,000mm.

Request for a quote

TECHNOGROUP

Bulgaria

By using the latest fiber laser cutting technology, we have managed to achieve clearly defined results and improve the production process.

Request for a quote

TECHNOGROUP

Bulgaria

We use the latest technology in the welding processes as well. The company staff consists of professional welders with long-term professional experience. The certified personnel has worked on numerous high-quality welds.

Request for a quote

MR CO. LTD.

Ukraine

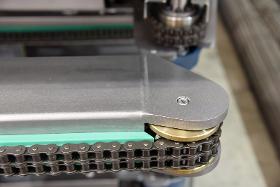

By the principle of operation, the coordinate punch press resembles an office paper puncher. The workpiece is pressed against the matrix. After that, a punching tool, the punch, strikes the workpiece with a force of up to 200 tons. In a fraction of a second, the punch and pressure ring return to their original position and the position-sensing mechanism moves the workpiece for the next strike. The capabilities of the equipment are not limited to the production of through-holes. Using punches of different sizes and shapes allows us to perform the most diverse tasks, such as countersinking, dimpling and forming. Modern coordinate punching machines are characterized by high productivity with moderate energy consumption.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

UKF STAINLESS LTD (THE UKF GROUP)

United Kingdom

Traditionally, perforated tube is manufactured through a lengthy operation starting with flat strip metal that goes through four stages of processing before completion. This is a time-consuming and costly procedure with chances for complications throughout the process. We’ve innovated the way perforated tube is processed by perforating pre-formed tube in one operation. This saves you time, money and hassle as it eliminates the long process and any production issues that can occur, while providing a visually enhanced product. Our five perforating machines can perforate stainless steel, titanium and aluminium tubes from 38mm to 101.60mm⌀, in lengths up to 750mm long. The specialist tool design allows tube perforation in various patterns that can be tailored to produce bespoke and unique patterns and shapes.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OREMUS S.R.O.

Czech Rep.

Our work starts with precise and efficient material cutting using modern machines. Our Laser and plasma cutters are available for sheet metal processing of all grades. Laser Trumpf 4kW with interchangeable table 4000x2000mm cuts mild steel of max. 18mm with both oxygen or nitrogen. Plasma Omnicut/Hypertherm where portal is also fitted with an acetylene burner; table size 6500 x 2000mm, usually cuts max. thickness 100mm

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

large aluminium milling operations

Request for a quote

OTTO EICHHOFF GMBH & CO. KG

Germany

Turned parts Long turned partes, small turned parts Turned, milled and grinded parts Thread inserts in brass, steel and stainless steel Possible materials: Alloy AlCuMgPb, AlZn5,5MgCu etc. Brass CuZn39Pb3, CuZn40Pb2 etc. Stainless steel 1.4301, 1.4305, 1.4571, 1.4401, 1.4101 etc. Steel Machining steel, St52, St37, C45, etc. Special steels Titan, Hastelloy, Copper, Bronze etc. Surface treatments may be done as follows: Galvanizing, nickel, brown, hot-dip galvanizing, phosphating, anodizing, chrome plating, painting, powder coating, plasma coating, sandblasting, Tuflok coatings. All common surfaces as VDA standard are possible (zinc-nickel, zinc flake). Heat treatments such as Plasma / gas nitriding, carbonitriding, hardening, carburizing, vacuum hardening, tempering etc.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

The process is CNC laser cutting and bending. The material can be stainless steel or aluminum.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

CNC Turning aluminum part

Request for a quoteResults for

Perforation of steels and metals - Import exportNumber of results

81 ProductsCountries

Company type

Category

- Steels and metals - machining (40)

- Turning - steels and metals (27)

- Milling - steels and metals (22)

- Bending - steels and metals (21)

- Cutting - steels and metals (19)

- Perforation of steels and metals (17)

- Folding - steels and metals (12)

- Steel & Metal Transformation (7)

- Steel & Metals (4)

- Sintering - steels and metals (3)

- Forming - steels and metals (2)

- Galvanization - steels and metals (2)

- Grinding - steels and metals (2)

- Pipes and tubes, stainless steel (2)

- Straightening - steels and metals (2)

- Boring - steels and metals (1)

- Finished Metal Products (1)

- Grids, metal (1)

- Laser - cutting and welding machines (1)

- Mechanical engineering - custom work (1)