- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- presses for massive forming

Results for

Presses for massive forming - Import export

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The O-forming press applies a press force of 4,000 metric tons per meter of pipe. This is necessary to form today’s material grades above X100 to the desired round shape at the optimum level of reduction. The control concept with (patented) multi-cylinder parallelism control ensures that the moving beam maintains a position parallel to the press table with a tolerance of +/-1 mm/m over the entire length. Combined with our tools, this results in a precise pipe gap which leads to signicant time and material savings for the subsequent welding process. The intelligent sensor and control concept of all main cylinders ensures that dierent sheet lengths (e.g., residual lengths) can be processed. The press is powered by either conventional drive concepts or via frequencycontrolled drive concepts. Our ECO Drive uses the high moving load of the moving beam to generate energy during the controlled quick lowering of the beam. This energy is fed back to the power network.

Request for a quote

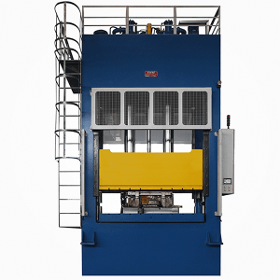

OZKOC HYDRAULIC MACHINE CO.

Turkey

In processes which requires single effect, Ozkoc offers variety of solutions between 70 to 7000 tons with extractors or complicated solutions with mold core in case of need. Please contact our specialists for choosing most suitable Hydraulic Press specifications for your production.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp is number one in tailor-made plants for the leading manufacturers of pipeline pipes. These large-diameter pipes with longitudinal weld seams are manufactured using crimping, U-forming, and O-forming presses. Compared to other processes on the market, these three presses achieve high production outputs of up to 30 pipes per minute regardless of the pipe diameter. For these large presses featuring our proven metal frame construction, the heavy component parts and tools are manufactured in our in-house foundry. The three hydraulic presses present the essential forming units of a modern production line for longitudinally welded pipes with lengths of up to 18 m in three forming steps. For each of the three forming steps, Siempelkamp oers the optimal press and the associated equipment for the forming line (e.g., pipe transport, lubrication, measuring).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Presses for massive forming - Import exportNumber of results

3 ProductsCountries

Company type