- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pressure moulding

Results for

Pressure moulding - Import export

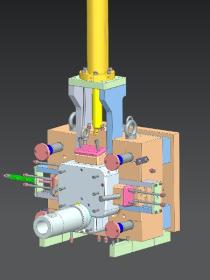

MOH D.O.O

Slovenia

components for making tools for Rubber injection plastic injection high pressure aluminium injection moulding low pressure injection components for making cutting tools components and construction of clamping devices housings holders

Request for a quote

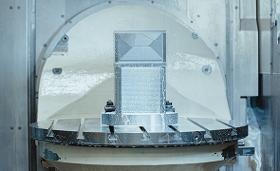

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Our patented material is highly suitable to produce foam moulds and RTM pressure injection moulds. Advantages: • Large volumes of more than 2500 kg can be cast in less than 45 min. • Good castability • Hardly measurable linear shrinkage • High temperature resistance • Demoulding process after approx. 90 min. (after adding the last backfilling compound) • Chemical adhesion to polyester or vinylester gelcoat • Immediately after the first mould half has cooled down, the second mould half can be prepared • Copper pipes keep the mould surface on a nearly constant temperature • Post-curing is not necessary ALWA MOULD D backfilling compounds are the fastest system on the market. For the surface you can chose between two gelcoats: 1) ALWA MOULD COAT This is a vinylester gelcoat that is especially suitable for high-end surfaces. It can be polished to high-gloss. 2) ALWA EPF 10 This is an epoxy gelcoat that is easy-to-use and is recommended for parts, where high-gloss surfaces are not needed

Request for a quote

J.D. GECK GMBH

Germany

Use our industrial manufacturing expertise for your products too ,Manufacture of silicone or aluminium moulds ,Gas internal pressure procedure (GIP) Processing of sheet plastic (cutting, milling, bending) More information available at https//www.geck.de

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD P is a cold curing casting resin for the production of porous moulds, slabs and blocks for the ceramic industry. It is a porous and high-strength plastic, which is well-suited for high pressure casting applications. ALWA MOULD P can be used in various areas of the tableware and sanitary ceramics, technical ceramics, plastic mould procedure as well as various filtration processes. The high stability and defined porosity of the material allows highly accurate mould surface reproductions. With ALWA MOULD P various geometric moulds for filtration processes of suspensions can be produced. ALWA MOULD P can be used for ceramic slip pressure casting procedures. In this procedure, water is removed by a filtration process of a clay suspension (slip), so that an increasing clay layer is built on the mould wall over time. The moulds, slabs and blocks of ALWA MOULD P are easily machinable (e.g., drilling, milling).

Request for a quote

MVA D.O.O.

Slovenia

We offer product design consultations, tool designing, mould manufacturing and mould maintenance and service.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

HEXPOL TPE GMBH

Germany

In the injection moulding process TPE pellets are fed into the machine through a hopper and then into a heated barrel. The heat from the barrel turns the material into a liquid resin which is then injected into a closed mould under high pressure. After allowing the molten polymer to cool, the finished part can be removed from the mould. Injection moulding is a high-volume, high tooling cost process, the advanced properties of our TPE compounds deliver short cycle times allowing parts to be produced at a rapid rate. The information below is intended as a general overview, settings may vary depending on the specific grade selected. Please CONTACT US for detailed processing information Settings Equipment Conventional injection moulding machine Compression set At least 2:1. Special screws with short sections and higher compression ratios (3:1 to 4:1) may be good at low screw speeds Shrinkage Between 1.0% and 2.5% depending on the grade, type of application and location of the gate. Moul

Request for a quote

EKOMAXI MODULAR WATER STORAGE SOLUTIONS

Turkey

Modular panels of water tanks and water conservation tanks are manufactured on high-pressure hydraulic molding presses under-regulated high temperatures from GRP or SMC (glass fiber reinforced polyester resin.) Application of regulated heat and pressure make GRP or SMC structure very strong and rigid. Manufactured according to the world-renowned WRAS and EN 13280: 2001 quality management system. GRP Modular Water Tanks ceilings, floors and sides surfaces are all made of hot pressing. This highly qualified engineering product is the best and most preferred among water storage. • Very long life • Low weight • Resistant to corrosion • No electrical conductivity • Low thermal conductivity • Has dimensional stabilizers • Resistant to UV rays • Hygienic according to all other tanks. • can be processed in a simple way • No recycling • Paint or maintenance-free • Can be manufactured in any color • Not magnetic • Light transmittance can be provided • Chemical and combus

Request for a quote

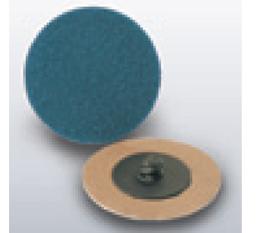

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment. Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quote

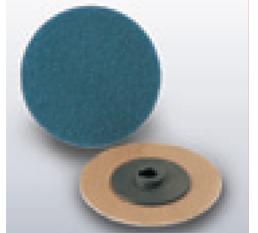

BIBIELLE S.P.A.

Italy

Zirconium discs, Y-weight backing. Main features and benefits: Zirconium ensures highly efficient removal in all applications requiring high operating pressure. Recommended applications: Mould making, manufacture of small-sized tanks and equipment Work surfaces: Stainless steel, alloyed steel, titanium, glass fibre.

Request for a quoteResults for

Pressure moulding - Import exportNumber of results

10 ProductsCountries

Company type