- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process development

Results for

Process development - Import export

YSTRAL GMBH MASCHINENBAU + PROCESSTECHNIK

Germany

Paints and coatings, sealing and insulating materials, coatings, chocolate masses, dairy products, personal care and many other products are produced on process systems from our company. The efficiency and effectiveness of your manufacturing processes can be significantly increased with the help of individually built process plants. Customized process plants are used by our customers worldwide. Container systems, which can be used flexibly at different locations, are available as well as our skidded units, which are completely frame-mounted and automated production units. Recipe control, visualization, weighing, measurement and control technology, containers and piping, CIP systems - all plants are completely assembled in our factory. After a test run under production conditions they are accepted by you. Our technicians are available to you on site for installation, commissioning and service.

Request for a quote

NATROLABS A.S.

Turkey

A full service is provided within the scope of new product development and product improvement activities in our R&D and P&D laboratory for all products manufactured at Natrolabs. Our laboratory, which has the ability to develop products in liquid, capsule, soft capsule, sachet, tablet, effervescent tablet, sublingual tablet, chewable tablet and powder forms, pre-formulation, pilot production laboratory, stability cabins, analytical development laboratory areas and scale-up and process development studies in service.

Request for a quote

DOREY

France

With the new 8311, PFAFF INDUSTRIAL introduces a new generation of ultrasonic welding machines. With more than 30 years experience in rotary ultrasonic welding, the engineers at PFAFF have successfully developed this process even further. In addition to the regulation of speed and welding energy, the new 8311 allows the force measured during welding to be measured and kept constant - a true world first and a quantum leap in textile ultrasonic welding. Adjusting and handling the machine becomes much easier. The process becomes clearer, more reproducible and easier to understand. In short, the machine is taken to a new level.

Request for a quote

PRAXAS B.V.

Netherlands

With the Lascar SGD 70-A DK+ development kit you are able to quickly get started developing advanced user interfaces and panel meters. This kit contains everything you need to get started: an SGD 43-A display, a development board and a USB cable. The development board contains switches, buttons, LEDs and screw terminal connections to quickly and easily test all input and output functions of the PanelPilotACE display. It makes the development process easier and more efficient, allowing you to spend more time designing and less time connecting and testing components.

Request for a quote

PRAXAS B.V.

Netherlands

With the SGD 43-A DK+ development kit you are able to quickly get started developing advanced user interfaces and panel meters. This kit contains everything you need to get started: an SGD 43-A display, a development board and a USB cable. The development board contains switches, buttons, LEDs and screw terminal connections to quickly and easily test all input and output functions of the PanelPilotACE display. It makes the development process easier and more efficient, allowing you to spend more time designing and less time connecting and testing components.

Request for a quote

STEEC

France

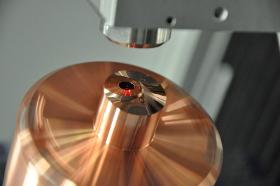

STEEC is able to carry out milling and micro-milling operations on complex mechanical parts with increasingly finer dimensions and increasingly tighter tolerances. STEEC carries out micro-drilling operations to manufacture not only parts but also very high precision electrodes. That enable all spark erosion micro-drilling and countersinking operations to be performed. Equipped with a stock of high-tech machines and leading edge IT tools, such as the Solidworks software, STEEC is capable of meeting special requirements and providing innovative solutions for each of its customers. The experience gained in other high precision machining technologies has enabled STEEC to develop innovative milling processes that are well recognized in the industrial environment.

Request for a quote

CTRA

Tunisia

CTRA produces a wide range of boiler-made equipment for chemical processing, including reactors, columns, decanters, mixers, gas coolers, gas scrubbers, odour scrubbers and absorbers, as well as their internal equipment. All this boilerwork is designed by our departments to meet the dynamic and hydrostatic loads required by the various processes. Thanks to the development and mastery of materials, CTRA is able to design a wide range of boilerwork, up to 6 m in diameter, to withstand the most corrosive fluids, whether they operate in a vacuum or at high pressure, from 50°C to 200°C.

Request for a quote

COLORPLASTICCHEMIE ALBERT SCHLEBERGER GMBH

Germany

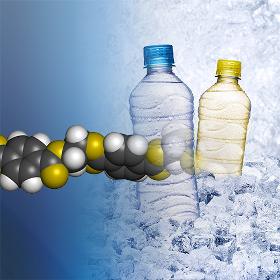

The new alternative to amorphous PET pellets: In an innovative process developed by cpc, the material is directly post-crystallised. In this way, we are continuing the development from discontinuous crystallisation to underwater strand pelletisation and underwater pelletisation to direct post-crystallisation.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

Special purpose machines are our specialty. We are able to adapt our standard machines to your needs within a short time or to develop and build completely new machines for your application. Our extensive know-how allows us to accompany you from process development through the design and detailed construction of a suitable machine to measurement, commissioning and the start of production in your plant. In addition, even maintenance or product adjustments if necessary.

Request for a quote

B + B THERMO-TECHNIK GMBH

Germany

The punctual measuring infrared thermometers are especially suited for precise controlling of industrial production processes, in the research and development and for controlling the function of various devices and plants.

Request for a quote

ISOVOLTA AG

Austria

Prepreg with a modified phenolic resin system specially developed for processing in presses (crushed core) where short processing cycles can only be achieved through higher cure temperatures with lay-ups and de-moulding in presses that are still hot (hot in / hot out).

Request for a quote

BORSIG GMBH

Germany

Reducing energy, saving resources and safe processing have high priority in the chemical and petrochemical industry today. Our advanced liquid separation technologies are targeted to treat hydrocarbon based or solvent containing process streams and provide valuable tools for process intensification. Typically organic liquid streams are processed by conventional thermal unit operations that consume high amounts of energy, operate at high temperatures and/or require additional chemicals for efficient separation. Our membrane based solutions offer potent alternatives or additions for new processes and a valuable tool for the retrofit of existing unit operations. Our product range: - BORSIG Organic solvent nanofiltration - BORSIG Pervaporation - BORSIG Process development services

Request for a quote

EMBRO GMBH

Germany

When it comes to seat heaters, we at Embro think first and foremost of the textile processors of vehicle seats. Because our textile heating elements are in great demand in the automotive industry. They are easy to process, flexible, and kink-resistant. The heat output is individually adapted to the customer’s requirements in the development process and suitably distributed and laid out on the desired surface (wire laying). With the increasing number of electric vehicles being produced, the demand for further heating solutions for the interior area is also rising. Embro heating mats heat the seats and interior via heating elements in the center and side armrests and trim parts. As a developer or engineer in the automotive sector do you need a specific heating element for a product? We are looking forward to your ideas!

Request for a quote

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

INGENERIC GMBH

Germany

The first approach for the development of new processes and the research of scientific effects is the application of standardized laser systems. When the requirements on scientific research advance, they equally rise with regard to the laser systems. For optimum results in scientific research and development, diode lasers with very precise specifications are indispensable. Operating and monitoring the system with defined and fixed parameters such as the power distribution and wavelength is essential for the accurate collection and evaluation of data and will lead to reliable results. Provisioning an outright laser system will further enable scientists to actually focus on their actual research. As complete solution the system can furthermore be directly integrated into the security system, providing a safe operation for your team of experts.

Request for a quote

DRESSLER GROUP

Germany

Two current examples of Dressler Group innovations: Spherical Powder Technology (SPT) and the development of integrated processes. SPT is a process that allows powders to be made out of high-performance polymers that cannot otherwise be pulverised. This opens up completely new kinds of applications, using processes such as 3D printing/additive manufacturing, that were equally impossible before. Meanwhile, integrated processes allow grinding, sieving and dust removal to be carried out in a single operation rather than separate steps, thus saving energy and time.

Request for a quote

KULLEN-KOTI GMBH

Germany

Kullen Koti End, Cup and Bevel brushes give a gleaming finish to oxidised or coated metal surfaces. They are all-rounders in drilling machines, on angle grinders and in machining centres, performing such tasks as removing paint, scale and corrosion. They are also ideal for use in places which are difficult to get at, and were specially developed for the processing of edges and corners.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

POREX TECHNOLOGIES GMBH

Germany

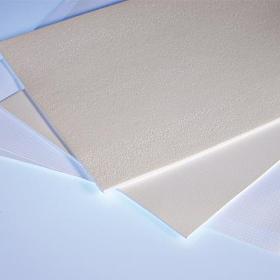

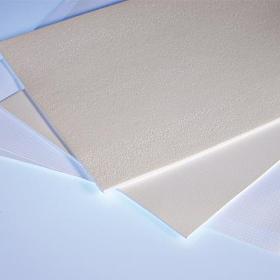

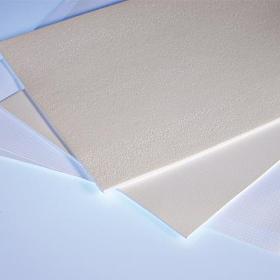

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quote

DIERMEIER ENERGIE GMBH

Germany

Water-miscible premium cooling lubricant Description Castrol Alusol ABF 47 is a boron, amine, formaldehyde releaser and chlorine-free water-miscible high-performance cooling lubricant. It contains a unique additive package that improves machine performance and surface quality, ensures excellent stability and reduces machining costs. Castrol Alusol ABF 47 is suitable for both central systems and individual systems. Application Castrol Alusol ABF 47 was specially developed for processing aluminum alloys. The product can also be used to process low-alloy steels and non-ferrous metals .

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

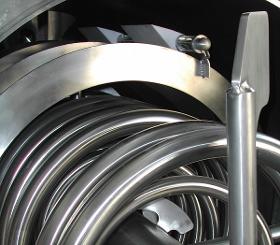

LIPP® Welded Tanks offer the ideal storage solution for a wide variety of media. Tanks are produced by means of an automated welding process specially developed by LIPP® and can be constructed individually in diameter in volumes of 50 to 10,000 m³ according to the application. LIPP® offers a corresponding selection of metallic materials suitable for use with storage media ranging from drinking water and foodstuffs to ethanol or oil. These materials range from a variety of different steel grades to highalloy stainless steels. The automated process meets the highest quality standards. LIPP® Welded Storage Tanks can be produced within a short time, either on site in the open air or inside a building.

Request for a quote

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

An experienced, in-house team of test and analysis specialists stands for the peak of quality – product-specific and exactly as you, the customer, desire it. To ensure quality in serial manufacture early on and guarantee a frictionless start of production, test equipment is incorporated into manufacturing processes and automated production lines. Placement tests, checking the electrical and software functionality, launch tests – depending on your individual requirements and your component, we will develop a test strategy and tune the tests to fit with each other. Our comprehensive test development methodology accelerates processes running all the way to the delivery of your product and reduced testing costs.

Request for a quote

FLOTTWEG SE

Germany

Reliability isn't just a keyword for Flottweg – it expresses the company's philosophy. We want our customers to get results with Flottweg that can't be beat. That requires reliable machines, reliable service, and staff whose passion for perfection shows throughout the manufacturing process. The newly developed Flottweg Z2E brings us a huge step towards that goal. This decanter centrifuge is flexible, maintenance-friendly, and powerful. With its easy-to-open cover, Flottweg makes access to the main components quick and easy, with no need for lifting equipment. Together with another feature – the super deep pond – the Flottweg Z2E highlights the know-how that has gone into this decanter. Top flexibility and quality characterize the Flottweg Z2E, which has been Engineered For Your Success.

Request for a quote

DRESSLER GROUP

Germany

We developed a special process for making fine powder systems and composites from low-viscosity melts. With the patented cryo-spraying process CSP, it has become possible to produce highly sensitive products directly from a hot melt to form a solid powder without after-cooling. The entire spraying process is overlaid with nitrogen and also protects very critical substances against oxidation and thermal stress.

Request for a quote

DRESSLER GROUP

Germany

At our Innovation Lab, we develop entirely new processes when the desired results cannot be achieved with standard solutions. Our customers can practically watch over our shoulder and participate in the process to the extent they choose. The results are then put to the test in the adjacent Technical Centre. Sometimes this opens up whole new business areas for our customers. Getting more than they bargained for – that’s one more thing our customers appreciate.

Request for a quote

EC PLAZA

South Korea

HERID KOLLMAK Protection series Five kinds of newly developed Urethane based products Si, SE, SU BLACK, SU MATT It has been launched at the end of the long research and development process to prevent scratches in life and preserve the car as new as possible. With 100% of TPU based film, it is extremely easy to apply, and maximized effectiveness of softness of the film to shorten application time. Product Specification HERID KOLLMAK is a high performance clear coated aliphatic polyurethane film that is formulated to protect the surface of vehicle from stone chips, abrasion and corrosion. It is one of the best TPU films used for automotive interior materials, and provides superb quality of workmanship. HERID KOLLMAK is easy to apply, and retains painted bodies’ original gloss while resisting yellowing staining. It also offers superior temperature resistance and self-cleaning performance for high durability and easy maintenance.

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

MBW GRUPPE

Germany

"The zinc-nickel process has developed in recent years into a process providing one of the most efficient coatings in surface refinement, and is primarily used where high corrosion resistance at a high temperature load is required. Zinc-nickel alloys with 12-16% nickel content are very temperature-resistant, the higher level of hardness compared to the normal zinc coatings is also a very important property, since the risk of damage is lower. The process is related to the conventional alkaline zinc method, but has excellent durability even without post-treatment. This process is suitable for both barrel and rack goods."

Request for a quote

POREX TECHNOLOGIES GMBH

Germany

Maximize performance of powder-coating systems POREX ® fluidizing sheets help provide a uniform and evenly distributed air supply stream in powder-coating systems in which powder should flow like water. With our special molding process, fluidizing sheets are developed with consistent pore sizes and airflow characteristics. Fluidizing sheet quality and performance is carefully checked using specially designed test devices and procedures, which ensures confidence with every use. To maximize performance, our fluidizing sheets: Deliver uniform powder distribution – Powder flows like water because the sheet provides a uniform distribution of air. Allow full fluidization – Engineered porous sheets maximize the efficiency of powder-coating systems. Ensure consistent system performance – Special molding process establishes evenly distributed pore sizes and airflow properties. Features Consistent pore structure evenly distributes air stream Strong and rigid for maximum service life and...

Request for a quoteResults for

Process development - Import exportNumber of results

162 ProductsCountries

- Germany (80)

- Turkey (13)

- United Kingdom (12)

- China (7)

- Switzerland (7)

- Italy (6)

- Netherlands (6)

- France (4)

- Slovenia (3)

- Ukraine (3)

- Estonia (2)

- South Korea (2)

- Spain (2)

- Tunisia (2)

- Austria (1)

- Belgium (1)

- Brazil (1)

- Canada (1)

- Liechtenstein, Principality of (1)

- Luxembourg (1)

- Oman (1)

- Portugal (1)

- Russia (1)

- Slovakia (1)

- South Africa (1)

- United Arab Emirates (1)

- United States (1)

Company type

Category

- Dustbins, waste bins (9)

- Lubricants, industrial (5)

- Medical laboratories (5)

- Chemical and pharmaceutical industry - machinery and equipment (4)

- Domestic waste treatment (4)

- Gas detectors (4)

- Outsourcing - product development (4)

- Import-export - mechanical engineering (3)

- Plastic material processing (3)

- SMALL METAL PARTS (3)

- Wheels, castors and rollers (3)

- Business Consultancy (2)

- CAD/CAM Computer Assisted Design/Computer Assisted Manufacturing - software (2)

- Filtering equipment and supplies (2)

- Industrial design (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Natural fertilizers (2)

- Petrochemical industry - installations and equipment (2)

- Pharmaceutical industry - machinery and equipment (2)

- Programming and software (2)