- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- production of packaging materials

Results for

Production of packaging materials - Import export

FERPLAST SNC

Italy

MODULAR LINE SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Semi-automatic, angular machines offer maximum packaging flexibility, and a quality product at a competitive price. MODULAR 50S and MODULAR 70, which have recently been updated and revised, can be used to package products using any material, producing highly attractive results. MODULAR LINE uses an electronically controlled sealing system and the very latest safety devices. The lines can be used in automatic or semi-automatic mode, and the operating programs can be customised in order to simplify the packaging process and maximise productivity. MODULAR 50S and MODULAR 70 can also be used with the TUNNEL.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

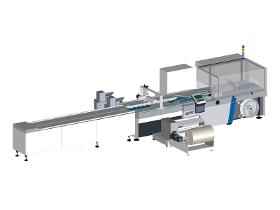

Paper or film? Stay flexible! A single machine can now deliver both film and paper packaging applications. The continuous Form Fill and Seal Machines paper X hybrid are designed for packaging goods in paper or film. A simple changeover ensures you are ready for the new product and the new packaging material. Whether using a chain infeed or infeed conveyor, the machines stand apart through their continuous packaging process – without stop-and-go – maximising efficiencies by ensuring there is no downtime when sealing or glueing. Our paper packaging solutions are available in different versions, depending on how flexible you need to be: - the basic model paper X features paper packaging with overlap on top - the paper X hybrid features paper and film packaging with overlap on top - the paper X hybrid advance features paper and film packaging with overlap on top and side seal

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Atlas SUNTEST XXL+ FD is a large state-of-the-art xenon flatbed instrument. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. XXL+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-30 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. 3x 1700 W air-cooled Xenon Lamps 3000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Measurement and Control of Irradiance 300-400 nm / 340nm or 420nm Measurement and Control of Black Standard (BST); (Black Panel optional) Measurement and Control of Chamber Temperature Display of Diagnostic Messages Storage for 10 user-defined test methods Pre-programmed international standard test method Multilingual User Interface Control Panel tiltable for increased operating comfort Thermal insulation of test chamber and periphery preventing water condensation Temperature control selectable either via CHT (15° * - 70 °C; *with chiller) or via CHT and BST (25° * - 100 °C; *with chiller) simultaneously (dual control) Adapted chiller SunCool XXL+ for testing at low temperatures in the range 15-30°C CHT; detachable for standard weathering testing needs Ultrasonic humidification system for controlled humidity during operation without SunCool Specimen spray system with integrated 60 l water reservoir for spray cycles at 25°C ** - 70°C Static, horizontal exposure area for flat or 3D specimen Test chamber with 5 ° slope for optimum spray water drain Access port ca. 3,0 x 2,5 cm for potential use of additional external sensors inside the test chamber Light cassette including non-ageing aluminium reflector, coated quartz filter and slot for additional optical filters Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) Sliding sample table for easy specimen loading; exposure area (WxD) 74 x 37 cm

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ FD is a premium stand-alone rotating rack xenon instrument with 4000cm2 exposure area. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. Beta+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-50 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. Beta+ FD offers two custom racks - a bottle rack and a packagings rack. Both carry loads up to 20 kg and fit various packaging shapes and sizes. Economic non-aging filters guarantee realistic simulation of all three common light conditions - outdoor Daylight / indoor Daylight / Supermarket light, while a chiller keeps test temperatures on realistic levels even at high irradiance. Programming and monitoring can be done online. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct setting and control of Irradiance (300-400 nm) or (300-800 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Display of Diagnostic Messages Storage for 10 user-defined test methods Multilingual User Interface Test chamber with rotating rack technology; for application-specific specimen racks Thermal insulation of test chamber and periphery preventing water condensation Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window Optional StoreLight filter to simulate supermarket light conditions On-rack XENOSENSIV 300-400 nm or 300-800 nm sensor for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by CHT (10° *- 70°C; *with chiller) or by CHT and BST (25° * - 120°C) simultaneously (dual control) Fan-controlled temperature difference between Chamber and Black Standard Temperature Chiller SunCool Beta+ for extended CHT- and BST-ranges towards lower temperatures UV-protected test chamber window Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Internal memory chip for storing instrument data Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“)

Do you sell or make similar products?

Sign up to europages and have your products listed

MONTA FULFILLMENT

Netherlands

Monta has extensive knowledge of protective packaging materials for your products. Every product requires a specific packaging method so that it will be delivered to your customer in perfect condition. We are also in the advantageous position of being able to purchase high volumes of specific packaging materials at favourable prices. Monta can also package the products in packaging material supplied by the webshop. Moreover, we offer the option of adding your own cards or discount vouchers to the order. This adds a fun, personal touch and/or encourages your customers to make even more purchases from your webshop!

Request for a quote

FACA PACKAGING

Spain

We care about sustainability and that is why Faca has launched 100% recyclable products and ecological packaging (sustainable raw materials).

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

This precisely guided system safely and quickly seals through product residues in the seal area. Narrow seals and reduced head space above the product contents save packaging materials. Operational costs are significantly reduced while the quality of products is ensured. Elements, such as film pusher units, temperature adjustment of weld tools, and special solutions for machines with lateral fold-open equipment, are optionally available.

Request for a quote

FLÖTER VERPACKUNGS-SERVICE GMBH

Germany

If you fill your boxes with paper to secure your goods, you'll send a lot of heavy paper across the country which adds to your freight costs. The paper does not disappear afterwards, the packaging waste remains in full. This is not true for air cushions, as they consist of 99% air and only one percent of film. You’re sending practically nothing but air. Air cushion - a good idea for the environment Packaging with air cushions means the avoidance of transport damage with minimal packaging costs - a great idea for the environment! Particularly with AirWave air cushions from FLOETER. The latest generation of FLOETER production lines is able to produce very thin films down to a thickness of 12μm. This can save many tons of CO2, that would be produced in the production of heavy packaging material. Also, the recycling routes for polyethylenes have long been established. From the resulting plastic residues, new and durable products are being produced through recycling.

Request for a quote

XIAMEN ARABELT TRADING & CONSULTING CO.,LTD

China

At ARABELT, we’re your go-to partner for efficient and cost-effective procurement of paper and packaging products: - Shipping Supplies - Packaging Materials - Paper Products - Packaging Machinery - Labels and Tags - Protective Packaging - Custom Packaging Solutions - Warehouse and Storage Solutions

Request for a quote

PETAINER

United Kingdom

Petainer manufactures a wide range of high-quality PET preform designs for water, carbonated beverages, juices, beer, alcoholic drinks, food and household products. Cost-effective and sustainable, PET preforms are available in virgin and recycled PET materials. We provide end-to-end solutions for fast, economical, technical product development. Our production facilities are equipped with laboratories that offer in-house customer support in critical areas such as: - Design and development of product packaging - Material analysis, physical performance and shelf-life testing - Material research and scanning - Flexible trials with dedicated injection and blow moulding machines - Our experienced team of field-based service technicians can provide you with onsite technical support and training.

Request for a quote

PRODUCTION COMPANY PLATFORMA (PLATFORMEKS LLC)

Russia

Flotoreagent oxal T- is used in manufacture of plasticizers for rubber products and film materials Description: Not stratified, yellow to brown color liquid with a weak smell of ammonia Characteristics: flares up from contact with fire, hot objects, does not create fire or explosion when interacting with oxygen and water. Scope of application: manufacture of plasticizers for rubber products and film materials Type of packaging: Jerry cans, steel barrels, intermediate bulk containers, tank trucks

Request for a quote

ATLANTIC BOOM FOOD

United States

Our frozen meat for export from the USA represents the highest standards of quality, safety, and taste. We take pride in offering a diverse range of premium frozen meat products that meet the demands and preferences of customers around the world. Our frozen meat selection includes various types of meat, such as beef, poultry, and lamb. These meats are sourced from trusted suppliers who adhere to strict regulations and standards for animal welfare, food safety, and sustainability. The frozen meat products undergo a meticulous process to ensure their quality and preservation. The meat is carefully selected, trimmed, and processed in state-of-the-art facilities that prioritize hygiene and quality control. It is then rapidly frozen to lock in freshness, flavor, and nutritional value. Our frozen meat products are packaged in suitable materials that maintain the integrity of the meat during transportation and storage.

CHINAGOODS LLC

United States

Plastic kills our planet and nature. Production of PLA / PBAT biodegradable bags / granules instead of plastic bags is perfect solution to make a big contribution for nature protecting. The production of biodegradable bags requires special extrusion equipment and starch granules as raw materials PLA and PBAT. Due to the increase in delivery costs and increased demand for raw materials, it is more profitable and economically feasible to purchase equipment for the production of raw materials and packages in a complex, thereby reducing production costs. WHY US? - direct purchasing of extrusion production from the plant manufacturer - no intermediary markup - holding auctions with the seller in China - support at all stages of the transaction - comprehensive delivery to any city - warranty and post-warranty support - unique recipe for production - organizing the supply of spare parts and components Contact us to know more details!

Request for a quoteResults for

Production of packaging materials - Import exportNumber of results

16 ProductsCountries

Company type

Category

- Bottles and jars, plastic (2)

- Custom packaging (2)

- Packing and packaging materials, metal (2)

- Chemicals - import-export (1)

- Cosmetics (1)

- Extrusion, plastics - machinery (1)

- Films for packaging (1)

- Meat (1)

- Package sealing machinery (1)

- Packing and packaging - machinery and equipment (1)

- Paper - raw materials (1)

- Sealing and wrapping - machinery and equipment (1)