- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- roll wrapping machine

Results for

Roll wrapping machine - Import export

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO/A ROLL for wrapping carriages (roll container), with manual hooking/cutting of the film and automatic wrapping cycle, limit switches adjustable in height to stop reel holder, adjustable limit switches at the base of the reel holder to start wrapping to the desired height, touch panel display with 3 programs winding, truck driving, foot operated mechanical lock, loading ramp for pallet trucks. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

Wrapping machine with turntable FP ECO ROLL for wrapping carriages (roll container), with hooking / manual cutting of the film and buttons for ascent/descent of the reel, guide carriages, foot operated mechanical lock, loading ramp for pallet trucks, progressive starting device. (Machine CE).

Request for a quote

FERPLAST SNC

Italy

FP 15 SE STRETCH-WRAPPING MACHINE with electronic board and digital keyboard, inverter to control the progressive start and turntable rotation speed, 4 wrapping programs, electromagnetic clutch for film tension control, photocell for automatic reading of the pallet height, manual hook up/cutting of the film, and automatic wrapping cycle (CE-standard).

Request for a quote

FERPLAST SNC

Italy

Place the pallet on the platform, attach the film to the base, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. On requrest we can produce wrapping machines with: Rotary table diameter mm. 1800 - 2000 Electronic balance with load cells Load/ Unload rollers STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product

Request for a quote

FERPLAST SNC

Italy

Semi-automatic wrapping machine mod. FP BOX with rotating table, suitable for wrapping boxes and small packages. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The standard table has the turntable completely smooth. You can request the non-slip rubber coating or different locking systems of the pack. Current promotion: The FPBOX wrapping machine for boxes is supplied with a free inverter that allows the adjustment of the rotation speed of the rotary table from 10 to 20 rpm

Request for a quote

FERPLAST SNC

Italy

Wrapping machine semi-automatic with turntable mod. FP BOX - TIRES, suitable to the winding of tires coupled with internal diameters from 300 mm to 500 mm. The rotation of the table is motorized, activated by the pedal and with adjustable speed; the movement of ascent / descent coil is manual with reel holder counterweighted. The machine is equipped with the compressed air device by drive via lever valve for centering and locking of the wheels, consisting of two jaws which are installed on the expansion of extractable pins. To lock and unlock the tires is sufficient to drive the valve lever. The group expansion is raised by about 150 mm. from the plane table.

Request for a quote

FERPLAST SNC

Italy

Wrapping Machine Mod. FP 15 SE/T with table cut for loading and unloading with pallet, and safety photocell, photocell height sensing pallet, digital panel with 3 programs winding, inverter for soft start, manual lock/cut of the film and automatic wrapping cycle (machine CE). NOTE: the machine is loaded from the side. When ordering, with a surcharge, it is possible to obtain the modification for the front load. UPON REQUEST WE CAN MAKE WITH WRAPPING MACHINES: Rotary table diameter mm. 1800 (pallets up to 1300x1300 mm)Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button. The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet.

Request for a quote

FERPLAST SNC

Italy

Place the pallets (EPAL) using a simple hand pallet truck, attach the film to the base of the pallet, select the wrapping program and press the start button.The machine automatically winding and stops. Cut the film manually. Attention: the pallet must not have the inner crosspieces on the side of the transpallet. STRETCH FILM FOR WRAPPING MACHINES: The film normally used on winding machines is 23 my standard in rolls of approximately 16 kg. With 1 roll of film you are able to wrap an average of 60 pallets. The film is also available in white 30 my, suitable to protect the contents of the pallets from sunlight. The white film is opaque and can be used to hide valuable goods during transport. The type of films supplied by us is of premium quality and is suitable to be used on our machines. We recommend using only top quality film in that it significantly reduces packaging waste and failures due to the use of an unsuitable product.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

TECHNIC MACHINES

Turkey

Rolling Shutter Forming Machine is for manufacturing the roller shutters with different width, thickness and roller shutter forming according to customer’s request. Rolling shutter raw material can be strong steel or such as aluminium as to final customers. The main using area of roller shutters are shops, houses industrial constructions, super markets and other constructions. Design and widths can be change of shutter door forming, also sheet metal thickness can be different according to market target price demand or safety requirements. We design for different thickness and working range of our roller shutter door roll forming machine, also general working width of rolling shutter roll forming will be between 80 to 130 mm, but it can be different according to local markets. Roller Shutter Door Roll Forming Machine Units Coil Decoiler Rolling Shutter Door Forming Unit Roller Shutter Door Punching Unit Rolling Shutter Door Fly Cutting Unit Shutter Stacking Unit

Request for a quote

TECHNIC MACHINES

Turkey

As Technic Machines, we supply all kind of roll forming machines. We have in our portfolio some standard roll former machine lines but also we provide customs solutions for our customers Roll former machine is pretty common machine in metal industry and each work can have small differences because of the local market demand on roll forming shape. We provide exact solution for our customers with different width, thicknesses and shapes of roll forming. We supply for our customers as standard roll form machine, Customs Roll Former Machine Glazed and Step Tile Making Machine Roof Panel Roll Forming Machine Trapezoidal Sheet Roll Forming Machine Corrugated Sheet Roll Forming Machine Rolling Shutter Roll Former Machine Drywall and Gypsum Channel Making Machine Just contact with us for your other roll forming machine request, we will provide customs solution according to your roll former machine research.

Request for a quote

TECHNIC MACHINES

Turkey

Roof panel roll former machine is pretty common almost all countries. Shape of metal roof panel can be different by countries but we provide also different shapes for our customers. Also we can provide different cassette or double layer on our roof panel machine. Roof Panel Roll Forming Machine's Units - Coil Decoiler Machine - Roll Forming Unit - Cutting Shear - Control Panel - Stacking Unit Just contact with us for your request, we will provide the optimum solutions.

Request for a quote

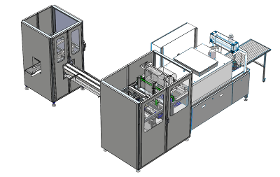

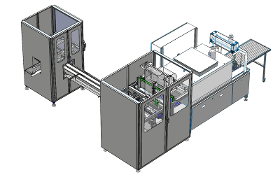

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Compared to the traditional shrink wrapper, our Flow Wrapping machine’s main features are high speed and less material waste, the speed has increased by 2-10 times, and you can save labor costs and time, it is suitable for bowl noodles, milk tea, cup products, frozen products, food boxes, cosmetics, clinker bottles, coil incense, and another shrink packaging. The product that has been packed with the film is sent to the automatic shrinking tunnel through the conveyor and run in the shrinking tunnel through the mesh belt, and the thermal energy efficiency during the operation can achieve the purpose of shrinking. The unit adopts a step-less speed regulation device; and cooperates with an automatic dual temperature controller to control the temperature, through the circulation of hot air, the quality of the shrinkage of the film is more stable and beautiful. The unit has high equipment efficiency, compact structure, reliable operation, low noise, and convenient maintenance.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Four sides horizontal wrap machine fully automatically wrap the products with 2 kinds of film or one kind of film but 2 rolls, consists of a special controller and touch screen for maintenance and control and 4 sets of servos.It is suitable for the packaging of solid sheet items in the pharmaceutical, health care, chemical, light industry, and food industries such as composite film, aluminum plastic film, a pure aluminum film, aluminized film, coated paper, etc., Bodywarmer stick, antipyretic stickers, infusions Heaters, pain relief plasters, medical accessories stickers, game cards, recharge cards, commemorative coins, kiss stickers, temperature measurement stickers, single-piece sanitary napkins, flaky tofu skin, spicy fish fillets, biscuits, etc.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Sleeve Shrink Wrap Machine is made to wrap heavy products with thick film.The finished packaging has two open ends on each side which are referred to as "bullseyes". Standard products packaged with a shrink bundling machine include firewood, canned goods, cases of water bottles, metal products, tool cases, and more. The machine can carry out two-row, three-row, four-row shrink packaging with or without bottom support,like 10 bottles (1 × 10), (2 × 5), 9 bottles (3 × 3), 12 bottles (3 × 4), 15 bottles (3 × 5), 24 bottles (4 × 6). Using worm gear reducer, products feeding and film feeding smooth without jitter. Adopt "Siemens" "PLC" program controller to realize the integration of machine, electricity and gas.Using worm gear reducer, products feeding and film feeding smooth without jitter.Specially designed sealing knife, the sealing line is firm, not cracked, and not easy to stick to the knife.The frequency converter controls the transmission speed.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Side Sealer Shrink Wrap Machine is a fully automatic unmanned operation of an economic side sealing packaging machine, that is widely used in the assembly line of mass production and packaging. It uses an electronic eye to detect products as they pass through on the conveyor. After products pass, a single-sealing arm running perpendicular to the film closes behind the product. As the product continues to pass to the conveyor, a side sealing wheel makes the final seal enclose the product. The advantage of the side seal machine comes from the ability to wrap longer products. The width of the product is limited to the verticle sealing bar, but the length can be as long as needed. A perfect option for shrink wrapping molding, pipes, wood, and other elongated items. The horizontal knife in the sealing part adopts a vertical drive, and the vertical knife adopts a constant temperature side sealer. The sealing line is straight and firm to achieve a beautiful sealing effect.

Do you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

This machine is used for packing candies as well as other solid products with regular shapes such as candies, lollipops,s, etc. Feature: 1. With a three servo touch screen control system. 2. With super plate feeding better and less empty package. 3. Durable structure design prolongs the machine using time and the machine can work separately, is easy to install, and is easy to maintain. 4. With double package rollers and an equipped paper splicer system, the film packaging can be used continuously without a stopped machine. 5. You can choose a vibrator and stainless steel construction for your options. 6. High-speed work stable, low noise, nice package, good seal and the products can keep for a long time.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

MAKREV PACKAGING

Turkey

http://www.makrev.com/urunler.asp?LanguageID=2&cid=2

Request for a quote

PAKMAK AMBALAJ LTD. STI.

Turkey

The Masterplats are the latest range of Turntable Pallet Wrappers from Robopac. Designed using the best features from the Ecoplats with the performance of the Rotoplats. BENEFITS Excellent compromise between economic savings and performance Pallet stabilization Ease of use thanks to the user friendly panel

Request for a quote

YCSMAKINE

Turkey

YCS MAKINE is manufacturing shutter Door roll forming machines using high technology in its facility in Turkey since 2004. We bring together the Turkish engineering discipline with our knowledge and experience of more than 18 years in the metal door profile forming machines and related components, development, and production. We design and produce our Roller shutter roll forming machines based on their efficiency, reliability, life-long-running tooling, and craftsmanship. We are exporting 80% of our machines abroad and our profile forming machines running in more than 30 countries. Know-How and engineering capability for different Countries and customers customized demands. Certificates: CE /ISO 14401:2015/ISO 1002:2018/ISO 9001:2015

Request for a quote

YÜCESAN MACHINE

Turkey

The machine consists of three parts. These; uncoiler, machine, conveyor. Conveyor and uncoiler are included in the machine. Uncoiler 1000 kg. There are two types of uncoilers, with motor and without motor. The machine is produced using 4140 steel molds with 50x56 rocwell hardness. The machine consists of guillotine cutting. Automation system language options; Turkish, English and French. An optional language can be added. The number of stations is 12. However, the number of stations can be changed according to demand. It produces 20-25 meters per minute.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

"Work piece diameter(mm) Ø6 ~ Ø50 Pitch(mm) 0.8P ~ 6.0P, M:0.3 ~ M:1.5 Length of thread rolling(mm) 98MAX Spindle speed 15, 20, 30, 45, 60, 70 r.p.m Thread rolling die(mm) Diameter Ø200MAX Bore Ø70 Length 35,70,100 Keyway 14 X 7 Distance of the rolling spindles(mm) 155 ~ 255 Output (pieces/min) 4 ~ 15 Main power motor 10 HP 6P (7.5 kw) Hydraulic motor 5 HP (3.7 kw) Max rolling pressure 40 TONS Net weight 4050 kgs Gross weight 4450 kgs Overall dimension 1900 x 2300 x 2300 mm Shipping measurement 1800 x 2300 x 2250 mm"

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm) Ø18 ~ Ø60 Axial pitch for ISO threads(mm) 1.0P ~ 6.0P Length of thread rolling(mm) Plunge rolling(In feed):48 Thru feed rolling:no limited Spindle speed 220、350、580、720r.p.m Thread rolling die(mm) Diameter Ø120 Bore Ø40 Length 25,50 Keyway 8 X 4 Distance of the rolling spindles(mm) 105 ~ 190 Output (pieces/min) 4 ~ 25 Swivel of roll-axis ± 3° Main power motor 5HP 6P(3.7kw) Hydraulic motor 3 HP (2.2 kw) Max rolling pressure 12 TONS Net weight (Approx.) 1300 kgs Gross weight (Approx.) 1450 kgs Overall dimension (L x W x H) 1600 mm x 1500 mm x 1600 mm Shipping measurement (L x W x H) 1450 mm x 1400 mm x 1700 mm

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Thread rolling machines are used to produce screws, bolts, and tools. The blank is pressed by thread rolling dies which are attached to the thread rolling machine . The Cam type thread rolling machine is adopted the mechanical cam feed to complete the thread rolling motion, and the precise feed positioning can be ensured. Feature: UM-35 thread rolling machine is suitable to roll standard screws, bicycle pats, automobile arts,.....and various machinery parts. UM-35 thread rolling machine is equipped with the precise work shaft and work gear which keep the steady transmission, and the accuracy of thread profile. UM-35 thread rolling machine is with the precise transmission grinding type gear shape, therefore, noise-free, durable, precisely, and no extra space when transmission are able to be ensured. UM-35 thread rolling of the dove tail-type slide for assuring that jumping, vibration, and wear will not happen during rolling progress.

Request for a quote

KIM UNION INDUSTRIAL CO., LTD.

Taiwan R.O.C.

Work piece diameter(mm)Ø10 ~ Ø75 Axial pitch for ISO threads(mm) 1.0P ~ 10.0P Length of thread rolling(mm) Plunge rolling(In feed):148(75A:200) Thru feed rolling:no limited Spindle speed 20 ~ 50 r.p.m variable speed Thread rolling die(mm) Diameter Ø200(75A=Ø250)MAX Bore Ø70(75A= Ø85) Length 35,70,100,150(75A=70.100.150.200) Keyway 14X7(75A=18X9) Distance of the rolling spindles(mm) 275 ~ 195(75A:300~220) Output (pieces/min) 4 ~ 20 Swivel of roll-axis ± 6° Main power motor 25 HP (18.75 kw)(75A=30HP) Hydraulic motor 7 1/2 HP (5.5 kw)(75A=10HP) Max rolling pressure 60 TONS Net weight (Approx.) 4,700 kgs Gross weight (Approx.) 5,200 kgs Overall dimension (L x W x H) 2,600 mm x 2,400 mm x 2,400 mm Shipping measurement (L x W x H) 2,520 mm x 2,240 mm x 2,230 mm

Request for a quote

SHENZHEN KIMKOO ELECTRONIC & MACHINERY CO.,LTD

United States

Description This pillow roll packing machine with competitive price is special design for latex/memory foam pillow. The rolled pillow can be packed in a box. It is easy to operate and saving cost. If you need machine able to roll package all kinds of pillows, please vist pillow quilt rolling machine. Features 1. Easy to operate, only need one people to operate. 2. High effective 10Seconds/Pcs. 3. Small but it very stable, so it doesn’t waste factory space. 4. Safe and populared. (Now, pillow roll packing is popular in China. Like xiaomi pillow packing way. Details see the pictures)

Request for a quote

SHENZHEN KIMKOO ELECTRONIC & MACHINERY CO.,LTD

United States

Functions: 1. Compressed mattress to an 9:1 ratio of volume 2. Heat sealing 3. Mattress compress into a flat-pack 4. Roll-pack the compressed mattress 5. Adjustable exit diameter Description This new mattress rolling machine is designed for packaging different type of mattresses. It can roll-pack pocket-coil spring/bonnel/foam/latex mattress etc.

Request for a quoteResults for

Roll wrapping machine - Import exportNumber of results

30 ProductsCompany type