- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary fillers

Results for

Rotary fillers - Import export

SYNERLINK

France

Hema NUTRI is dedicated to the particulated and non-particulated sauce and dressings market. It benefits from Hema’s proven expertise built up over several years, in the area of filling complex products for large international groups. It is available in Monobloc configuration with capper or thermosealer. NUTRI filler can also be synchronised to a neck trimmer or a rinser. Combi configuration associates blowing, filling and capping for PET bottles.

Request for a quote

SYNERLINK

France

Mechanically designed, the VOLUF filler is a reliable machine that has proved itself over many years. It is flexible and guarantees easy maintenance and respect of the products to be filled. The VOLUF is available in Stand Alone or Monobloc configuration with a capper or a thermosealer. VOLUF can be also associated with a neck trimmer or a rinser.

Request for a quote

SYNERLINK

France

Hema QCARE is dedicated to the particulated and non-particulated Home and Personal Care market. It benefits from Hema’s proven expertise built up over several years, in the area of filling complex products for large international groups. QCARE is available in Monobloc configuration with capper or Combi associating blowing, filling and capping for PET bottles.

Request for a quote

SYNERLINK

France

Mechanically designed, the Volufill filler is a reliable machine that has proved itself over many years. It is flexible and guarantees easy maintenance and respect of the products to be filled.

Request for a quote

SYNERLINK

France

The Filling method is carefully chosen to match the intrinsic characteristics of your dairy product: its type (e.g. liquid, thick, with or without particulates), what needs to be protected (flavour, vitamins, colour, etc.), its shelf-life (short or long), its sensitivity to external elements (temperature, oxygen). It is a complex equation between relative acidity (pH), the presence of nutrients, presence of O2, sugar content, preserving agents, artificial colourings, stabilisers, which all have an impact on the conservation and bacteriological quality of your dairy product. Our deep understanding of our customers’ dairy product specifications relating to filling has led us to put in place 4 environmental filling families. They mainly depend on the dairy product (weak or high level of acidity), the distribution circuit (cold chain or room temperature) and the expected shelf life of the product.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

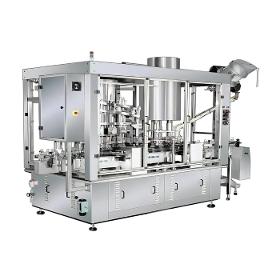

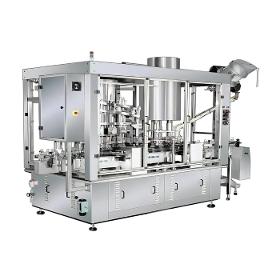

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

HIgh Speed Automatic Rotary Piston Filling Machine is designed for meeting the high capacity packaging demand, Once production requirements exceed the capability of inline piston fillers. it works on same volumetric principle with the inline piston filler,with rotary head, syringe, piston & nozzle. Features: The main frames and construction is made of 304SS Robust, Sanitary design construction with automatic CIP cleaning function Mechanical cam and nozzles design, which ensure the working more stable. Controls platform: Siemens Gears and motors: SEW Germany Pneumatics: Festo Germany or SMC Sensors: Banners “No bottle – no fill” device with anti-breakage safety Pistons entirely in stainless steel, Cylinders in high thickness stainless steel No tool removal of pistons and valve plugs No dead corner, food grade.

Request for a quote

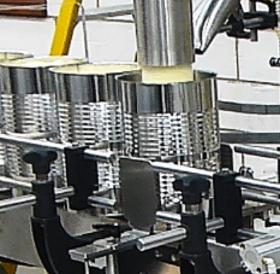

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Innovacera ceramic metering pump is widely used for many famous brand filing machines. We can make customized shapes and sizes of the ceramic filling pump according to clients’ design requests. Product size for reference: Similar Series Products Min Filling Volume: 0.5 ml Similar Series Products Max Filling Volume: 1000 ml Filling accuracy : <=0.5% Product Application: Applicable in quantitative subpackage with high level of hygiene requirement like injection oral liquid etc. Widely applied to pharmaceutical equipment of famous enterprises BOSCH, B+S, IMA, GROENINGER, INOVA company and Trucking Technology, Miaxis, Qianshan, etc. About the shipping cost: Buyer bear the shipping cost and will send it with freight collected.

Request for a quote

SAPLI SOLUTIONS

Spain

Continuous or Intermittent motion highly Accurate Rotary Powder Filler is a suitable solution for a wide range of powdered and granule products to be filled with medium and high production rates. One or more filling stations options, depending on product flow characteristics and a packaging formats. Rotary machines are available with over turrets of 12 to 48 pockets, with outputs up to 400 containers per minute. These can be integrated with gross or tare and gross check-weigher feed-back systems.

Request for a quoteResults for

Rotary fillers - Import exportNumber of results

10 ProductsCountries

Company type