- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- saw-cut parts

Results for

Saw-cut parts - Import export

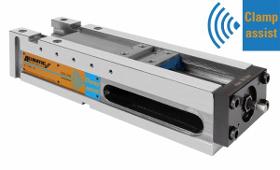

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical use - therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal and saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials and complex geometries to be handled Product features: -To monitor and optimize milling processes -Safety for people and machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used Force translated high-pressure spindle -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal & vertical use - therefore suitable for vertical & horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal & saw cut parts by penetrating hardened & interchangeable grip elements into the work piece -The support jaws safely & cost effectively allow raw part, different types of materials & complex geometries to be handled Product features: -To monitor & optimize milling processes -Safety for people & machines -High flexibility - the modular clamping system combines almost all possibilities of our tried & tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used -Force translated high-pressure spindle. -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal & vertical use - therefore suitable for vertical & horizontal CNC milling machines -Conventional clamping, grip clamping & low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal & saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials & complex geometries to be handled Product features: -To monitor & optimize milling processes -Safety for people & machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K & M can be vertically used -Force translated high-pressure spindle. -Increased power stroke for safe clamping of raw parts -Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Horizontal and vertical use - therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, grip clamping and low tension clapping possible -Titanium 2 K - ideal for use on 5-axis machining centers -Clamping of raw, thermal and saw cut parts by penetrating hardened and interchangeable grip elements into the work piece -The support jaws safely and cost effectively allow raw part, different types of materials and complex geometries to be handled Product features: -To monitor and optimize milling processes -Safety for people and machines -High flexibility - the modular clamping system combines almost all possibilities of our tried and tested models -Titanium 2 M - finely polished sides so that all sides can be used -Titanium 2 K and M can be vertically used -Increased power stroke for safe clamping of raw parts Loss of 8 mm clamping edge in low tension, 3 mm with GRIPP

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -For horizontal & vertical usage-suitable for CNC controlled milling machines & large machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely -Gripper studs suitable for materials with a strength of up toapprox. 1000N/mm² Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -Fully compatible with the accessories of the LC/TC 160 series, for example gripper studs, universal gripper set & pull down sets -Grounded sides so that all sides can be used High-pressure spindle with mech. force amplifier for the safe clamping of raw parts in combination with gripping & pull down spring function -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -TITAN 2 K – ideal for use on five-axis machining centres -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -High-pressure spindle with power intensification. Clamping force does not slacken -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested model -High-pressure spindle with power intensification. -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible -Clamping range of the middle fixed jaw groove: Max clamping width -176 mm

Request for a quote

ALLMATIC-JAKOB SPANNSYSTEME GMBH

Germany

Scope of application: -Can be applied horizontally or vertically – therefore suitable for vertical and horizontal CNC milling machines -Conventional clamping, gripper clamping or pull-down clamping are all possible -Clamping unmachined parts, saw-cut or flame-cut material by penetration of hardened, replaceable gripper elements into the workpiece -With the support jaws, unmachined parts in highly varied materials, or with complex geometries, can be clamped securely and economically. Product features: -High versatility – the modular clamping system combines practically all the possibilities of our tried-and-tested models -The TITAN 2 M is ground an polisched on all sides -High-pressure spindle with power intensification -Enlarged clamping span for secure clamping of unmachined parts -Lost clamping margin 8 mm with pull-down, 3 mm with GRIPPER -Clamping near to neutral axes -Clamping jaws of forerunner are compatible

Request for a quote

PERGEL METAL

Turkey

A circular saw is a tool used in many industries to reshape or cut some raw materials that have different shapes and sizes. As is known, most saws work by hand power. A circular saw is not a classic type of saw. Since it works with electricity, it is extremely advantageous in all respects. Compared to saws with manual use, there is a different operating system. It is placed on a coffee table and cut vertically. In hand-type saws, the floor is not important. Cutting can be done in any desired place. You can get the circular saw service in the highest quality way from our company.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

LATERALLY MOVABLE UNDERTABLE CROSS-CUT SAW / RIP CUT SAW FULLY AUTOMATIC CIRCULAR SAW FOR POSITIONING AND CONTROLLING VIA TOUCHSCREEN WITH LENGTH MEASURING SYSTEM EXENSO COMFORT (PUSHER SYSTEM) Application : Length stop system (pusher operation), revolving table with lateral movement and sawblade inclination via servo - motor for positioning (rip cut, cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Equipment / scope of supply : - Motor rating 12 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - lateral movement of machine table 400 mm with pneumatic brake system - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Cutting height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT - sawblade 650 x 30 x T 54

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 65 V revolving cross cut / rip cut saw Equipment / scope of supply- Cutting heights 90° / 245 mm - 45° / 164 mm - 30° / 113 mm - Machine table with lateral movement approx. 400 mm with pneumatic brake system - Machine hood with lateral PVC protective curtains - pneumatic clamping cylinder left - right - pneumatic cross-cutting operation using two-hand control - electrical saw blade inclination 90 – 30° - Revolving table 0 - 270° - Laser light for cross-cutting - Saw bla de height adjustment via mechanical stop system with scale - TCT saw blade 650 mm, dust extraction spigots 160 / 125 mm - Drive motor 12 kW – direct motor speed 1/min – 3,000 - Saw blade speed 1/min – 3,000

Request for a quote

LALK GMBH &CO. KG

Germany

With the K 4000 Cut-n-Break, you can cut up to 400 mm from one side. It is suitable for flush cutting close to walls and floors as well as for smaller jobs such as window openings. The power cord is routed under the handle, ensuring durability and uninterrupted operation. The one-piece inspection cover and Torx screws make both assembly and maintenance easier

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

Avola GAMA 65 K Revolving Cross Cut Saw for professional applications Technical Equipment Motor rating 8,1 kW/400 Vac-50 Hz, star / delta start sawblade mounted direct on motor shaft Motor speed 3.000 rpm / sawblade speed 3.000 rpm Sawblade height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm Electrical sawblade inclination 90 – 30° – digital readout Revolving table 20° – 160° Two-hand pneumatic cross cutting operation Laser light for cross cutting position TCT-sawblade, dia. 650 x 30 mm x T 54 Dust extraction spigot 125 / 80 mm Options Additional clamping cylinders, horizontal, left-right Brush curtain for safety clamping hood

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

REVOLVING CROSS CUT SAW WITH NC PROGRAMMING SYSTEM GAMA 65 K3 Fully automatic circular saw for positioning and controlling via touchscreen with length measuring system EXENSO COMFORT (Pusher system) Application Length stop system (pusher operation), revolving table and sawblade inclination via servo - motor for positioning ( cross cut, mitre cut or compound mitre cut) of heavy workpieces, i.e. carpenter industry, gluelam industry, log house industry, wooden frame work, solid wood, etc. Technical Equipment : - Motor rating 8,1 kW / 400 Vac-50Hz, star / delta start, direct driven - Motor speed 3.000 rpm - Electrical sawblade inclination 90-30° via servo motor - Laser light for cross cutting - Sawblade height at 90° / 245 mm – 45° / 164 mm – 30° / 113 mm - TCT – sawblade 650 x 30 x T 54 - Dust extraction spigot 125 / 80 mm - Revolving table 20° - 160° - Horizontal material clamping system, right - left - pneumatische Kappvorrichtung über ZweihandSteuerung/vollautomatisch

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

AVOLA stone cutting saws have a distortion-resistant machine frame and a precise cutting wheel bearing. Amply dimensioned ball tracks provide exact and smooth guiding of the table which can be tilted by 45° to the left. The material is cut easily and exactly under the mobile cutting wheel. Special table designs can be supplied on demand at extra cost. AVOLA stone cutting saws are equipped with powerful motors. Motors can be wound for other voltages and frequencies at extra cost. The various materials used in the refractory industry require special machining methods. Although wet operation has become more and more important over the past years, dry cutting is in many cases the only method to be considered for cutting certain materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quote

ROKVELAS, UAB

Lithuania

- Band saw cutting by automatic machines up to 400x400 mm, L12000 mm; - Sheet cutting by plasma by CNC machine up to 50x3000x10000.

Request for a quote

PILANA METAL S.R.O.

Czech Rep.

Bimetal band saw blade with extra wear resistance Application: cutting steels with tensile strength up to 1700 MPa high alloy steel and stainless steel titanium alloys and nickel hard machined materials Characteristics.

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -Comes with a stop rod for repeatable cuts -24 V low voltage system -Emergency stop button -Safety regulations,according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Hassle-free performance

Request for a quote

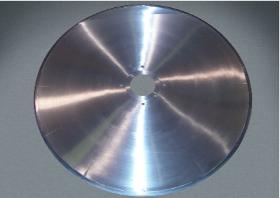

INSTRUMENT I KOMPLEKTUYUSCHIE (LLC)

Russia

This type of disc knives is especially popular on the equipment of the Italian company Gamma Meccanica SpA. main size is D800/d100, suitable both for cutting plates and for trimming edges. The main advantage of this disc is that no abrasive dust is formed while using it.

Request for a quote

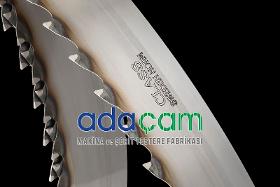

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

A BAND SAW COVERED BY STELLIT WHICH PROVIDES EXCELLENT SURFACE OPTIMUM REGULARITY AND CONTROLLING CUTTING

ADAÇAM MACHINE AND BAND SAW FACTORY

Turkey

A BAND SAW MADE FROM A HIGH QUALITY OF GERMANIAN STEEL C75 S

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage systems -Emergency stop button -Safety regulations, according to CE Standards -Moving saw protection guard -Motor protection kit -Burr-free cutting -Automatic cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts -Process counter -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice -control -Comes with a stop rod for repeatable cuts -Hassle-free performance

Request for a quote

TAŞMAK METAL MACHINERY LTD.

Turkey

-RPM selection for different materials with the 2-speed motor -45° right hand to 45° left hand saw positioning, accurate and precise cutting in two directions -Coolant circulation to remove materials' chips and to cool the disc -Adjustable gear according to the size of the material -24 V low voltage system -Emergency stop button -Moving saw protection guard -Motor protection kit -Burr-free cutting -Precise cutting by centering the material with the double-sided pneumatic vice control -Comes with a stop rod for repeatable cuts

Request for a quoteResults for

Saw-cut parts - Import exportNumber of results

29 ProductsCompany type

Category

- Machine tools - metal machining (8)

- Blades for saws and cutting machines (6)

- Cutting - steels and metals (6)

- Sawing machine tools (5)

- Carpentry - machinery and equipment (1)

- Industrial tools (1)

- Motor mechanics - hand tools, non power (1)

- Sawmills - machinery and equipment (1)

- Woodworking - machinery and equipment (1)