- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- scraper conveyors

Results for

Scraper conveyors - Import export

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK curved scraper is for use on light to heavy conveyor belt systems. The curved solid carbide bar of Curved standard stripper has particularly in the center of the conveyor belt a high wiping effect and relieves the pressure on the outer edges. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the inletof the line for granular products such as peas/flageolets, it removes small waste, sticky waste as well as large waste. Machine mainly consisting of a drum whose perforations in the final section are adapted to the product being treated. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Exit of the products to be treated under the 3rd section of the drum. Recovery and evacuation of waste thanks to a belt conveyor placed inside the drum (except for small waste at the beginning of the machine).

Request for a quote

FEMIA INDUSTRIE

France

Special for spinach.Machine comprised pre washing and washing tanks, pumps that allow for the creation of turbulent flows, some insect trap and propeller to make the leaves plunging in the turbulent bath. Recovery of the water in a settling tray at the outlet of the washer and filtering of the water with a wire rotating drum and its scraper in order to separate the waste. Circulation of water in a closed loop for low water consumption.

Request for a quote

FEMIA INDUSTRIE

France

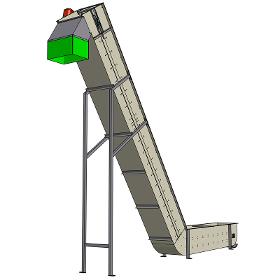

Transfers and lifts the clean product from one piece of equipment to a piece of equipment at a higher level. Several scraper widths are available according to the capacity of the product to be transferred. Adapted to low mass products Adapted to the architecture of the line and to the constraints of the building.

Request for a quote

FEMIA INDUSTRIE

France

Installed at the line infeed of granular products such as peas/flageolet beans, it extracts small size waste and sticky waste as well as large waste. Machine primarily comprised of a drum of which the perforations of the final section are adapted to the product processed. Continuous cleaning of the machine thanks to its system of brushes and scrapers. Products to be processed exit from the 3rd section of the drum. Collection and discharge of waste thanks to a conveyor inside the drum (except for small size waste at the beginning of the machine).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The drum plastic scraper is for use on light to heavy conveyor belt systems. High quality PU segments for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU segments also specially suitable for reversing conveyors belt speeds up to 5 m/s especially for badly damaged belts and PVC belts well suited for use in narrow space conditions limiting damage to the belt longer life expectancy and therefore significant cost savings due to new type of segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure)

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The heated scraper from FTK Förderband Technik Kilian GmbH is equipped with a heater and thermal oil, which prevents the material from freezing on the scraper, both the lower belt and the drum scraper. The heated scraper is particularly suitable for the cold season and at high minus temperatures.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The heat resistant wiper has been specially developed for hot goods and high ambient temperatures, as this wiper is absolutely heat resistant up to 270 degrees. Suitable for drying drums (e.g. in asphalt mixing plants and lime plants).

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK HM inner belt scraper is for use on light to heavy conveyor belt systems. High tech hard metal enables a particularly high time of exposure. The HM inner belt scraper prevents the material from settling in the inner belt between the belt and the drum and so damaging the drum. Belt speeds of up to 2 m/s with the mini model. Belt speeds from 2 m/s with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times.

Request for a quote

INTERNORM KUNSTSTOFFTECHNIK GMBH

Germany

Available with stainless steel axle with suspension for permanent belt contact. We will be happy to assist you with the initial installation. Thanks to an approval according to various EU regulations, we can offer you a top material with the casting polyurethane Intec E for extreme applications in contact with food. Whether for small quantities from 1 or for large-volume components weighing up to 900 kg - Intec E covers the entire range in hardnesses from 45 Shore A to 93 Shore A.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK Förderband Technik Kilian GmbH quick cleaning scraper is a special device to remove the scraper, whether drum scraper or lower belt scraper, from the conveyor belt as quickly as possible and to clean adhering materials. Tools are no longer required. Can be used, for example, in the area of film and paper recycling. Can be carried out by untrained personnel in just a few steps and without tools.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

The FTK master cleaner scraper is for use on light to heavy conveyor belt systems. belt speeds up to 2 m/s with the mini model. belt speeds from 2 m/s upwards with the reinforced model. specially for use with extremely adhering and abrasive materials and damaged belts and having only a minimal installation height. Areas of use various plants, e.g. for sand, gravel, recycling, compost, clay, brick, asphalt mixing plants and in the gypsum, cement and glass industries etc. Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling. The consequences are usually expensive maintenance measures and production down times. The FTK Förderband Technik Kilian belt conveyor scrapers represent a cost effective development in the field of belt cleaning. Due to the flexible mounting arrangements and the gentle but thorough cleaning, the FTK Förderband Technik Kilian belt conveyor scrapers lead

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

FTK primary scrapers for pollution abatement in conveyor belt systems The primary scraper is used for light to heavy conveyor belt systems high tech hard metal for particularly high time of exposure also suitable on spherically rotated drums high flexibility due to PU hard metal segments also specially suitable for reversing conveyors belt speeds up to 5 m/s specially for extremely adherent materials or in difficult or narrow space conditions significantly improved cleaning performance limiting damage to the belt longer life expectancy and therefore significant cost savings due to special segment shape elastic segments with permanently consistent contact pressure with compression springs (for the automatic regulation of the contact pressure) Areas of use sand plants, gravel plants, clay plants, brick plants, asphalt mixing plants and in the gypsum, cement and glass industries etc Any products adhering to the belt reduce the life expectancy of the conveyor due to the heavy soiling.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

No other type of chain is as versatile as conveyor chains and our product range reflects this versatility. Bushing conveyor chains, roller conveyor chains, hollow pin chains, scraper chains, special conveyor chains for the paper industry and rotating chains are just some of the conveyor chains we can supply. Our product range also includes a wide range of special conveyor chains with straight, curved or U-shaped attachments and much more.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used horizontal machining center, year of construction: 2006, extensive manufacturer overhaul in 2021 Product name: MFZ 2-2 Update Used 2-spindle horizontal 5-axis machining center Year of construction: 2006 Extensive manufacturer overhaul 2021 Sinumerik 840D Powerline control Machine dimensions without coolant system and chip conveyor L x W x H approx. 5.10m x 3.05m x 2.8m Weight approx. 20,000 kg (machine without coolant system and accessories) X-axis travel: 450 mm Y-axis travel: 500 mm Z-axis travel: 450 mm Spindle distance: 450 mm Rapid traverse XY Z axis 60,000mm/min 2 x motor milling spindle GMN, version with HSK63 tool holder Drive power (S1/S6) 28 KW (constant) Torque (S1/S6) 63/83 Nm max. speed 16,000 rpm KSM rotary union with electronic leakage monitoring Chip conveyor Knoll (scraper belt conveyor in positioning variant along the machine, ejection height 1,200mm)

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

used, partially overhauled three-spindle, horizontal machining center Product name: MFZ 2-3 Update Machine number 53152 Used 3-spindle horizontal 4-axis machining center Year of construction: 2009 The machine produced until October 2020 Sinumerik 840D Powerline control X-axis travel: 300 mm Y-axis travel: 500 mm Z axis travel: 450 mm Spindle distance: 300 mm Rapid traverse XY Z-axis 60000mm/min 3 motor milling spindles GMN, version with HSK63 tool holder Drive power (S1 / S6) 28 KW (constant) Torque (S1 / S6) 63/83 Nm Maximum speed 16,000 rpm Chip conveyor Knoll (scraper belt conveyor in the setting across the machine) Knoll coolant system with paper belt filter Flushing gun • Complete housing Tool storage (3 x 30 tools) Operating voltage 400V 3N ~ Control voltage 24V DC

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

scraper conveyor profile Coal mining equipment spare parts Xian Huan-Tai has been specialized in Custom heavy castings with machining for mining machinery and cold mining machinery since 1996. Casting process include sand casting, vacuum castings. Produce according to customers’ drawing. Our inspection: 1.Metal testing and analysis, mechanical properties, microstructure, spectrometer and furnace chemical composition analysis. 2.Non-destruction inspection: MPE, LPE, UE and RE 3.Dimension inspection: well experienced inspector team 4.Quality control 5.3rd party inspection 6.Special inspection method agreed by customers like hydraulic, pneumatic test, water tight test etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ERO JOINT .TANALS

France

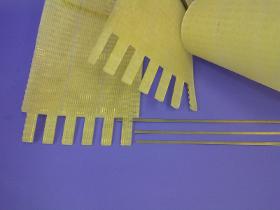

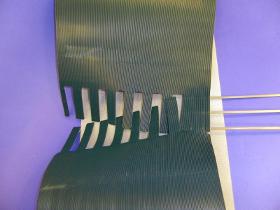

Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The recommended minimum diameter for pulleys is 50mm. The mechanical joint system ERO Joint® WT is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® WT are lasting solutions. The ERO Joint® WT splice shape may be adapted in order to increase the mechanical resistance. ERO Joint® WT is the only one solution of mechanical belt fasteners in wide timing belts. The ERO Joint® WT wide timing belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ERO JOINT .TANALS

France

ADVANTAGES Advantages are a fast and easy installation and assembly. With this new solution of mechanical fastening system, you will save time and optimize your production downtime by reducing the repair time. The mechanical joint system ERO Joint® keeps the minimal diameter of the belt and is compatible with conveyor belts scrapers. Mechanical fastening systems ERO Joint® are lasting solutions. The ERO Joint® splice shape may be adapted in order to increase the mechanical resistance. Mechanical splicing system ERO Joint® are also possible in conveyor belts with sealed tension members (like Gates PosiClean® and FlatClean FC12™) ->More about PosiClean® ERO Joint® belt The ERO Joint® conveyor belts are spliced in our production using a patented process and fitted with the length requested.

Request for a quote

ZIMAS ZINCIR VE MAKINA SAN. TIC. A.S

Turkey

This type of chain is one of the most reliable solutions because the scraper conveyors are one piece. Different sizes and materials are available. It is produced by hot forging method.

Request for a quote

OGE GROUP

Germany

SCRAPER CHAIN CONVEYOR AND APRON

Request for a quote

MAFDEL

France

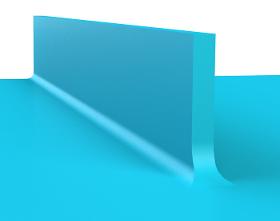

The range of conveyor belts (monomaterial or positively driven) can be equipped with accessories to meet specific needs: profiles, sidewalls, scraper, perforations…

Request for a quoteResults for

Scraper conveyors - Import exportNumber of results

23 ProductsCountries

Company type