- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sealed caps

Results for

Sealed caps - Import export

NORELEM FRANCE

France

Material, version: 1. Sealing cap red Polyamide 66 thermoplastic. 2. Filler sieve black Polypropylene thermoplastic. 3 Flange electro zinc-plated steel. 4. Fastening screws electro zinc-plated steel. 5 Flange seal cork. 6. Chain brass.

Request for a quote

PLAST EMILIA SRL

Italy

We are experts in the production of polyethylene and PVC containers and offer a a wide range of large-scale solutions for caterers, restaurants and discount stores. Polyethylene jars, available with pressure seal caps and screw caps, can be produced in different colors to customize your packaging. Available in different sizes, starting from 500 cc. up to 1,000 cc., all our containers come with one of the caps mentioned above. To complete our offering, we have introduced two large capacity containers of 900 cc and of 1,600 cc. available with a dosing cap or a pressure seal cap. Large polyethylene and PVC containers for restaurants, caterers and discount stores Polythene containers are available with a pressure seal cap or a screw cap, and the caps can also be supplied with a pre-assembled liner for induction sealing. The containers and the caps can be produced in various colors to customize the packaging.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Many of the issues causing poor seals happen upstream, in the filling or capping area: a seal cannot be achieved with a missing cap or a cap with a missing foil. The capper can also cause stalled bottles under the induction coil where caps are loose or partially fitted or the cap is incorrectly fitted or too high. Issues downstream from the sealer can cause containers to back- up under the sealing head. Enercon produces a range of sensors to help ensure that the sealing process is running faultlessly, producing consistent, reliable seals on every container. • Stalled Bottle and Backlog Detector • Missing Foil Sensor • High Cap Detector • Stack light assembly • Variable Speed Conveyor Systems • Spare Parts Kit • IQ/OQ Kit

Request for a quote

FINN-KORKKI OY

Finland

Any existing crowner can be converted to use RipCap or RingCrown caps, with easy and quick change over from one cap type to the other. RingCrown Technology comprises equipment that can be run at the same speed and efficiency as a crowner, up to 60,000 bottles/hour. The equipment consists of a sorting hopper located above the crowner to orientate the cap. The cap chute to move the cap to a cap applier. The cap applier to place the cap to a bottle. RingCrown sealing heads to crimp and seal the cap to the bottle. Finn-Korkki has been designing and manufacturing ring crown cap equipment since 1979. We supply customers with ring crown cap equipment, a supervised installation and operator training when necessary. Thanks to special sealing heads and equipment, metal and plastic bottles can be sealed with ring crown caps. The sealing is at a very low top pressure to prevent the aluminium bottle or plastic bottle from being deformed during sealing.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

A large selection of universal dust caps and threaded plastic caps.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

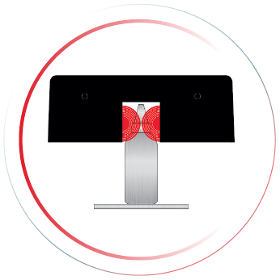

Enercon has two coil design types, each with several variations, to ensure the perfect coil is available for the size and type of your container and cap for your application to deliver perfect, consistent seals. Tunnel coils facilitate higher throughputs than the more traditional flat coils. The Deep Tunnel Coil is used for conical, spouted and other shaped caps. The All-in-One Coil is a variation of the Flat Coil. It is available with the Super Seal™ range and Super Seal™ Touch. This flat sealing head can be pivoted to accommodate various applications. Capable of sealing containers with cap diameters ranging from 20mm to 140mm, it is ideal for packagers who seal a variety of containers and offer the highest degree of sealing versatility. Packagers often don’t realise that the efficiency of the sealing operation depends on the design of the sealing head.

Request for a quote

NEWSUN PV TECHNOLOGY CO.,LTD

China

NSPV Dust cap for solar connectors L03002-001/002 types Features: EPDM insulation material; Flame class for UL94-V0; Used to protect electrical system from dust during panel disconnect; Fits for MC4 connectors.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

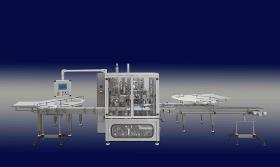

Fully Automatic Tracking Capping Machine Emotion Control is designed base on inline pick and place capping machine, it solve the low capacity of the inline pick and place capping machine, its movement is control by Motion Controller more efficient and accuracy than PLC, the capping heads are moving tracing with the bottles going when capping. it can be equipped with one or two capping heads, capacity is from 40b/m to 70b/m without thinking the size of the bottle and cap (base on 100ml to 5000ml bottle). This machine has the advantage of bottle non-stop working, so after the filling machine, even almost full of liquid inside, the liquid will not splash out when capping. It applies high efficient servo system, including the belt servo, horizontal moving servo, up and down moving servo, and servo capping head system Automatic gripping and capping are completed by the servo motor, and the movement is precise and the speed is fast.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The ROPP capper is the automatic capping machine which is designed to tighten pilfer proof cap for wine bottles, olive oil bottles, drinks bottles etc. It is suitable for φ12-55mm bottle caps (Equipment can be customized according to lid diameter). The automatic operation helps you save labor and reduce production error. The capping machine is a suitable equipment for roll-press-sealing the aluminum caps for the plastic bottle, pet bottle, as well as glass bottle. It processes the screw-press capping for the bottle under the rolling press from hobs, automatically feeding bottle, caps, removing the reverse caps. The capped bottle favors the characteristics like the stable capping effect, convenient uncapping, so that it function as conterfeit and anti-theft.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Press&snap capping machine is used for snapping press type caps, including three main parts: cap feeding system, cap loading system and cap snapping system. It is characterized by its simple structure and high qualification rate. Can be used alone or inline. Linear design makes it suitable for various caps & bottles with good adaptability, widely used for pressing jar cap, plastic bottle cap, can caps, in industries like food, beverages, cosmetics, chemicals,etc. The machine use the straight line into the bottle, automatically arrange caps, sleeving caps ,caps after sleeve and check will go into the gland system by the clamping belt. Due to the lid-cover flat belt design have a drop of slop, the caps after press will become more and more tightly.The machine has simple structure, convenient adjustment, production speed fast, high pass rate, after cap pressing has good performance, suitable for cap pressing of foodstuff, soy sauce, vinegar, vegetable oil’s bottle shape.

Request for a quote

NEWSUN PV TECHNOLOGY CO.,LTD

China

NSPV Dust cap for solar connectors L03001-001/002 types Features: EPDM insulation material; Flame class for UL94-V0; Used to protect electrical system from dust during panel disconnect; Fits for PV4.0 solar connectors.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The Automatic pick and place capping machine is designed and manufactured by shanghai npack automation Equipment co.,ltd, solving the cap feeding problems and increasing the capper working efficient.The cap pick device can be driven by servo motor or a cam splitter for Synchronize working with the filling and capping. It is an ideal bottle capper for the caps which is specially and can not directly feeding on the bottles,such as the Anti-theft caps,Child Proof Caps,Sports Caps/Push-Pull Cap,Spray Caps,Pump caps etc.The whole machine was made with 304SS with dust cover, safety door, one or two capping heads are for optional, the two capping heads max speed can reach 80b/m. For different types of caps, the cap sorting device will be diffirent, we have the vibertor, centrifugal disc and elevator sorting feeder. And the bottle capper equiped with a cap storage hopper elevator for storage caps for long time working,standard one is around 0.5 cubic meters.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

The Super Seal™ Junior manual induction cap sealer offers the benefits of high-quality induction sealing to start-up operations, product validation and short production runs. The Enercon hand-held cap sealers deliver reliable, repeatable induction sealing and feature quality aids such as batch counters and no-foil indicators, which are often only found on inline production machines. Our unique coil design facilitates the sealing of a wide range of caps including flat, sauce dispensing and conical caps, at diameters from 15 – 150mm. Other hand-held devices will only seal flat caps. The quality, reliability, and safety and support of the Super Seal™ Junior is the same as our high-volume inline production machines. Our hand-held machines are virtually maintenance free and seal continuously time after time for many years without fault. • Handheld and portable • Cap size 15-150 mm • Batch and foil counter • Digital timer • Missing foil indicator • 1KW output

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BÜRKLE GMBH

Germany

IBC discharge valve with 90° hose nozzle and sealing cap. The hose can also be closed with the enclosed sealing cap. Hose nozzle external PA Ø 30 mm, suitable for flexible hoses. The IBC discharge valve is a sturdy, high-quality ball valve with a hose connection and connection adapter including seal, for standard thread S 60x6 external or 1" external, designed to fit all commonly used European IBC containers. With the appropriate thread, the discharge valve can also be screwed directly onto the original discharge valve that is already on the IBC tank if the original valve is leaking or faulty. In this way the IBC discharge valve ensures fast and reliable residual emptying of the container with good dosing. The discharge valve is an indispensable accessory to ensure a professional connection of the hose or for filling from your IBC container.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

Available in three models Super Seal™ 300 Super Seal™ 400 Super Seal™ 600 We have built on the proven design of the Super Seal™ range of induction cap sealers, to bring new features to give more value to packagers. The new Super Seal™ compact induction cap sealers are available in three power levels. There are a variety of sealing heads available to optimise sealing performance for your specific applications. •New display simplifies setup, operation & troubleshooting •Local/Remote modes for start/stop & power level •Seals a variety of caps ranging from 20 – 150m •System settings in a single level menu •High efficiency plug-in induction sealing coils to maximise performance and minimise energy costs •Compact and air-cooled •Power supply electronics are housed in an IP55 enclosure •Fully compliant with all UK and European regulations •Fully adjustable stainless-steel stand for different container heights

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

close tolerances and longitudinally welded carrying roller tubes made of S235JR steel in accordance with DIN 2458; deep drawn steel bearing retainers with calibrated bearing seats pressed in from the side and circularly welded, material thickness min. s = 2.00 mm; RAL 3000 red powder coated sheath, coating thickness min. 60 U; 20 mm Ø round steel in accordance with ISO h9; single row radial steel ball bearings in accordance with DIN625 type 6204 with suitable grease filling and cover plates on both sides made of sheet steel C3 bearing clearance. The calculated service life of the ball bearings, assuming belt speed 2m/sec. delivery capacity 200 t/he bulk weight 0.75 t/m³ temperature range 0° C 50° C is 30,000 hours. Steel circlip in accordance with DIN 471 Sealing using double labyrinth seal, incl. suitable grease filling, galvanized, sheet steel sealing cap and plastic rain cap

Request for a quote

NORELEM FRANCE

France

Material: Aluminium. Version: Bright. Flat seal asbestos-free. On request: Cap marked OIL. Drawing reference: 1) flat seal

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 136 Nm/cycle Stroke 25.4 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 41 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating, Rolling Diaphragm Technology, TPU Bellow Energy capacity 20 Nm/cycle Stroke 12.5 mm Hermetically sealed: The shock absorbers from the ACE Protection series PMCN have a compact, perfectly sealed cap as a special feature. This protection bellows, made of TPU (thermoplastic polyurethane), safely encapsulates the proven ACE rolling diaphragm from the outside environment. Aggressive cutting, lubricating and cleaning agents don't stand a chance and the function of the maintenance-free, ready-to-install shock absorber is retained. They are also available in full stainless steel. The PMCN series is a good alternative to the SP type air bleed collar if no compressed air is available on the machine or system. Reliable protection against aggressive fluids, these miniature shock absorbers are the first choice everywhere where conventional dampers wear out too quickly, eg. As in machining centers or other applications of mechanical engineering.

Request for a quote

BÜRKLE GMBH

Germany

Sturdy bottle with sealing eyelets on the screw cap and the bottle. Particularly suited for sending samples. Seals provide increased sample authenticity. Easy to fill due to wide opening. Particularly suitable for viscous media, powder, granules and pastes.

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

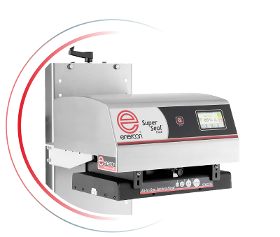

This single coil induction cap sealer offers users increased productivity, an easier set-up and more control. The easy-to-use touch screen is available in multiple languages. The Super Seal™ Touch is our most powerful compact single-coil machine and is designed for production lines running at up to 40 metres per minute. The air-cooled power pack is separate from the induction sealing coil. • Pre-programmed and fully integrated touch screen control for inspection and rejection • Remote start/stop and remote power control (auto start function available) • Password protection with operator lockout • High and low level set power alarm • Recipe management • Internal monitoring of all critical operating data • Diagnostic system information • Internal USB data port – Network connectivity available • Stainless steel IP55 enclosure • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm

Request for a quote

ENERCON INDUSTRIES LTD

United Kingdom

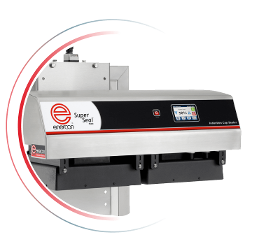

The Super Seal™ Max is the fastest inline sealer on the market, with a dual coil it’s designed for high-speed packaging lines running at up to 100 metres per minute. This dual coil air-cooled induction cap sealer offers increased power and a multi-language touch screen for a simpler operation. It delivers reliable sealing with a diverse operating window that compensates for cap, liner and container tolerance variations. • Multiple language selection • Easy to use touch screen • Supervisory password protection with operator lockout • Recipe management • Internal monitoring of all critical operating data • Container, cap and foil counters available • Local and remote start/stop and power control • Stainless steel IP55 enclosure • Remote network control and monitoring via RS485 or Ethernet • Robust stainless steel fully adjustable stand for different container heights • Seals a variety of caps ranging from 20mm – 150mm • Fully compliant with all CE regulations

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling, sealing and capping machine for viscous products Capacity of the machine: 60 cycles/min. max. 3.600 jars/h Special features: Dosing pump with motorised Adjustment from 0 – 500 ml Heatable hopper with agitatork Output of the filled jars to the cooling tunnel and return to machine for sealing and capping Heatable filling nozzle with recovery system (drip-free) Foil lay-on station (from foil magazines or with punching tool) Sealing station (conduktive system or induction sealing) Capping station

Request for a quote

FILLPACK GMBH & CO. KG

Germany

Filling and closing machine for viscous products Machine performance: 60 cycles/min. max. 3 600 jars/h Special features: Dosing pump with motorised adjustment from 0-500 ml Heatable hopper with agitator Filling nozzle with recovery system (drip-free) Film applicator station (from film magazine or die) Sealing station (conductive system or induction sealing) Capping station

Request for a quoteResults for

Sealed caps - Import exportNumber of results

78 ProductsCountries

Company type

Category

- Drainage systems and equipment (14)

- Food industry - machinery and equipment (8)

- Sealing and wrapping - machinery and equipment (7)

- Stoppers and caps, plastic (4)

- Packing and packaging - machinery and equipment (3)

- Rolling mills - machinery and installations (3)

- Bags, plastic (2)

- Bottles and containers, insulated - camping equipment (2)

- Bottling and filling - machinery and equipment (2)

- Caps, metal (2)

- Ceramics, handicraft (2)

- Magnetic equipment (2)

- Rubber seals (2)

- SMALL METAL PARTS (2)

- Automation - systems and equipment (1)

- Bandages and dressings (1)

- Beverage industry - machinery and equipment (1)

- Cheese-making machinery (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Chemical industry - machinery and equipment (1)