- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silicone injection

Results for

Silicone injection - Import export

SOL-MILLENNIUM

Poland

SOL-Millennium offers a wide range of hypodermic needles with focus on patient comfort. SOL-M™ blister peel-apart packaging allows easy removal of needles. Extra sharp – minimizes patient discomfort. Color-coded hubs – easy gauge identification. Translucent polypropylene hubs – easy flashback confirmation. Stainless steel needle with special silicone lubrication – makes injections more comfortable. Luer Lock- and Luer Slip-compatible. DEHP-, PVC- free, not made with natural rubber latex. PRODUCT BENEFITS • Extra sharp Minimizes patient discomfort. • Color-coded hubs Easy gauge identification. • Translucent polypropylene hubs Easy flashback confirmation. • Stainless steel needle with special silicone lubrication Makes injections more comfortable.

Request for a quote

AMETEK ENGINEERED MEDICAL COMPONENTS

United States

Silicone Molding Liquid Silicone Rubber (LSR) and Silicone Transfer Molding (STM) are widely used in the medical device industry for the production of various medical device components such as catheters, tubing, connectors and handles or grips. The process of LSR molding involves injecting liquid silicone rubber into a mold cavity, often over electrical connections or a circuit board. It is then allowed to cure or solidify into the desired shape.

Request for a quote

REP INTERNATIONAL

France

REP designs and manufactures injection moulding presses optimized for special applications, with one of them being the molding of bladders (open or closed) for the production of tyres. Clamping force from 8,000 to 22,000 kN. https//www.youtube.com/watch?v=7EOOJ7wB_us

Request for a quote

REP INTERNATIONAL

France

V410 LSR Machine features Clamping force 1,600 kN. Size of the platens 430 x 510 mm. Injection volume 1,000 cm³. Machine which is particularly used for the production of flat gaskets as used in fuel cell applications. This machine is available in our showroom « Area 111 » in Corbas (France) to perform your test runs for the injection molding of LSR parts.

Request for a quote

LARKIS SP. Z O.O.

Poland

This mass production technology allows to produce cost efficiently precise parts made by injection molding of silicone LSR, meeting the highest requirements. LSR parts are used in many demanding industries: automotive, electronics, food, medical, packaging, etc. For silicone Automotive Connector Seals read more here.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENBI PLASTICS & SILICONES BV

Netherlands

The use of silicone in products has many advantages: the material is elastic, durable, and resistant to chemicals and high temperatures. As a result, the injection moulding of silicone has many applications, for instance in the medical world. For the injection moulding of silicone we are able to employ machines with a clamping force of between 25 and 100 tons. In this way we can produce units of less than a gram up to about 100 grams, varying in hardness from 10 Shore A up to about 80 Shore A.

Request for a quote

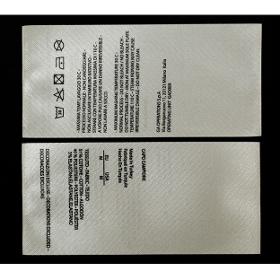

SOIL LABEL

Turkey

Woven labels and washing instructions are textile labels that contain brand name, logo and usage information to identify the manufacturer. They may also have the information with regard to item’s size or its origin. Compared to other label types, their presence on products is permanent. Various types of labels such as cotton, jacquard, plain, satin can be produced by using digital, silicone and injection printing techniques with latest technology.

Request for a quote

SOIL LABEL

Turkey

Woven labels and washing instructions are textile labels that contain brand name, logo and usage information to identify the manufacturer. They may also have the information with regard to item’s size or its origin. Compared to other label types, their presence on products is permanent. Various types of labels such as cotton, jacquard, plain, satin can be produced by using digital, silicone and injection printing techniques with latest technology.

Request for a quote

ENBI PLASTICS & SILICONES BV

Netherlands

Liquid Silicone Rubber (LSR) is a liquid silicon material, which is processed with an injection moulding process. Thanks to its special materials and processing properties, LSR offers unique design and production opportunities for Enbi Plastics. LSR has numerous uses in different industries, including health care, food, automotive, household appliances, and other sectors. For the injection moulding of silicon, Enbi Plastics uses machines with a closing force between 25 and 110 tons. This way we produce products made of components weighing from less than a single gram to approximately 100 grams, and which vary between <10 Shore A to approximately 80 Shore A in hardness, using both 1K and 2K injection moulding processes. Would you like to know more about LSR and how it can benefit your products or components? Our experts at Enbi Plastics love to help you with all your questions about LSR. Feel free to contact one of our specialists today.

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Single component injection moldings Shaping silicone to mold perfect injection parts – This is starlim//sterner's area of expertise. The term single-component injection molding describes the processing of the elastomer substance silicone rubber. This material is processed into small and miniature parts for the auto industry , the life science industry and for the manufacturing industry . Silicone is an elastomer substance with attractive properties. We process exclusively addition and high-temperature curing silicones. Here you find more information on the types of silicone used by starlim//sterner. We can combine your silicone component with a different material, too. Read more on our two component injection molding process. SHARE:

Request for a quote

STARLIM SPRITZGUSS GMBH

Austria

Production starlim//sterner produces single and two component parts made of silicone using fully automated injection molding processes. Production takes place on our sites in Austria (Marchtrenk and Weisskirchen) and in Canada (London/Ontario). In Austria we run more than 200 injection molding, compound and 2K machines and in Canada more than 35. We deploy ENGEL brand machines with a clamping force range of 40 to 300 metric tons. The machines run in shifts: 365 days/year, 24 h. Micro-injection molding is a separate production unit. To meet special requirements of cleanliness/purity and hygiene starlim//sterner has a clean room meeting the following standards: ISO 14644-1 class 7 & 8 and GMP class C and D. Further processing of your products is possible. Several processing automats assemble, punch or slit the products according to customer's requirements. The starlim//sterner production environment represents the state of the art and is certified to meet industry standards. Using s

Request for a quote

AGL GRUP

Turkey

Without any pain and health threat,sizes and shape can be increased quickly,does not include silicone injection or push and filling bras,your butt can recover itself naturally according to the physiological period.Visible changes occur in the hips from the first session.Visible changes occur in the hips from the first session,

Request for a quote

GPMFG

Canada

GPMFG provide efficient, reliable, and high-quality silicone rubber molding solutions for your products.From Tooling/Molds design,manufacturing to molding productiong. Products/Parts Analysis & Optimizing Tooling/Molds Development & Manufacturing Compression Molding Of Solid Silicone Rubber Injection Molding Of Liquid Silicone Rubber Insert Molding Of Silicone Rubber Overmolding Of Silicone Rubber Diverse Post Processes Available Minimum Order Of 1 - 100K+ Parts Get Silicone Parts Within 5 Days Get A Quick Quote In Less Than 12 Hours Complex Elastomer Parts & High Level Of Detail

Request for a quoteResults for

Silicone injection - Import exportNumber of results

14 ProductsCountries

Company type