- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sonotrodes

Results for

Sonotrodes - Import export

DOREY

France

Ultrasonic welding machines of the Seamsonic series combine all the physical advantages of ultrasonic welding with the whole range of technological sewing experience. On the PFAFF 8310 the workpiece is held between the sonotrode and the anvil wheel and welded continuously under pressure. When welding continuously by the ultrasonic method, the material to be welded will be subjected to rapid changing pressure vibrations. The heat develops because of molecular vibrations beneath the material surface, for thin materials within the immediate vicinity of the actual weld. Ultrasonic welding with the Seamsonic is a modern, innovative and economic alternative and complementary to conventional sewing technology. If assembling of laminates, clothing fabrics with high share of polymer and technical nonwovens is required and in particular to get, the use of the Seamsonic is the first choice.

Request for a quote

ATCP PHYSICAL ENGINEERING

Brazil

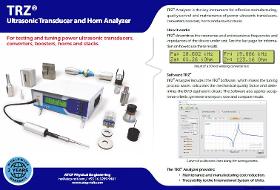

TRZ Analyzer is the key instrument for effective manufacturing, quality control and maintenance of power ultrasonic transducers, converters, boosters, horns and acoustic stacks.TRZ determines the resonance and antiresonance frequencies and impedances of the device under test. TRZ Analyzer includes the TRZ Software, which makes the tuning process easier, calculates the mechanical quality factor and determines the BVD equivalent circuit. The Software also applies acceptance criteria, generate test report, save and compare results.® TRZ Software allows the step-by-step monitoring of frequency and other parameters variation along the machining process, as well as a function of time and temperature.

WEBER ULTRASONICS AG

Germany

Our Sonotrodes are always designed for a specific customer or application using FEM (finite elements method). Usually made from Titanium, we manufacture the correctly shaped blade like arrow heads, sickles, punch or X-Sonotrodes, for each application. For ultrasonic punch applications, we also provide the matching die or counter piece to each punch Sonotrode.

Request for a quote

WEBER ULTRASONICS AG

Germany

Weber uses FEM (finite elements method) to design Cutting Sonotrodes specifically for a customer or an application. These Cutting Sonotrodes are made from high-grade materials like Aluminum alloy, Titanium or sintered steel. Cutting Sonotrodes for the food industry are manufactured to precisely meet the required hygiene standards.

Request for a quote

WEBER ULTRASONICS AG

Germany

The product innovation for continuous cutting: Ultrasonically enhanced cutting tools require less energy and shorter set-up times. They are especially suited for robot applications and use in the food industry.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

In ultrasonic systems, the sonotrode transmits the mechanical vibration of the converter and booster to the relevant workpiece, thus completing the oscillation system. The sonotrode, just as the booster, can additionally increase or decrease the amplitude of the system through a corresponding geometry. Depending on your application and/or the material that needs to be processed, we can design the sonotrode in a way that optimal results will be achieved. soniKKs sonotrodes are usually made of highquality titanium or steel, which is also approved for aerospace. Titanium retains its positive properties even under high temperatures. It has an exceptionally high corrosion resistance and ranks among the light metals thanks to its light weight. We are happy to match our sonotrodes in terms of form and material to your specific needs. Your Advantages “Made in Germany” Made of highquality titanium or steel Suitable for the food and pharmaceutical industry Production of special shapes

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

Integrated compressed air control for sonotrode/converter cooling Optimally suitable for the use of a handwelding gun Defined frequency between 30 kHz and 100 kHz

Request for a quote

KLN ULTRASCHALL AG

Germany

The ultrasonic riveting makes possible an interlocking bonding of two thermoplastics or of thermoplastics with dissimilar materials, e. g. thermoset materials or metals. In this process the sonotrode serves as a re-forming tool. It determines the forming of the riveting pin. During the holding time (cooling phase) the sonotrode serves also as fixation stamp, thus the melted material cools down under pressure.

Request for a quoteResults for

Sonotrodes - Import exportNumber of results

9 ProductsCountries

Company type