- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special gases

Results for

Special gases - Import export

NC MANUFACTURING AND ENGINEERING

Turkey

Engines for combined heat and power plants are operated with different fuels, including hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels. In an exhaust gas heat exchanger, the hot exhaust gas from the CHP engines or CHP gas turbines is cooled, in the process heating water, a water-glycol mixture or thermal oil. This thermal energy can be used in a local or district heating system or for other industrial purposes.

Request for a quote

APROVIS

Germany

What you can expect from APROVIS steam generators: - Efficient steam generation in combined heat and power plants - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Performance areas: 1 to 25 baro, 100 to 25,000 kg/h - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives - Single, double or triple version for operation with one, two or three engines with completely separate exhaust gas sections - The APROVIS Controlling System (ACS) is individually adapted to each project and is delivered in the required language - Access to the ACS using a modem enables easy fine-tuning of the system or remote maintenance for swift support if and when discrepancies occur during operation

Request for a quote

APROVIS

Germany

What you can expect from APROVIS exhaust gas heat exchangers: - Efficient hot water generation in combined heat and power plants - Heating of thermal oil as an energy source - Individual solutions and compact designs - All the main components for the exhaust gas section and gas treatment are combined under one roof: proprietary products developed in-house - Cost-saving and reliable operation of the systems - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Maximum functionality, safety and service - Temperature ranges: up to 600°C on the exhaust gas side or up to more than 1,000°C in the high-temperature range - Certifications: PED 2014/68/EU, ASME Code, EAC - Can be used in all plants with exhaust gases from hydrogen, natural gas, biogas, sewage gas and special gases, plus diesel and other liquid fuels - Geared to international standards and directives

Request for a quote

FLÄKTCOMP SWEDEN AB

Sweden

ATEX fans are fans that are installed in environments where there is a risk that an explosive atmosphere can form. Therefore, these fans need to be designed according to the ATEX directives. Depending on the classification of the environment, internal solutions inside the fan, such as e.g. spark protection in the fan cover or non-sparking materials. While in other cases, EX-rated motors are also required. Explosive gases require special fans. Our factories are certified according to ATEX for the manufacture of fans for Zone 1 and 2 as well as for Zone 21 and 22 containing dust. The design, production and use of fans for explosive media or environment is clearly specified in Europe by standardized directives. To choose the right ATEX fan, one should start from operating data and process design, as well as whether there are any special requirements.

Request for a quote

FILLTECH GMBH

Germany

Filling plants and bottling from a single source Use our services and lay back. At Filltech, we can ensure gas filling services at custom-made aplications maintained and controlled at our premises. Gases for food and industrial applications, noble and special gases and different gas mixtures are filled accurately in different cylinders or containers. CO 2 cylinders for soda If you would like to know what tailor-made systems can achieve andhow many benefits they provide, we like to share our customer cases with you. In the food industry, for example, we cooperated with a soda supplier. We developed and manufactured a fully automatic filling plant. Up to 1,000 cylinders per hour can be drained, flushed and refilled automatically. An integrated leak test, a 100-percent weight loss and the acquisition of all the highest quality padding ensure a high quality process. Special software for monitoring and documenting the production parameters, developed by Filltech, ensures all statutory proc

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BLOWERDOOR GMBH

Germany

Fire safety is one of the areas where the use of BlowerDoor measurements is increasingly gaining in importance. In general, it is server rooms that are measured, where in the case of fire, this is quenched by special extinction gases. High-quality technology can thus be protected against damage from sprinkling or fire water. A prerequisite for the fire protection through extinction gases is an airtight room envelope.With the Minneapolis BlowerDoor measuring system and the FireProtection software, you can easily and accurately determine extinction gas holding times in accordance with ISO 14520 in rooms of angular volume.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

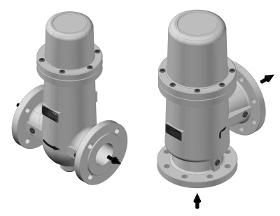

CHARACTERISTICS budget priced short installation length type VZF and ZFG high filtration rate (efficiency) replacable filter cartridges large dust collection area VZF / ZFG dust drain nozzle N3 upstream coarse particle separation 4-way differential pressure connections DVGW certified for all gases according to G260 for non-aggressive special gases many sizes in stock VARIANTS Silumin Cast (VZF/VZEF) Cast Iron (ZFG/ZEFG) Straight Through – VZF/ZFG | DN25 – DN150 Corner Type – VZEF/ZEFG | DN25 – DN100 PN16 | -10 / +70 °C PN16 | -20 / +70 °C PN16 | -40 / +70 °C PN16 | -10 / +150 °C zzgl. TÜV HTB (5 bar g) | -20 / +70°C PN40 | -10 / +70 °C DN25-DN80 PN40 | -20 / +70 °C DN25-DN80 PN40 | -40 / +70 °C DN25-DN80 DNV (maritime) DN25 – DN100, 10 bar g | 0 /+60°C Leaflet: E-5055 Cellular Gas Filter / Type VZF/VZEF/ZFG/ZEFG FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS Efficient dust filtration High deposition rate (efficiency) Filter efficiency tested acc. SAE Fine Test Long service life of the filter elements Upstream coarse particle separation For all gases according to G260 For non-aggressive special gases OPTIONEN Customer-specific design for other regulations (ASME, EN 13445, SVTI, AS1210, PD5500, etc) Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Design temperature up to 250 ° C Customer-specific nozzle arrangement Leaflet (english version in progress): D-5025 Patronenfilter / Typ VPF General Cartridge filters are used to clean gas from dry solid dust particles. The design is carried out as a steel welded construction. FUNCTION The gas flows through the inlet nozzle into the filter housing.

Request for a quote

SETNAG - EXPERT EN ANALYSE D'OXYGENE

France

Measurement of oxygen in combustion gases (specially dedicated to natural gas boilers) Brand : SETNAG ADVANTAGES : No need for reference gas: use of the MicroPoas® Communication: analogue outputs 4-20 mA and RS485 as standard Integrated safety: 3 alarms Control of operating costs, virtually maintenance-free Fast set-up (sensor and electronic system in a single apparatus) Simple and intuitive use MEASUREMENT TECHNIQUE The gases own speed inside the duct enables them to flow freely up to the sensor where they are analysed. They pass through co-circular tubes the length of which can be adapted to the dimensions of the duct. The electronic system collects the temperature and voltage signals from the MicroPoas®, and gives the oxygen concentration. EXEMPLES OF APPLICATIONS Control of combustion in power generation, district heating operations Control of processes... OXYBOX'ATK

Request for a quote

AEROFIL INTERNATIONAL GMBH

Germany

Aero carb is loose granules of activated carbon. This comes in loose form and are used as a blending option for treating various VOCs. They are supplied in 4mm pellet form or in different mesh sizes as per customer requirement. Impregnation of various elements onto this is also done to treat special gases.

Request for a quoteResults for

Special gases - Import exportNumber of results

11 ProductsCountries

Company type