- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electrical components

Results for

Electrical components - Import export

ENDRESS+HAUSER AG

Switzerland

The HAW569 surge arrester is used to protect electronic components in field devices from being destroyed. It ensures that overvoltage surges which occur in signal cables (e.g. 4 to 20 mA), in communication lines of Field buses (HART, PA, FF) and in power lines are safely passed into the ground. The functionality of the electronic component to be protected is not affected as, using the impedance-free connection of the protection unit, interference voltage drops cannot be introduced.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The HAW562 surge arrester is used to protect electronic components from being destroyed by overvoltage. It ensures that overvoltage surges which occur in signal cables (e.g. 4 to 20 mA), in communication lines (fieldbuses) and in power lines are safely passed into the ground. The functionality of the transmitter or the electronics component to be protected is not affected.

Request for a quote

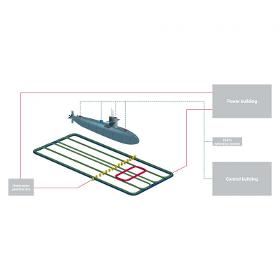

STL SYSTEMS AG

Switzerland

The ODMR (Overrun Deperming and Measurement Range System) is a system dedicated to reduce the magnetic signature of ferromagnetic surface vessels and submarines. It allows a magnetic treatment to control the permanent magnetic signature of the ships in such a way that the ships magnetic signature is minimized. The deperming efficiency depends on the individual class of vessel undergoing treatment, the magnetic behaviour of the steel used, the building process and the magnetic history of the vessel and the operational area with respect to its vertical magnetic field component. The fields of the ODMR are sufficient large to allow a deperming and ranging for all missions required. The ODMR can be designed for all kind of surface vessels and submarines independing of the displacement with maximum length of upto 250 m length, with the dedicated beam depth.

Request for a quote

KOMAX HOLDING AG

Switzerland

The MicroLab 10 enables micrographs to be taken quickly and easily regardless of the location. It covers all relevant processing steps – from cutting and polishing to etching and visualization. The compact carry-case design enables the quality of crimp and splice connections to be assessed with minimum effort and maximum effectiveness. Available in a portable carry-case, the compact MicroLab 10 is designed for contacts and conductors of up to 2.5 mm in diameter. The samples can be quickly clamped in the holder – no re-clamping for all processing steps. The laboratory’s components include autonomous, independent preparation, evaluation and documentation modules. A complete on-site analysis can therefore be performed within a short period of time. A USB digital camera with a microscope is integrated into the lab for visualization purposes and to ensure complete documentation.

Request for a quote

KOMAX HOLDING AG

Switzerland

The bt 288 features two twisting lines, making it the perfect solution for efficient wire set processing – even where large quantities are involved. The Komax bt 288 is based on the proven and tested technology of the bt 188 T. With a second twisting line, this semiautomatic twisting machine offers virtually double the production efficiency without any reduction in processing quality. And with its small footprint, it takes up hardly any space at all. The bt 288 calculates the cut length automatically and – in conjunction with the flat gripper option – can be used to twist three or four wires. The intuitive software (operated via touchscreen) enables you to save the twisting parameters.

Request for a quote

KOMAX HOLDING AG

Switzerland

Seamless quality control is becoming an ever important factor in competition. Micrographs are indispensable in the release of new crimp terminals and tools. The MicroLab 35 micrograph laboratory is a central part of modern quality engineering. MicroLab 35 is designed for the quick creation of micrographs of terminals up to a diameter of 3 mm. The processing time is short thanks to the fully automatic transport system and the reliable technology. The parallel processes allow one micrograph per minute to be created on a continuous basis. The sample is clamped in place quickly with laser support, so the inspection position is determined precisely. There is no re-clamping of samples – the MicroLab 35 cuts and polishes the samples automatically. As soon as the samples arrive at the evaluation unit, they undergo electrolytic cleaning – the micrograph is taken and evaluated.

Request for a quote

KOMAX HOLDING AG

Switzerland

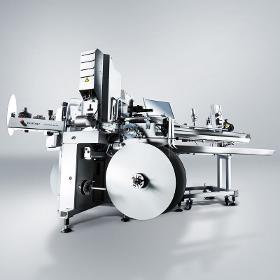

This fully automatic crimping machine stands out from the rest for the high daily productivity it achieves through short changeover times and high availability. This thoroughly tried-and-tested machine is also available with a belt drive. That means optimum force transmission and increased output for long and difficult to process conductors. A supplementary unit that is ideal for a broad processing range. The Komax Gamma 333 PC and PC-B are flexible fully automatic crimping machines offering a variety of efficient processing capabilities. Depending on requirements, these machines can apply two-ended crimp contacts and end sleeves for strands, as well as double crimp connections with three different contacts or seals and sleeves to one end of the cable. Tinning and ink-jet marking are two further options. These models can integrate customer-specific applications like MIL crimping, welding or compaction for a further diversification of production.

Request for a quote

KOMAX HOLDING AG

Switzerland

Consistent high productivity and flexibility with maximum precision are the requirements fully automated wire processing has to meet, both today and in the future. The Alpha 550 – the latest fully automatic wire processing machine for two-sided seal insertion – meets these requirements across the entire spectrum with revolutionary technology. The Alpha 550 can yield crucial competitive advantages with its unmatched unit cost performance, flexible production output and superb quality. The machine comes with an ACD automatic conductor detector as a standard feature.

Request for a quote

KOMAX HOLDING AG

Switzerland

The Alpha 477 fully automatic double crimping machine allows you to process two different wires simultaneously to produce your choice of double crimp or single wires. With four processing stations at the lead termination and two at the trailing end, you have a large number of possible processes at your command. The two wire drives are fitted with highly dynamic AC-servo axes and an integrated anti-slip system. With this sophisticated handling technology, two wires can be fed in parallel and their ends cut to length and terminated in a controlled process. Wires are handled gently throughout. For example, the gripping force exerted on the two wires can be programmed separately and saved for each wire. The two wires are brought together in the double gripper module, where double crimps can be produced either side by side or one above the other.

Request for a quote

KOMAX HOLDING AG

Switzerland

Top quality processing over a uniquely broad range of cross sections. This fully automatic crimping machine excels in simplicity of operation and flexibility. No matter what the task, from double side crimping to twisting, fluxing and tinning, the Gamma 255 carries it out with compelling process control and minimal changeover times. In spite of its compactness, this device has fully integrated quality-monitoring and feed systems as part of its standard equipment. The Komax Gamma 255 is a flexible fully automatic crimping machine for efficient wire processing. It processes cross sections in a range from 0.0123mm²/AWG36 to 2.5mm²/AWG14 in excellent quality. It is compatible with all commercially available applications. It also handles double side crimped wires as short as 20mm.

Request for a quote

KOMAX HOLDING AG

Switzerland

High-performance, even for small cross-sections. Cutting force, high volume output and advanced sensor technology make the Kappa machines the number one choice for automated cutting and stripping, even for smaller wire cross-sections. The machines can be used very efficiently thanks to their simple, intuitive control elements. The Kappa product family stands out thanks to its extremely broad processing range. Its intuitive and simple operation and controls allow you to easily set up even difficult-to-process materials, with extremely fast tool-free changeover to new types of wires. The intuitive TopTouch operating software guides the user through the process logically. During production, operators have maximum transparency thanks to simple adjustment settings for important parameters. This makes the Kappa machines especially intuitive and safe to operate.

Request for a quote

KOMAX HOLDING AG

Switzerland

This fully automatic crimping machine stands out from the rest for the high daily productivity it achieves through short changeover times and high availability. This thoroughly tried-and-tested machine is also available with a belt drive. That means optimum force transmission and increased output for long and difficult to process conductors. A supplementary unit that is ideal for a broad processing range. The Komax Gamma 333 PC and PC-B are flexible fully automatic crimping machines offering a variety of efficient processing capabilities. Depending on requirements, these machines can apply two-ended crimp contacts and end sleeves for strands, as well as double crimp connections with three different contacts or seals and sleeves to one end of the cable. Tinning and ink-jet marking are two further options. These models can integrate customer-specific applications like MIL crimping, welding or compaction for a further diversification of production.

Request for a quote

KOMAX HOLDING AG

Switzerland

MicroLab 30 is designed for creating micrographs of terminals up to a diameter of 10 mm. Processing can be done in less than thirty seconds thanks to the intuitive control system and the optimized arrangement of the cutting and polishing module. An integrated line laser simplifies the determination of the microsection position. The autonomous preparation, evaluation and documentation modules that are part of the lab operate independently of each other and enable a complete on-site analysis. A standardized holder positions the sample without having to re-clamp it. The concentric arrangement of the saw blade and polishing wheel enable an optimum process sequence. Reproducible micrograph preparation is assured by the two step motors that serve as a multi-axial feed control system. The mobile MicroLab 30 requires very minimal maintenance.

Request for a quote

KOMAX HOLDING AG

Switzerland

Alpha 488 S produces fully automatically Twisted-Pairs out of two single bulk wires completely cut-to-length and terminated, with all quality controls included. The modular composition of the system provides superb flexibility. Four processing stations at the wire beginning and two at the wire end offer extensive processing possibilities. The machine layout accommodates up to six processing modules. Wires with cross sections ranging from 2 × 0.22 mm² (AWG 24), optionally from 2 × 1.3 mm² (AWG 26), to 2 × 2.5 mm² (AWG 14), (processing set short open ends up to 2 × 1.0 mm²) can be processed in the highest quality. Alpha488S is available in the versions of four, seven and ten meters. In combination with the Komax crimping modules mci 722 or mci 712 and the Komax seals module mci 765 C as well as with the quick-change systems and the integrated quality monitoring systems Alpha 488 S ensures maximum process reliability and extremely short changeover times.

Request for a quote

KOMAX HOLDING AG

Switzerland

The more value a company adds, the more profitable its operations. The Gamma 263 S is an attractive investment for fully automatic wire processing with a high volume output for many reasons: It requires only minimal space and offers fully developed, durable technology in a variety of versions at an affordable price. The Gamma 263 S is designed for one and two-sided crimping and for one-sided seal insertion. The cross section range extends from 0.13 mm² to 2.5 mm² (AWG26 – AWG13); 4 mm² is also available as an option. Sequential processing can be started fast and easily via TopWin user interface.

Request for a quote

KOMAX HOLDING AG

Switzerland

Seamless quality control is becoming an ever important factor in competition. Micrographs are indispensable in the release of new crimp terminals and tools. The highly flexible and modular MicroLab 55 micrograph laboratory is a central part of modern quality engineering. The MicroLab 55 micrograph laboratory is designed for the most versatile application ranges and is ideally suited for this purpose. It enables micrographs to be produced for all types of crimps available on the market – both transverse section and longitudinal section. The above applies also to products such as PCBs or housings from outside the automotive sector. Extremely short processing times can be achieved thanks to the optimum arrangement of the individual modules. Reproducible sample preparation is guaranteed to be perfect because the sample does not have to be re-clamped between the individual processing steps.

Request for a quote

KOMAX HOLDING AG

Switzerland

You can mount up to five processing modules on the Alpha 355 S. In spite of its compactness, it offers excellent accessibility. Along with the most frequent standard processes of crimping and seal loading, you can obtain a large variety of processing modules such as: fitting with insulating sleeves, ferrules and ultrasonic or resistance welding modules. You can integrate customer-specific processing stations easily with the ultra-flexible TopWin software.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KOMAX HOLDING AG

Switzerland

The Komax Alpha 355 is designed for one and two-sided crimping and seal loading. It even handles double-crimp connections involving varying lengths and the same wire types without any problem. The ultra-precise dual-channel blade system allows for a large range of wire sizes without blade changes.

Request for a quote

KOMAX HOLDING AG

Switzerland

Coaxial connectors require especially precise processing of the conductors: The Cosmic 48R and 48RX are the ideal tools for meeting the quality requirements of connector assembly specifications. The Cosmic 48R processes coaxial, triaxial and other multi-layered cables in up to 9 steps. The Cosmic 48RX is optimised for the stripping of semi-flexible coaxial cables. The Cosmic 48R and 48RX stripping machines are ideal for processing round, multilayered cables. Cuts into coaxial and triaxial cables are made precisely over the entire circumference. The cut parameters can be individually optimised. The Cosmic 48RX is specially designed for semi-flexible coaxial cables. The optimised blade geometry ensures great cut performance even in the processing of tinned outside conductors.

Request for a quote

KOMAX HOLDING AG

Switzerland

The machines in the Cosmic 60 series are portable, semiautomatic jacket and wire stripping machines with rotating blades and a high pull-off force. Operation is unbelievably easy thanks to the analogue settings and the release sensor. These all-purpose machines are operated electrically so they can be used everywhere. The machines process conductors with outside diameters ranging from 2.5 to 10 mm or 11 to 18 mm depending on the model, i.e. they strip single conductors and jackets of multi-conductor cables. The portable machines can be used anywhere a power socket is available. The machines in the Cosmic 60 series are ideal for a highly diverse products made in small to medium quantities.

Request for a quote

KOMAX HOLDING AG

Switzerland

Wire processing today involves a large mix of products as requirements are becoming ever more difficult. The Mira 230 from Komax is the answer to this situation. It delivers an extraordinarily wide range of applications, simple handling and increased productivity. With special functions and its article library, the Mira 230 achieves a high level of reproducible quality. Its ability for sequence makes it the first choice for multi-conductor processing. Thanks to its robust and sturdy construction, the Mira 230 has an extraordinary processing range (0.03 – 8 mm², AWG 32 – 8). With a high level of stripping force, it can process wires with hard insulation. It has special capabilities that go beyond stripping and shortening/trimming, allowing it to handle the most demanding tasks.

Request for a quote

KOMAX HOLDING AG

Switzerland

Wire Processing to the Most Exacting Standards - Great Versatility Without Conversion. The Alpha 433 fully automatic crimping machine is based on state of the art technology and is designed for processing single conductors as well as double crimp connections. The Alpha 433 models are unsurpassed in their flexibility. Seal loading on one or both wire ends, various terminals and double crimp connections of different lengths and the same wires can be processed without difficulty. Teamed up with Komax MCI peripheral devices, the Alpha 433 is a very compact system offering optimum accessibility and ultra short conversion times.

Request for a quote

KOMAX HOLDING AG

Switzerland

Superb twisting quality and high speed – these are the hallmarks of the bt 188 T semiautomatic twisting machine. It is also easy to operate, attractively priced and guarantee fantastic performance. When combined with the new optional spot taping unit, the bt 188 T binds both wire ends using cloth or PVC tape. The bt 188 T is capable of twisting two to four wires with excellent results. The parameters can be adjusted as required, which the machine then uses to automatically calculate the required cut length. For example, you can vary the final twisted length, the pitch length, the wire cross section, the outer wire diameter and the open ends. This minimizes the amount of test material consumed when setting up a new product and ensures that everything is ready for production in no time. The intuitive TopTouch user interface makes the system extremely easy to work with. New products can be programmed and existing ones loaded quick and simple. Up to 1200 different articles can be stored.

Request for a quote

KOMAX HOLDING AG

Switzerland

The rotating blade heads of the Cosmic 927 series provide the perfect solution for processing demanding insulation. Each model in the series has a specific area of application: The Cosmic 927R processes a large range of insulation materials. The 927RX shows its true strength with thin or bonded types of insulation. The 927RX-WL accommodates the biggest stripping length. The stripping machines process conductors with outside diameters of 0.25 to 5.3 mm or a cross section of 0.013 to 6 mm² (AWG 36 to 10). The machines can be used for full and partial pull-off on individual conductors or on inner conductors of multi-core cables. Cosmic 927R: This model has a rotating blade head featuring two blades. It processes a large range of insulation. The Cosmic 927R is especially suited to handling a great diversity of products made in small to medium quantities.

Request for a quote

KOMAX HOLDING AG

Switzerland

With its extra large mounting surface, the Alpha 356 has room for up to seven processing modules. This machine is ideal if you need increased flexibility or have complex processes. Along with the most frequent standard processes of crimping and seal loading, you can obtain a large variety of processing modules such as: fluxing/tinning, twisting the ends of wires, fitting with insulating sleeves and crimping modules for the widest variety of contacts types, ultrasonic or resistance welding modules. You can integrate customer-specific processing stations easily with the ultra-flexible TopWin software.

Request for a quote

STL SYSTEMS AG

Switzerland

Measurement of magnetic and electrical signals with STL's unique 26 bit ADC's For measuring electric and magnetic fields the STL's unique 26 bit ADC pioneers works in an underwater system. In addition to deployment and recovery the chain configuration by a single cable used for power and data transmission uses three or more sensors platforms are fully connected to the base station. Environmental and pressure sensors use an ultra low noise isolation preamplifier, and the analogue sensor front end is formed by 3 pairs of UEP Carbon electrodes. The 26-bit analogue to digital converter is what the digital part is based on with a novel high end performance. Geometry compensated signal output through the consequent digital signal processing provides temperature. To achieve the software alignment the tilt sensors are used to achieve the precise settings with a pair of high resolution electric field vector components.

Request for a quote

DELTA LINE SA

Switzerland

Delta Line has given rise to a motor drive system that redefines the boundaries of size and performance. Pegasus and Hercules, each measuring a mere 39x39mm and weighing 24g, are engineered to perfection, offering an enticing blend of advantages that makes them unique in today’s competitive landscapes. Key Advantages: -High Power in Small Package: despite their diminutive size, Pegasus and Hercules deliver impressive performance. With a supply of 12÷36VDC, they can generate a Phase Current of up to 2A rms, making them ideal for a wide range of applications where space is at a premium. -Versatile Communication Fieldbus: What truly sets these motor drives apart is their compatibility with an array of communication fieldbuses, providing unmatched flexibility. With options like RS485 ModBus RTU, CANopen, EtherCAT, Ethernet ModBus TCP, Profinet, PowerLink, IOLink and EtherNet/IP, engineers can choose the ideal communication protocol to suit their specific project requirements.

Request for a quote

DELTA LINE SA

Switzerland

The Delta Line Phoenix Drive product family is the next generation of highly integrated motor control solutions. By processing all real-time critical functions within the drive, the Phoenix Drive minimizes communication traffic, reduces controller dimensions and decreases the overall system cost. It also provides axis synchronization, making the Phoenix Drive a cost-effective integrated motion controller. The Phoenix Drive uses EtherCAT high speed communication protocol and is available in two configurations: B100 and B500. Both configurations include system protections such as over current, over and under voltage, overheating, phase-to-phase shorts and ground shorts. These drives control BLDC motors with both 5V encoders and hall effect sensors. The B500 Controller includes brake output of 1.3A and STO (Safe Torque Off).

Request for a quoteResults for

Electrical components - Import exportNumber of results

29 ProductsCountries

Company type