- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- telescopic rails

Results for

Telescopic rails - Import export

SCHOCK GROUP

Germany

Telescopic Rail 57.5 x 16 mm, Galvanized Steel, Standard Length 1100 mm, Load Capacity up to 70 kg per pair Full Extension Ball Bearing Guide Load Capacity up to 70 kg per pair Standard Rail Length 1100 mm Manufactured in the European Union The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 45 x 12.7 mm, Galvanized Steel, Standard Lengths up to 600 mm, Load Capacity up to 40 kg per pair Full Extension Ball Bearing Guide Load Capacity up to 40 kg per pair Standard Rail Length up to 600 mm Separable Inner Rail The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quote

ROLLON GMBH

Germany

High load capacity and reduced deflection telescopic rails with caged balls bearings. The telescopic guides have optimal running properties due to inductively hardened raceways. TELESCOPIC RAIL linear slides exhibit little deflection while under very heavy loads, even when fully extended. Telescopic guides come in eight different series (DS, DSE, DSC, DE, DBN, DMS, ASN, DRT) Torsionally rigid intermediate elements with S-shaped, double-T, or squared sections Over-extending, full or partial telescopic strokes are available In the DMS63 Series the supported load can reach 2,000kg per pair. Extremely low deflection and smoothness of movement even in high load, 24/7 applications Some Series can be locked in the closed position Special versions and strokes available upon request The Telescopic Rail product family includes full or partial extraction telescopic rails, and consists of eight (8) different sizes. The deflection resistant central components are available in the S, double T...

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 57.5 x 17.5 mm, galvanized steel, standard lengths up to 750 mm, load capacity up to 80 kg per pair. This telescopic rail from the Schock Group is designed for over-extension with a 100%+ extension range, making it ideal for applications where full access to the drawer or component is necessary. It is made from galvanized steel and offers a load capacity of up to 80 kg per pair, making it suitable for heavy-duty applications. Key Features: Telescopic Rail Type: Over-extension Material: Galvanized steel Standard Lengths: Up to 750 mm Load Capacity: Up to 80 kg per pair Locking Mechanism: Included Manufactured in the European Union Schock Group has over 40 years of experience in designing and manufacturing ball-bearing telescopic rails for linear motion technology. Their telescopic rails are known for their smooth and quiet operation, even under high loads, as well as their reliability and long service life without the need for maintenance.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball-bearing telescopic rails and linear guidance systems for decades. SCHOCK telescopic rails are known for their precision, high load capacities, and long lifespan. Key features of SCHOCK telescopic rails include: Excellent running properties High operational reliability Long lifespan without maintenance Custom connection options Based on individual customer requirements, we develop and manufacture telescopic rails as partial extensions, full extensions, or over-extensions. In collaborative project planning with our customers, we define the product requirements for the telescopic rails. Our customers benefit from a wide selection of rail profiles, mounting systems, comfort features, and high-quality surface finishes, such as SCHOCK powder coating. We supply powder-coated telescopic rails in any desired RAL color, offering you unique design possibilities.

Request for a quote

SCHOCK GROUP

Germany

Telescopic rail 27.2 x 20 mm, stainless steel, standard lengths up to 600 mm, load capacity up to 35 kg per pair Ball bearing over-extension Load capacity up to 35 kg per pair Standard rail length up to 600 mm Closed end stop Operating temperature up to +200°C Manufactured in the European Union For over 40 years, the Schock Group has been developing and manufacturing ball bearing telescopic rails for linear motion technology. The advantageous physical properties of ball bearing guidance form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under high load High functional reliability Long service life without maintenance

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 37.5 x 13 mm, Galvanized Steel, Standard Lengths up to 473 mm, Load Capacity up to 35 kg per pair Partial Extension Ball Bearing Guide with Double-Sided Extension (70-80%) Load Capacity up to 35 kg per pair Standard Rail Length up to 473 mm Manufactured in the European Union The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry,

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 53 x 19 mm, Stainless Steel, Standard Length 500 mm, Load Capacity up to 120 kg per pair Full Extension Ball Bearing Guide Load Capacity up to 120 kg per pair Standard Rail Length 500 mm The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quote

SCHOCK GROUP

Germany

T Telescopic Rail 27.2 x 20 mm, Galvanized Steel, Standard Length 310 mm, Load Capacity up to 20 kg per pair Over-extension Ball Bearing Guide Load Capacity up to 20 kg per pair Standard Rail Length 310 mm With Locking Mechanism Manufactured in the European Union The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball bearing telescopic rails and linear slide systems for decades. Our products impress with their precision, high load ratings and long service life.

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 27.2 x 10 mm, Galvanized Steel, Standard Lengths up to 470 mm, Load Capacity up to 15 kg per pair Partial Extension Ball Bearing Guide Load Capacity up to 15 kg per pair Standard Rail Length up to 470 mm Manufactured in the European Union The Schock Group has been developing and manufacturing ball-bearing telescopic rails for linear motion technology for over 40 years. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under heavy load. High operational reliability Long lifespan without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH from stock, and they can be ordered from a quantity of one piece. Custom solutions are available from Schock Metall on a project-specific basis. We welcome your project inquiry, including your annual requirement and expected start date for production.

Request for a quote

RMZ OFIS

Turkey

It can be used for both hanging file and separator file drawers have plastic roller There is a name tag on each drawer It has Central locking system painted with hight quality electrostatic powder paint

Request for a quote

RMZ OFIS

Turkey

It can be used for both hanging file and separator file drawers have plastic roller There is a name tag on each drawer It has Central locking system painted with hight quality electrostatic powder paint

Request for a quote

RMZ OFIS

Turkey

It can be used for both hanging file and separator file drawers have plastic roller There is a name tag on each drawer It has Central locking system painted with hight quality electrostatic powder paint

Request for a quote

ROLLON GMBH

Germany

Light Rail product line includes full or partial extension lightweight telescopic guides. Optional locking mechanism for open or closed positions Various designs, maximum stroke 1,100mm Telescopic extraction up to 105% of the closed slide length The Light Rail product family includes lightweight telescopic rails to be used in environments allowing only reduced weight components. Smooth and quiet operation is ensured even with heavy loads. Elastic shock absorption avoids permanent distortion. The self-cleaning raceways mounted on the Light Rail telescopic rails ensure safe operation and less frequent maintenance. Main fields of application for Light Rail extractable telescopic rails: Food & Beverage Building & Furniture

Request for a quote

SCHOCK GROUP

Germany

Telescopic Rail 35.2 x 19 mm, Galvanized Steel, Standard Lengths up to 660 mm, Load Capacity up to 52 kg per Pair Ball Bearing Over-extension Load Capacity up to 52 kg per Pair Standard Rail Length up to 660 mm Separable Inner Rail Locking in Open Position Closed End Stop Manufactured in the European Union For over 40 years, Schock Group has been developing and manufacturing ball bearing telescopic rails for linear motion technology. The advantageous physical properties of ball bearing guides form the basis for the performance of Schock telescopic rails: Smooth and quiet operation, even under high loads. High functional reliability Long service life without maintenance Standard items in the specified lengths are available from our distribution partner SToxxparts GmbH in stock and from a quantity of one piece upwards.

Request for a quote

SCHOCK GROUP

Germany

Cold-drawn heavy-duty rails offer exceptionally high load-bearing capacity and stiffness. In our eShop, you can find partial extensions, full extensions, and over-extensions up to 3000 mm in length and with a load capacity of up to 2400 kg. Cold-drawn heavy-duty telescopic extension rails are suitable for extreme loads and stresses. The precision-machined ball tracks ensure accuracy and provide excellent shock and vibration resistance. Therefore, these telescopic rail models are well-suited for demanding tasks in machinery manufacturing, the military sector, special vehicle construction, and heavy-duty shelving. Due to their extreme strength, these telescopic rails are particularly resistant to lateral forces, making them an excellent choice for dynamic and motorized applications, especially at very large lengths. They can also be used at high temperatures since no plastic parts are used.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROLLON GMBH

Germany

Sturdy and practical galvanized or stainless steel linear rails with radial ball bearing sliders. The X-Rail is a family of linear guides with radial ball bearing sliders for applications requiring cost efficiency and high resistance to corrosion. The shaped raceway rail, the flat raceway rail and the telescopic rail are available in stainless steel or galvanized sheet metal. With the T + U configuration, the X-Rail system can compensate for any axial misalignment in parallelism of the mounting surfaces. Three rail width sizes: 20mm, 30mm and 45mm Standard rail lengths up to 3,120mm; different lengths upon request Low coefficient of friction Combination of T and U rails for self-aligning bearing applications Easily adjustable slider preload Polymer based wipers available for added roller bearing protection (available on for the thin body style slider) High temperature resistance up to 120°C/250°F The stainless steel X-Rail linear guide version is corrosion resistant, and ensures...

Request for a quote

ROLLON GMBH

Germany

The Hegra Rail family includes various telescopic guide profiles with ball cage capable of handling high loads up to 20 kN per pair, overextensions up to 200% of the length of the guide in closed position and available in different materials such as steel, aluminium or stainless steel AISI 304 and AISI 316. The main features of the Hegra Rail telescopic guides: handling of heavy loads combined with minimal bending profiles with 1, 2 or 3 moving elements for extensions up to 200% available in different materials: steel, aluminium, stainless steel AISI 304 and AISI 316 high rigidity and moment of inertia with thin sections fluid noiseless operation long working life extremely reliable The Hegra Rail family of telescopic guides includes five product categories: partial and full extensions, overextensions, heavy loads and S-sections. Telescopic guides for partial extensions,Telescopic guides for full extensions,Telescopic guides for overextensions,Telescopic guides for heavy loads

Request for a quote

IGUS® GMBH

Germany

DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism Completely lubricant-free linear extensions in continuous stroke lengths of 100mm to 600mm - maximum pulled-out length: 1200mm. The telescopic systems consist of anodized aluminum guide rails and a gliding block made of the proven iglidur material. By the incompounded solid lubricants, iglidur tribopolymers enable dry operation in every application. The advantage - besides being maintenance-free - is the carefree use in clean hygienic environments. No oil or fat can be transmitted to other products, clothing or people. Applications even in cleanroom air showers were already implemented. But the dry operation also has advantages in the dirt accumulation area. Dirt particles do not stick to the guide and do not become a sticky mass. As an option, all telescopic guides can be delivered with a detent in start-medium-end position. Requirements for individually positioned locking positions can be met. Detailed view: DryLin® telescopic rail in a guard door adjustment. DryLin® telescopic rails Total extensions Partial extensions Over-extensions DryLin® telescopic rails DryLin® telescopic rails with locking function Detent in start, medium and end position Freely selectable locking position DryLin® telescope - wth locking mechanism

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

AZ MACHINERY

France

Designed for use with 3 and 4 wheel forklift trucks. Electro-hydraulic lifting, telescopic lip Side safety rails 24cm high, retractable Hot-dip galvanized grating non-slip running surface IP65 control panels Applications: The EASY-ST model is very popular with logisticians and industrialists, it allows you to integrate your loading ramps in the pit, thus allowing the optimization of circulation spaces.

Request for a quote

AZ MACHINERY

France

Designed for use with 3 and 4 wheel forklift trucks. Electro-hydraulic lifting, telescopic lip Side safety rails 24cm high, retractable Hot-dip galvanized grating non-slip running surface IP65 control panels Applications: The EASY-ST model is very popular with logisticians and industrialists, it allows you to integrate your loading ramps in the pit, thus allowing the optimization of circulation spaces.

Request for a quote

AZ MACHINERY

France

Designed for use with 3 and 4 wheel forklift trucks. Electro-hydraulic lifting, telescopic lip Side safety rails 24cm high, retractable Hot-dip galvanized grating non-slip running surface IP65 control panels Applications: The EASY-ST model is very popular with logisticians and industrialists, it allows you to integrate your loading ramps in the pit, thus allowing the optimization of circulation spaces.

Request for a quote

AZ MACHINERY

France

Designed for use with 3 and 4 wheel forklift trucks. Electro-hydraulic lifting, telescopic lip Side safety rails 24cm high, retractable Hot-dip galvanized grating non-slip running surface IP65 control panels Applications: The EASY-ST model is very popular with logisticians and industrialists, it allows you to integrate your loading ramps in the pit, thus allowing the optimization of circulation spaces.

Request for a quote

KRAUSE-WERK GMBH & CO KG

Germany

Telescopic multipurpose hinged ladder and 4 rail extensions Working height: 5,00 m - 6,05 m

Request for a quote

KRAUSE-WERK GMBH & CO KG

Germany

Televario Hinged Telescopic Ladder with four rail extensions Working height: 5,00 m - 6,05 m

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

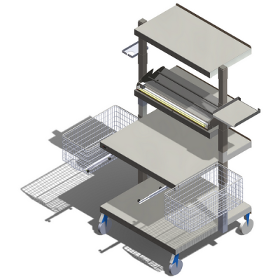

This mobile workstation is produced for packaging sterilized products, examining surgical instruments, etc. The Workstation includes a mobile base element, a large worktable with lower and upper shelves, autoclavable 1STU baskets, Barcode reader and thermal printer racks. • 2 Pcs. Upper Stocking Rack Grb (223300017SA4), • 1 Pc. Side Shelf Left Grb Mini (223300015SA5.2), • 1 Pc. Side Shelf Right Grb (223300015SA5.1), • 1 Pc. Manual Roll Cutting Apparatus (A065 222110021), • 1 Pc. Working Table Grb (223300015SA2), • 1 Pc. Telescopic rail system, (223300015SA1.2.1), • 2 Pc. autoclave basket (A072222110050), • 1 Pc. Lower table Grb (223300015SA1). • 1 PC. Allen wrench. • Dimension (Width x Deep x Height) and Weight 800 x 808 x 1700mm 80Kg. (excluding device, baskets and other accessories).

Request for a quote

GUNDEM SAGLIK VE GIDA URUNLERI SAN. VE TIC. A. S.

Turkey

This mobile table has been produced for the purposes of packaging sterilized products, examining surgical instruments, etc. The mobile desk includes a mobile essential element, a heightadjustable desk. • Mobile table with four wheels, two of which have brakes, the size and height of which the device and the front table can be easily adjusted by the user. • This table is stainless oven painted and its top is AISI 304 stainless steel. • It has a telescopic rail system for attaching one autoclave basket or large MDF drawer (A074) or small MDF drawer (A073) under the table • This basket/MDF drawer can be pushed under the table (with drawer logic) when not in use. • It can be ensured that the bags thrown from the front by the Cutting and Closing Devices are thrown into the basket/MDF pull. • A025 Grouping Tray, which provides grouping/regular accumulation of bags, is suitable for this table

Request for a quoteResults for

Telescopic rails - Import exportNumber of results

31 ProductsCountries