- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tempered steel strip

Results for

Tempered steel strip - Import export

EC PLAZA

South Korea

<Product Description> All things are standarded and customer can chose just folling its own needs without limitation in use of non commercial sizes. Our raw materials are used only domestic produced for the best guarantee in terms of quality and fair-play even for environmental. In more then 20years of activity .we have been producing a high quality steel strips for different industrial and technical purposed gaining experience to get best results in each market. All processes are done on most modern hardening and tempering facility lines. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Galvanized Steel Strip、Blue Steel Strapping

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Standard: AISI, ASTM, GB Place of Origin: China Technique: Cold Rolled/hot rolled Surface Treatment: Polished Application: Construction, Construction and hardware Thickness: 0.25mm-25mm Width: 16-1500mm Length: Customers' Requirement Certificate: ISO9001/SGS/BV Type: Steel coil Edge: Round Surface: Black Supply Ability: 5000 Ton/Tons per Month Hardened and tempered heat treatment steel strip for construction Packaging Details: standard sea worthy package Payment Term: T/T,L/C etc. Port of shipment: Xiamen,China

Request for a quote

EC PLAZA

South Korea

<Product Description> Bartex Steel Strip & Textured steel strip is a specially heat treated, cold rolled with high carbon steel SAE1078,1080,C80W. In its delivered condition, Bartex has a significantly higher tensile strength and dimensions yield to tensile ratio compared to hardened and tempered material of similar dimensions. The mechanical properties of Bartex are further enhanced by using a controlled strain aging heat treatment. Based on specific applications, strain aging process can be applied to the formed spring. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> SUS420 is a general purpose edium carbon straight chromium high hardenability martensitic stainless steel with good strangth and fairly good corrosion resistance. this grade offeres hardened & tempered martensitic stainless steel 420J1.420J2 440A grades,for custom stainless steel to meet your specific application requirments.high preformance stainless steel strip. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> Type 201 stainless steel is Austenitic stainless steel 201 stainless steel with Acid Alkali resistance and high density,no bubbles,nopinhole polishing etc. 201 and 202 is used for to make watch case,watch band bottom with best quality etc.it,s mostly used for make tubes, this is the main usage of 201. Also used for building decoration. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> 430: Stainless steel is a low-carbon plain chromium ferritic stainless steel. Mainly used for kitchen grade tables and utensils along with other applications not demanding in anti-corrosion properties. However, the stainless steel has good corrosion resistance in mildly corrosive environments and good resistance to oxidation at elevated temperatures. The steel has limited weldability and should not be used in the as welded condition for dynamic or impact loaded structures. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> 304 & 316 stainless alloy resists most oxidizing acids and can withstand all ordinary rusting. However, it will tarnish. It is immune to sterilizing solutions, most of the organic chemicals and a wide variety of inorganic chemicals. Stainless steel is used for critical environments that require a higher level of resistance to corrosion than Type 304 can offer. Type 316 is also austenitic, non-magnetic, and thermally non-hardenable stainless steel like Type 304. The carbon content is held to 0.08% maximum, while the nickel content is increased slightly. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> 301 stainless steel is produced with 20high mills and tension leveller process that is particularly well suited for the manufacture of high strength room temperature springs. Precision Steel 301 stainless steel in the, 1/4 hard, 1/2 hard, 3/4 hard, full hard, and extra hard tempers Stainless steel 301 is known for its high strength and excellent corrosion resistance. Alloy 301 is non-magnetic when annealed however it has the ability to be modified along with its other properties. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> Our bandsaw blades are widely applied in cutting beef, poultry, pork, frozen meat and fish, especially for meat with bones. The bandsaw blades are processed by Gronding to ensure the smooth and teeth. Manufactured using high quality ally steel (SK4)with unique heat treatment technology results in excellent tooth rigidity without losing flexibility. Our advanced grinding, teeth shaping, high frequency quenching process enables our blades to be suitable for the following applications. <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

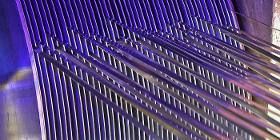

<Product Description> Our reed could help the weaving loom to get high performance,high speed and high quality fabric. We have a punch machines,polish machine,straight machine and other machineries. Our company is supplying a high quality dent with SUS420J2 & SUS301. <Product Specification> Thickness(mm) : 0.14/0.16/0.18 ~ 0.70 Width(mm) : 103 ~ 118 Tencile Strength(N/mm²) : 1450 ~ 1700 Hardness(HV) : 520 ~ 550 <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

EC PLAZA

South Korea

<Product Description> 1. Made from high quality,hardened carbon steel for added durability 2. Universal Fit Either 1"(25.4mm)hole sizing with your Blade Hrardware 3. Suitable for cutting different grass,weeds,brush and shrubs. * UFO BLADE is made to levitate so that it is not difficult to work on. <Product Specification> Thickness(mm) : 1.8 / 2 Width(mm) : 80 & 90 Steel Grade : AISI420 & SK5 & SKS51 Kind : Basic & UFO <Our Company> SAMSUNGSTS is leading manufacturer which is specialized in cold rolled, hardened tempered high carbon steel strip & alloy steel strip & stainlesss steel strip coil & Brush cutter blade & Meat bandsaw blade & Slice bread blade. we are supplying materials 17countries(Janpan, USA, Germany, Sweden, Italy, UK, Rumania, India, Indonesia, Singapore, Taiwan, China) with competitive price and best quality.

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316

Request for a quote

STAINLESS BAND LTD

United Kingdom

Stainless Band has in house rolling facilities to produce temper rolled strip in various hardness or tensile to suit client requirements. Stainless Band Ltd has in-house rolling facilities to flatten and produce temper rolled stainless steel strip to suit client requirements. These are available in various hardness or tensiles to reduce cross camber or “D” Section. For higher tensile over 1000n/mm2 (330vpn) we can supply precision mill material. Our production capacity for stainless band temper rolled strip is 0.10mm up to 2.0mm with a hardness range of 0.1mm up to 2.0mm with VPN ranges TR 230, TR 280, TR330, TR380 and TR430 and tensile ranges of 800+ 1000+ 1200+ 1500+ and 1900+ n/mm2. Stock grades are 430, 301, 304 and 316. Our production capacity for stainless band flattening provides a gauge range: 1.00mm up to 3.0mm, with a width range: from 10mm to 110mm, stock grades: 430, 301, 304 and 316.

Request for a quote

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

- Wide range of steel grades: structural, cold forming, HSLA, etc. - In coils or cut-to-length - Standard os curtomized sizes

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Precision re-rolled stainless steel strip products can be engineered to specific customer requirements with exceptionally short lead times. Based on our longstanding expertise, we can manufacture stainless steel strip to precise custom sizes, ultra-thin gauges and tightly controlled mechanical properties with any surface finish. We also work closely with Hamilton Precision Metals, part of AMETEK Specialty Metal Products, to produce stainless steel foils down to 1.5 microns (.000060”) thickness. Standard Alloys We manufacture stainless steel strip in a variety of chemical and mechanical properties, expertly engineered to your exacting specifications. High performance stainless steel strip material includes: Austenitic: 300 series Martensitic: 400 series Ferritic: 400 series PH Grades 17-7PH®, 17-4PH® Additional options available on request

Request for a quote

EURASIA METAL GMBH

Germany

Production standart : EN 10051 FOR HR MATERIALS - S235 JR, S275 AND S355 QUALITIES EN 10139 FOR CR MATERIALS - DC 01 , ST 12 QUALITIES EN 10025 – 1

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 430 is a corrosion and heat resistant ferritic Chromium Steel. It can be polished to appear similar to Chromium plate. The material is magnetic in both annealed and cold rolled tempers. The alloy can be readily blanked and formed. The material can be resistance welded, brazed, and soldered. SS 430 is resistant to atmospheric corrosion and fresh water, but it not resistant to most salts and sea water. It is resistant to scaling by oxidation up to about 1400°F. Available Sizes: SS 430 is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). The material conforms to ASTM A240, FED QQS 766, and UNS S43000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 420 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories, such as high quality surgical instruments. The alloy can be cold formed from the annealed temper.Welding should be accomplished by pre and post heating.Pre-heating at 450° F and post-heated at 1300° F will prevent cracking. The corrosion resistance is optimized in the heat treated temper and assured by passiviation. It is resistant to water and organic materials. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 410 is a heat treatable martensitic chromium stainless steel. Melt practice is controlled to develop a surface nearly free from defects. It provides the best combination of wear resistance and corrosion resistance, and is used in demanding medical accessories. The alloy can be cold formed from the annealed temper. Welding should be accomplished by pre and post heating. Pre-heating at 450° F and post-heated at 1300°F will prevent cracking. The corrosion resistance is optimized in the heat-treated temper and assured by passivation. It is resistant to water and organic materials, making it a good material to use in applications such as, rotary dies. Oxidation resistance remains favorable in most applications up through 1200°F.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 316L is an austenitic Chromium-Nickel stainless steel with superior corrosion resistance. The low carbon content reduces susceptibility to carbide precipitation during welding. This permits usage in severe corrosive environments such as isolator diaphragms, and metal diaphragms, for both aerospace sensors and burst discs. The alloy can be formed from the annealed temper by stamping and deep drawing. Joining is accomplished by brazing and welding. The Molybdenum is the alloy composition provides excellent strength up through 800° F in applications. Available Sizes: SS 316L is available from Hamilton Precision Metals as strip product from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000200” (0.00508 mm) in widths of 4.0” (101.6 mm) maximum. The material conforms to AMS 5507, ASTM A240, FED QQS766 and UNS S31603.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 305 is an austenitic Chromium-Nickel stainless steel with excellent corrosion resistance, and is suitable for very severe cold forming operations. A high nickel content reduces the work hardening rate so that it can be formed into electronic components and remain non-magnetic. The alloy is readily formable and work hardens slowly.It has good resistance to nitric and sulfuric acid solutions although it will not resist halogen acids. The alloy can be satisfactorily welded, brazed, and soldered. Available Sizes: SS 305 is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000200” (0.00508 mm) in widths of 4.0” (101.6 mm) maximum. The material conforms to ASTM A240, QQS-766, and UNS S30500.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 304L is an austenitic Chromium-Nickel stainless steel offering the optimum combination of corrosion resistance, strength, and ductility. These attributes make it a favorite for many mechanical switch components, and use in surgical instruments. Low carbon content reduces susceptibility to carbide precipitation during welding. The alloy is readily formed in the annealed temper.SS 304L may be joined by all commonly used brazing and welding methods including oxyacetylene. The corrosive resistance to acids is generally very good with the exception of halogen acids. Available Sizes: SS 304L is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.050” (0.0127 mm to 1.27 mm) in widths up to 12.0” (304.8 mm). It is also available in foil as thin as 0.000200” (0.00508 mm) in widths of 4.0” (101.6 mm) maximum. The material conforms to ASTM A240, ASTM A666, FED QQ-S-766, MIL-S-4043, UNS S30403.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 304L HN is an austenitic Chromium-Nickel stainless steel offering the optimum combination of corrosion resistance, strength and ductility. This makes it good for use metal diaphragms, for both aerospace sensors and burst discs. It has been remelted by ESR refining and conditioned to produce a minimum non-metallic impurity level. This will result in a surface that is most favorable for minimizing failures during severe forming operations. The high Nickel composition provides optimum ductility and formability from the annealed temper due to low work hardening rate. The low carbon content reduces susceptibility to carbide precipitation during welding.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 302 is an austenitic Chromium-Nickel stainless steel offering the optimum combination of corrosion resistance, strength and ductility. These attributes make it a favorite for many mechanical switch components, as well as surgical instruments. The alloy is readily formed in the annealed temper. SS 302 may be joined by all commonly used brazing and welding methods including oxyacetylene. Caution should be used to avoid cooling slowly through the range of 900° to 1600°F where carbide network could form and reduce corrosion resistance. This characteristic is diminished due to the typically low carbon composition of Hamilton’s SS 302. The corrosive resistance to acids is generally very good with the exception of halogen acids.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 301 is an austenitic Chromium-Nickel stainless steel capable of attaining high strength with moderate cold working. The combination of high strength and good ductility makes it suitable for numerous mechanical switches as well as surgical instruments, metal stampings and electronic and computer spring components.. The alloy is readily formed in the annealed temper. Ductility decreases with increased cold rolled strength but not to the degree that would occur with SS 302. It is not recommended for deep drawing. SS 301 can be welded by all conventional processed except oxy-acetylene. The weld should not make contact with electrolytes to prevent intergranular corrosion. SS 301 is resistant to atmospheric corrosion and is additionally resistant to mildly corrosive mediums. The combination of narrow strength bands and close thickness tolerance provided by Hamilton Precision Metals is the key to repeatable response characteristic in spring and switch applications.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 17/7 PH® is a precipitation hardenable stainless steel that is formable and also capable of meeting high strength requirements. It is utilized in applications that require both high strength and good corrosion resistance. The alloy is classified as semi-austenitic to distinguish the soft phase (austenite) available for ease of forming from the high strength phase (martensite) usually achieved by heat treatment. The alloy can be formed from the annealed temper but due to a rapid work hardening rate may not be deep drawn without intermediate annealing. It is joined by most arc and resistance methods used for stainless steel. It should not be fusion welded unless shielded by inert gas to prevent oxidation of aluminum.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

SS 17/4 PH® is a precipitation hardenable Martensitic stainless steel with high strength, and good corrosion resistance. This makes it perfect for use in metal diaphragms, for both aerospace sensors and burst discs. It is easily heat treated from the annealed temper. The corrosion resistance of the alloy is comparable to SS 302. It is heat treated at 900° F/1 Hour for highest strength. Other thermal treatments can be utilized to provide greater toughness and improved formability. Joining of the alloy is accomplished by the usual methods that are effective for stainless steel. Available Sizes: SS 17/4 PH® is available from Hamilton Precision Metals as strip product in thicknesses from 0.001” to 0.050” (0.0254 mm to 1.27 mm) and widths up to 12.0” (304.8 mm). The material conforms to AMS 5604, ASTM A693 and UNS S17400.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM® 455 is a precipitation heat treatable martensitic Stainless Steel. The composition provides a good combination of corrosion resistance and heat treated strength favorable for fatigue applications. The material is well suited for demanding spring devices The alloy has reasonably good forming characteristics in the annealed temper considering that it has a hardness of RC30. A significant radius is useful when bending is necessary in a fabrication. Cold working prior to the precipitation hardening treatment can drive finish strength up to 270,000 PSI (0.2% offset yield strength). The alloy retains a good strength through 800°F (Approx. 70% of room temperature). Resistance to stress – corrosion cracking is optimized by heat treating at 950°F. The overall corrosion resistant to normal atmospheric is equal to SS 430 with no staining. The alloy can be welded by resistance and inert gas shielded techniques. It also is suitable for brazing using a flux when possible.

Request for a quoteResults for

Tempered steel strip - Import exportNumber of results

32 Products