- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- track rollers

Results for

Track rollers - Import export

WIB SA

Switzerland

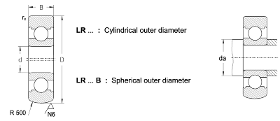

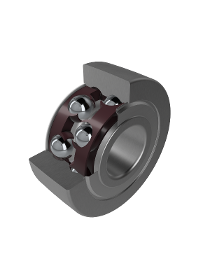

Track rollers—also referred to as idler rollers—are motion transmission components designed to work with all varieties of tracks. They are used in conveyor systems, cam drives, and a wide range of similar material handling systems. Regardless of the material or machine, these components play a critical role in track and rail operations. When selected, employed, and maintained properly, they facilitate system operations, allowing for greater speed and efficiency. Single row track rollers are available with spherical outer ring running surfaces or cylindrical (or flat) outer ring running surfaces. View our page of Special Profiles found under Technical Parameters for some of the more common profiles on the running surface.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS track rollers are available as self-retaining, single or double row ball bearings with particularly strong outer rings. In addition to high radial forces, they also absorb axial forces in both directions. Track rollers are characterised by their robust construction featuring particularly thick-walled outer rings with a crowned outer surface (alternatively with a cylindrical outer surface or outer profile). They are designed to carry high radial loads and also tolerate axial loads that can arise due to minor misalignments, skewing or short-term start-up shocks. The assembly is constructed with a fixed inner ring mounted on axles. In this case, the track rollers are not installed in a housing bore, but are supported on a flat raceway (mating track). To ensure a reliable seal, the track rollers are fitted with a lip seal or cover discs on both sides. This prevents the ingress of dirt, dust and other contaminants while maintaining lubrication inside the bearing.

Request for a quote

FATH GMBH

Germany

Prefabricated or single elements; resilient and smooth-running made of inherently stable aluminium or steel profile Individual elements —roller element, various Various versions —sliding rails, installation at two heights —Sliding ramp, smooth transition between different heights Different heights Ball element, low-wear and low-friction ball roller for flexible movement —Brush element, elastic brush fibres for gliding —reverse element, prevents backward movement —brake, gentle braking and starting speed —distance piece, as distance piece for staggered arrangement Accessories for roller rails —Holder, various for 4-sided and round profile —end plate, closure of the end face —guide rail, guiding/positioning Further accessories —stop buffer, damping of the stop —Roller holder, mounting on profile —Sensor holder, variable mounting of limit switches —backstop, prevention of tool carrier retraction Partially esd-capable and also available as individual parts

Request for a quote

TORWEGGE GMBH & CO. KG

Germany

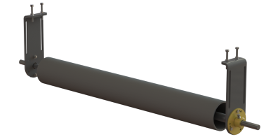

Our solid gravity-driven roller conveyors provide an optimized solution for the internal transportation of your lightweight or heavyweight products. In order to ensure that your conveyed goods flow smoothly and independently all the way from the inlet to the outlet point, the roller conveyor must have the proper declination. This factor must be determined individually according to the type of load carrier and weight of the goods being used for your application. We can also deliver complete solutions that are individually tailored to your requirements; our support already begins during the planning phase for your project. Take advantage of our in-depth experience and benefit from our assessment of your operating conditions and influencing factors (including the suitability of using roller conveyors for your goods) – Leave nothing to chance.

Request for a quote

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR5201/10-NPP mit schleifender Dichtung Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 5201/10 NPP 10 12 35 15,9 15,9 20,65 0,30 66 8500 5100 5100 10200 LFZ12, LFE12 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/8-6 NPP mit schleifender Dichtung Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/8-6 NPP 6 8 24 11 11 14 0,30 20 3670 2280 1300 4560 LFZ8, LFE8 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/8-6 KDD Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/8-6 KDD 6 8 24 11 11 14 0,30 20 3670 2280 1300 4560 LFZ8, LFE8 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/5-6 NPP mit schleifender Dichtung Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/5-4 NPP 6 5 17 7 8 10,5 0,20 10 1270 820 1300 1780 LFZ5, LFE5 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/5-6 KDD Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/5-4 KDD 6 5 17 7 8 10,5 0,20 10 1270 820 1300 1780 LFZ5, LFE5 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/5-4 KDD Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/5-4 KDD 4 5 16 7 8 9 0,20 9 1200 860 1300 1780 LFZ5, LFE5 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR50/5-4 NPP mit schleifender Dichtung Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 50/5-4 NPP 4 5 16 7 8 9 0,20 9 1200 860 1300 1780 LFZ5, LFE5 "

SMALLTEC GMBH & CO. KG, DOMAIN LINEAREASY.COM

Germany

Product description Track roller Typ: LFR5201/10-KDD Type dw d D C B -0,12 A r Gew in g Cw in N C0w in N Frz in N F0rz in N empfohlene Zapfen LFR 5201/10 KDD 10 12 35 15,9 15,9 20,65 0,30 66 8500 5100 5100 10200 LFZ12, LFE12 "

BME BAUMASCHINEN ERSATZTEILE INH. DIPL.-ING.(FH) MATHIAS SCHMIDT

Germany

From us you get wearresistant track rollers made of highquality materials. They have been specially manufactured for use in industry. This means that they are particularly robust and can withstand even extreme operating conditions on site. The most important quality features are the high wear resistance and consequently the long service life. This is made possible in particular by the use of highquality materials such as boron steel. Deep heat treatments and the most precise machining processes are used in production. In addition, quality controls are carried out during and after production. This also ensures that the high requirements are met. Our goal is a high level of customer satisfaction, and this is achieved first and foremost through quality with the track rollers in our range.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

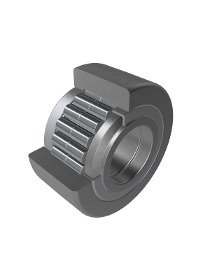

Our yoke type track rollers are available as single or double row needle roller or cylindrical roller bearings. Depending on the application requirements, the KIS range offers different ready-to-fit variants. Equipped with particularly thick-walled outer rings, our yoke type track rollers can support high radial loads and tolerate axial loads from minor misalignments, skewed running or short-term start-up shocks. Yoke type track rollers are mounted on axles and supported on a flat raceway (mating track). To meet specific requirements, we offer a wide range of different variants. Together with you, we develop the customised KIS solution carefully considering the use of cages, rib rings, seals and the profile of the outer ring running surface.

Request for a quote

DOREY

France

Removing the roller tracks by independent heating up to 220 ° C Adjustable speed of laying tracks up to 5 m / min Manual loading of sheets Side guides adjustable micrometer Winding device holder with the magnetic track detection cell in case of breakage. Mounting Tape with voltage control, and adjustable positioning guides the rollers. Positioning + or 0.1 mm servo motor 0,75 KW Cleaning system with a double face support roller on the output Storage formats tracked on a table with two anti static positioned before the guillotine and before the table Touch screen control friendly, multi lingual (French and / or English), setting and trimming various counts Use of electrical, hydraulic and pneumatic standardized Safety guards for strict compliance with CE OPTIONS MTL 700 NSA automatic loading of sheets Roller and additional heating system for a different bandwidth

Request for a quote

WIB SA

Switzerland

These track rollers offer the same features of a single row track roller with the added benefit of heavy radial, thrust or combined loads. Yoke-type track rollers are single or double-row units mounted on shafts or studs. Similar to the single row track roller, we can customize the running surface to meet the specific requirements of the applications. Cam rollers are similar in their construction to single and double-row support rollers, except that the raceway is formed by a heavy-section roller stud with a fixing thread. The most common running surface profiles can be found on the Special Profiles page under Technical Parameters.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SCHULZ STANZTECHNIK GMBH

Germany

Application Rollers are particularly well suited to the transport of light conveyed material with a smooth and stable underbody. They are used in roller strips, roller tracks, flexible roller conveyors and curved conveyors. They are used in push-through rack storage systems, as deflectors and guide tracks as well as for interlinking different conveyance systems. Load The load-bearing capabilities can be found in the table of dimensions under the “Roller” tab. The conveyance speed of Schulz rollers is up to 2 m per second.

Request for a quote

RACK CONCEPT

Belgium

In addition to organising storage according to the FIFO principle, dynamic parcel shelving incorporates roller tracks. Advantages Perfect rotation of parcels (FIFO system). Saves space and time in handling parcels Elimination of interference in order picking.

Request for a quote

PRESSTA EISELE GMBH

Germany

Helping hand: Lifter for placing profiles on roller tracks or loading magazines. Pneumatic lifting and feeding of profile bars by conveyor belt Adjustable stops to place the bar to correct position. Function: The bar is pushed against a contact surface – the bar lift up automatically and feed to load. Automatic lowering when position is reached. Belt speed: 9m/min Belt dimension: width 50mm, length 1400mm Lifting stroke: 250 – 1350mm adjustable Max. Profile weight: 90 kg

Request for a quote

RACK CONCEPT

Belgium

System for storing perishable goods, applicable to all sectors of industry or distribution The shelving incorporates slightly inclined roller tracks that allow pallets to be moved by gravity or at a controlled speed to the opposite end. Benefits Perfect pallet rotation (FIFO system). Saves space and time when handling pallets. No interference in order picking. Excellent control of stored product.

Request for a quote

BME BAUMASCHINEN ERSATZTEILE INH. DIPL.-ING.(FH) MATHIAS SCHMIDT

Germany

BME BauMaschinen Ersatzteile is a Europewide operating company. Our core competence is the distribution of highquality (OEM) system solutions, accessories and spare parts for machines in the construction industry. The satisfaction of our customers is a daily driving factor for us. Our central corporate objective is to provide added value through our service to major customers, small and mediumsized enterprises as well as private individuals. The products from our assortment come from leading international manufacturers. The quality of our products is essentially characterised by their reliability and long service life. Product range • Final drives • Rubber tracks • Steel (track) chains and Chain links • Rubberized floor plates (Roadliners), Rubber pads for steel (track) chains • Sprockets • Idlers • Top rollers • Buttom rollers • Industrial tires • Chain driven undercarriages

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Similar in design to yoke type track rollers with axial guidance, our KIS cam rollers are based on needle roller or cylindrical roller bearings. Instead of an inner ring, they are equipped with a solid bolt. This serves as an inner ring replacement and is provided with a fastening thread. They are ideal for applications that require high rigidity, load carrying capacity and guiding accuracy. Our stud type track rollers are used, for example, in conveyor technology, machine tools and medical technology. Depending on the application requirements, the KIS range offers a wide variety of designs. We are happy to advise you on the right solution for your application!

Request for a quote

SCHNELL SPA

Italy

Electromechanical automatic bar cutting bench with 5 transfer roller tracks and a second additional rebar conveyor. Thanks to the second transfer track, parallel to the cutting unit, cutbars can be placed along the whole length of the roller track optimizing the use. This means that the same roller track can be used to store different orders. Basically, it is as if you had a much greater number of roller tracks allowing a better cutting optimization thus reducing the quantity of scraps. The bar cutting bench "OPTIBAT 5" represents the ideal solution for those working large numbers of smallsized orders and it is especially designed for civil housing. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quote

SCHNELL SPA

Italy

Electromechanical automatic rebar cutting bench with 3 transfer roller tracks and a second additional rebar conveyor. Thanks to the second transfer track, parallel to the cutting unit, cutbars can be placed along the whole length of the roller track optimizing the use. This means that the same roller track can be used to store different orders. Basically, it is as if you had a much greater number of roller tracks allowing a better cutting optimization thus reducing the quantity of scraps. Besides being flexible and fast, its electromechanical technology ensures high accuracy; minimum noise production; reduced power and air consumption; reduced maintenance.

Request for a quote

CRAEMER GMBH

Germany

Original Palgrip® pallets from Craemer offer unparalleled smoothness and tracking on roller conveyors or chain conveyors. The abrasion-resistant anti-slip plates provide excellent slip resistance on the deck or under the runners. The high quality Palgrip® grain structure ensures an absolutely secure hold even in damp conditions. Palgrip® provides an all-round reliable solution to your logistical requirements. Only available from Craemer. The Palgrip® anti-slip coating is resistant to cold and heat, from -30°C to +40°C. Compared to common plastic surfaces, Craemer Palgrip® anti-slip sheets offer absolute slip resistance even in high humidity thanks to their grain structure. The unique Palgrip® anti-slip panels are made from high quality HDPE and are permanently part of the deck and the anti-slip runners will last the lifetime of the pallet. Even in an inclined position, your load remains static on the pallet deck

Request for a quote

BIZERBA SE & CO. KG

Germany

For installation in load carrier such as roller tracks and conveyors. For weight recording of different products. Depending on the type of load carrier and product one ore more weigh modules may be used. The weigh modules are impressive due to their robust and reliable design ensuring low maintenance operation and minimal wear.

Request for a quote

BIZERBA SE & CO. KG

Germany

For installation in load carriers such as roller tracks and conveyors. For weight recording of different products. Depending on the type of load carrier and product one ore more load corners may be used. Load corners impress due to their robust and reliable design and ensure a low-maintenance and low-wear operation.

Request for a quote

TECNORULLI S.R.L. CON SOCIO UNICO

Italy

With PVC pipe and head, with steel tube and PVC head. They are mounted vertically with sliding guide functions; horizontally for special applications such as the mounting for tangential belts in motor-driven conveyors through driven base rollers or rollers with pulley for flat belt. With plastic wheels on steel axles, assembled in sequence, they are used as an alternative to tapered rollers in gravity curves for the handling of packages with a flat supporting surface and light loads. The wheels can be individually assembled, fixed on flatbeds by means of suitable brackets, in correspondence with exchanges between curves and tracks with idlers, in conjunction between tracks with ortogonal motor-driven rollers or with the function of guide-abutment of packages.

Request for a quoteResults for

Track rollers - Import exportNumber of results

49 ProductsCountries

Category

- Bearings, roller (4)

- Cutting - steels and metals (4)

- Bearings - ball, needle and roller (2)

- Bearings, ball (2)

- Construction machinery (2)

- Industrial cutting machine tools (2)

- Travelators (2)

- Weight and mass - measurement and regulation instruments (2)

- Conveyor belts (1)

- Conveyor systems (1)

- Cutting - machine tools (1)

- Goods handling systems, continuous (1)

- Measurement - Equipment & Instruments (1)

- Pallets (1)

- Racks and bins (1)

- Shelving, storage (1)