- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filtering bags

Results for

Filtering bags - Import export

MAKENAS GRAIN MILLING TECHNOLOGY

Turkey

It is used to clean jet filter bags that lose their filtering function over time due to dust particles

Request for a quote

KIMTEK FKM FILTRE LTD. ŞTI.

Turkey

Bag filters are used by clean air requirments as pre and final filter. Pocket filter are made of non woven synthetic, fiber media to ensure retention of solid particles up to stipulated micron rating. These are covered with supporting layer of spun bonded media to avoid any type of particles or fiber migration, even after high pressure build up and mounted in special frames. The filter frames are from plastic or galvanisied metals. According EN779 Bag Filters goes from F5 to F89 Class available in various pocket length and quantities

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

Miele Type E, S217- S226, Deluxe, Electronic

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

Bosch Siemens Typ D-E-G-H-F

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

Rowenta- Tefal Hygiene+

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

Suitable for; Electrolux DP 9000, UZ 920 - UZ 925, UZ 930, UZ 930 S, Z 970, Z 990 Nilfisk DP 9000, GD 930, UZ 930, UZ 930S Volta UZ 173, UZ 920 - UZ 930 S, U 945

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

suitable for industrial vacuum cleaners

Request for a quote

HAKSAN KAGIT TORBA SANAYI

Turkey

Suitable for; BOSCH BSG 80000-89999 Ergomaxx,professional Original: BBZ 52 AFP, Typ P SIEMENS VS 08G 0000-9999 Dynapower,dynapower XXL, VZ 52 AFP Privileg 160.638.3, 239.550, 289.449.1, 330.095.1, 703.698

Request for a quote

PARSMEGA MAKINA

Turkey

This type of filters are used to separate dust particles from dust-laden air, they can be used with positive or negative pressure, the filter bag is cleaned by 0.5 bar pressurized clean air that does not contain oil and water.

Request for a quote

ROBINSON CO.

Turkey

Jet filter cleans the air dust mixture from dust, keeps the dust and ensures that the clean air is discharged from the chimney. The circular filter body first performs the cyclone system purification, and ensures that all dust particles are retained through the bags. It is used to separate the particles in the air used for aspiration and transport in flour mills from the air. Air containing dust and flour enters the machine and this dust sticks to the filter bags in the machine. First purification is carried out thanks to the centrifugal power generated in the round filter body. These filter bags are whipped with compressed air and the dust goes down to the bottom of the filter. Blower or compressor is used for this cleaning process. A bottom scraper or rotoflow is used for throwing these dusts accumulated under the machine. Applications Fields ◾ Food industry ◾ Flour and semolina mills ◾ Feed mills ◾ Grain cleaning plants ◾ Corn processing plants

Request for a quote

PARSMEGA MAKINA

Turkey

The air purifies the flour dust mixture from flour dust, traps the flour dust and ensures that clean air is expelled from the chimney. Flour dust captured by specially woven bags returns to the system. Thus, flour loss is prevented. The filter section body is made of 2-6 mm sheet metal and the lower part is a cast iron plate. The transmission and engine parts are located on the cast plate. The gearmotor is mounted on the transmission as a battery. The transmission located in the filter section drives the steel plate arm also located in this section. There is an air suction cup on this steel arm. This air suction cup closes the filter bags on its upper part and located in the pipe section, one by one, at regular intervals (with the help of the transmission movement arm) and sucks the product inside. Meanwhile, the clean air included with the product

Request for a quote

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The particulate filter cleaning machine is designed to clean the particulate filters of both passenger cars and commercial vehicles. The machine is completely made of stainless steel. With the water purification system, water in the tank is recirculated and cleans the inside of the particle filter.The machine starts the washing process by measuring the clogging rate of the filter after test button on the touch-operated display is selected. After the washing process is completed, you can test again and measure that the filter is cleaned. Then you can finish the washing process and proceed to the drying process. After drying the inside of the filter, the cleaning process is fully completed. There are bag and cartridge filters on the machine. Tank has heat insulation. The machine has lighting and a steam discharge fan. You can wash and dry 2 different filters simultaneously, as the machine has individual washing and drying processes.The machine exist in manuel and pneumatic.

Request for a quote

ZORLU DEGIRMEN MAKINALARI LTD. STI.

Turkey

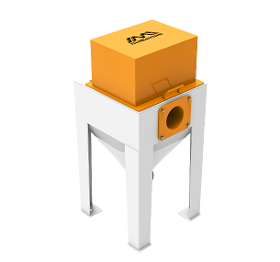

The supersonic filter is used for the separation of air-dust mixtures coming from the aspiration system as well as pneumatic conveying systems. The air-dust mixture enters the machine and the dust remains on the filter bags. These filter bags are shaken out using pressurized air by the diaphragm system and the dust is collected at the bottom of the filter. For the removal of the dust collected at the bottom of the machine, a sweeper can be used as well as a conical bottom with a rotoflow.

Request for a quote

AUROMAK MAKINA

Turkey

Stand; It should be able to operate without any problem in the ambient temperature range of 0°C to +60°C. In addition, there lated machine should operate without any problems in heavy humidity and dusty working conditions. The machine works with PLC screen system. The installed DPF for cleaning is first subjected to a clogging test. According to the result, the cleaning process is started with different washing and pressure parameters. Before and afte rwashing, a report is received and delivered to the customer. The machine, which is designed for all kinds of DPFs, has all kinds of apparatus. A platform system that moves up and down to compress special filters is provided as standard on the machine. Special bag, cartridge filters, liquid level controls are provided as standard in the machine and it works completely digitally.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KIMTEK FKM FILTRE LTD. ŞTI.

Turkey

Filter bags are manufactured for optimum filtration performance. They are made from carefully selected media developed specifications the process industry. Various types of media are used such as needle felt, monofilament and multifilament. They are effective in reducing dust emission level as requirement of industries. These bags are placed in dust collector with supporting filter cages. Contaminated air takes path of outside to inside filtration. All solid contaminants get deposited at outer surface & clean air / gas passes through top chamber. Particles retained at outer surface of media get collected at bottom of dust collector with help of shaking mechanism or reverse pulse jetting mechanism.

Request for a quoteResults for

Filtering bags - Import exportNumber of results

19 ProductsCountries

Company type

Category

- Vacuum cleaners, domestic (8)

- Filtering equipment and supplies (2)

- Flour milling - machinery and equipment (2)

- Oils, cooking - machinery and equipment (2)

- Vacuum cleaners - industrial (1)

- Cleaning machines, industrial (1)

- Industrial washing facilities (1)

- Concrete preparing - machinery and equipment (1)

- High-pressure cleaning machines (1)