- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- wedge wire

Results for

Wedge wire - Import export

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Thus, centrifugal wedge wire screen is suitable for the different kinds of applications where accurate filtration is required. Advantages Special surface treatment Centrifugal customizable basket design Corrosion resistance Durable and long service life Precise filtration Strong mechanical properties Applications Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. Mining Applications Water Treatment Chemical Fertilization Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

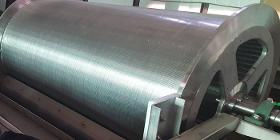

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the Vwires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easytouse and easy to clean compared to the other wedge wire types Advantages: Special surface treatment Portable customizable design Corrosion resistance Efficient filtration Suited for many applications Applications: Water Treatment Water intake Food processing Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

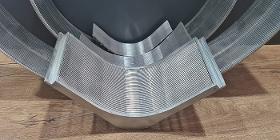

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: High filtration performance Customized bend screen design Corrosion resistance Durable – long service life Precise open gap High capacity compared to panel wedge wire screen Applications With the advantages of the bend screen geometry, they are used in different applications as a filtering element. Mining process Water treatment Food processing Particle filtration Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications Applications: Water Treatment Mine, coal, mineral Processing Food and Beverage Petrochemical and oil

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. Advantages 1-Special surface treatment 2-Modular and customizable design 3-High durability 4-Suitable for heavy applications 5-Superior filtering with unique screen 6-Long service life & less maintenance Applications 1-Coal and Gold Mining Filtration 2-Mineral Processing 3-Water Treatment 4-Petrochemical Applications 5-Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The sieve bend screen – also called bend screen – comprises a curved screen for filtration. The bend screen filters by guiding the particles along with the curved sieve filter screen. The shape of the sieve bend screen offers high filtration because of the forces exerted from the particles in the flow over the sieve bend. Thus, it is used for different applications by benefiting from the bend screen geometry. Advantages: 1-High filtration performance 2-Customized bend screen design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap 6-High capacity compared to panel wedge wire screen Applications: 1-Mining process 2-Water treatment 3-Food processing 4-Particle filtration 5-Coal removal Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The wedge wire cylinder screen is the most popular screen that can be adapted to many applications. The shape of the cylindrical screen helps the filtration process complete accurately. It is also called Johnson Screen in some applications. With the modular design of the cylindrical screen, it provides efficient filtration performance for many applications. In addition, cylinder wedge wire screens can rotate or remain static depending on your application. Advantages: Cylinder screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the cylindrical screen are listed below as: 1-Special surface treatment 2-Modular and customizable design 3-Corrosion resistance 4-Durable – long service life 5-Precise open gap Applications: 1-Water Treatment 2-Mine, coal, mineral Processing 3-Food and Beverage 4-Petrochemical and oil

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The basket screen consists of cylindrical and tubular wedge wire screen which is suitable for centrifugal applications. Therefore, the conical or tubular shape of the screen basket helps the filtration process complete accurately. Centrifugal screen provides efficient filtration for unique applications with conical geometry. Advantages 1-Special surface treatment 2-Centrifugal customizable basket design 3-Corrosion resistance 4-Durable and long service life 5-Precise filtration 6-Strong mechanical properties Applications 1-Different applications are possible for the wedge wire screen basket such as vibratory centrifuge applications. 2-Mining Applications 3-Water Treatment 4-Chemical Fertilization 5-Food Processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The gap between the looped wires defines the filtration performance of the welded wedge wire screen. Welded wedge wires are used as a filter to eliminate bigger sizes or types of materials above the wedge wire screen. Special manufacturing is required to create equal loops between the welded wires. Welded wedge wire screen is used in heavy applications for high filtration performance. The main advantages of welded filter screen are Advantages Special surface treatment Modular and customizable design High durability Suitable for heavy applications Superior filtering with unique screen Long service life & less maintenance Looped wedge wire screen is adaptable for many applications including Applications Coal and Gold Mining Filtration Mineral Processing Water Treatment Petrochemical Applications Food Processing Stainless steel with different grades and different materials can be used. Also, special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages 1-Special surface treatment 2-Suitable & customizable design 3-Long service life 4-High durability – less maintenance 5-Effective filtration Applications 1-Food and Mineral Processing 2-Water Cleaning 3-Mining Applications 4-Vibrational Separation 5-Fermentation 6-Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The flat screen also called panel screen is a rectangular type wedge wire screen for filtration. Thus, the shape of the flat screen helps the filtration process complete accurately by vibration or flow. Panel wedge screen panels provide efficient filtration for different applications with suitable geometry. With the portable design of the panel wedge wire screen, it adapts to a wide range of applications with straight geometry. Advantages Special surface treatment Suitable & customizable design Long service life High durability – less maintenance Effective filtration The most popular usage of the panel filter screen is eliminating the big particles over the screen with vibration. Applications Food and Mineral Processing Water Cleaning Mining Applications Vibrational Separation Fermentation Water Treatment Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with high efficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths. Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages 1-Special filtration 2-Counterbore and customized filtration holes 3-Corrosion resistance 4-High durability – long service life 5-Precisely drilled holes 6-Special surface treatment Applications 1-Sugar Pulp Pressing 2-Water Filtration 3-Paper Mills 4-Pressing 5-Processing of Chemicals 6-Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The bicylinder screen also called drilled press screen is used for special filtering applications with highefficiency filtration. The drilled screen consists of a counterbore hole and looks perforated. Counterbore holes can be manufactured in different diameter and depths.Moreover, screens can also be manufactured in different thicknesses depending on your request and application. Advantages The bicylindrical perforated screen provides different advantages for filtration as a type of special filter screen in different industries. The main advantages of the bicylindrical drilled screen are listed below as Special filtration Counterbore and customized filtration holes Corrosion resistance High durability – long service life Precisely drilled holes Special surface treatment Applications Typical industries and applications of bicylindrical screens are Sugar Pulp Pressing Water Filtration Paper Mills Pressing Processing of Chemicals Seperation Process

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The rotary screen is a portable cylindrical wedge wire screen that can be used for filtration. Rotary screens are also called drum screen, operates with rotational movement. Drum screen filters using the open gap between the V-wires of the cylindrical wedge wire screen. Rotary drum screen is most effective for water filtration applications. Therefore, it is called rotary screen wastewater as well. With the rotation around the cylindrical axis, efficient filtration is achieved with the drum screen. Rotary screen is easy to use and easy to clean compared to the other wedge wire types Advantages 1-Special surface treatment 2-Portable customizable design 3-Corrosion resistance 4-Efficient filtration Applications 1-Water Treatment 2-Water intake 3-Food processing 4-Mineral processing Stainless steel with different grades and different materials can be used. Also, Special surface treatments are available for your application.

Request for a quote

ADVANCED ENGINEERING WEDGE WIRE

Turkey

The water well screen V or wedge shaped wires around an internal array of longitudinal support rods. It is designed for the well intakes. It is also called ‘V’ wire screens in some applications. These efficient screens ensure a long well life by minimizing clogging. Water Well screen also called Johnson Screen provides different advantages for filtration as a type of filter screen. The main advantages of the water well screen are listed below as: Special surface treatment Modular and customizable design Corrosion resistance Durable – long service life Precise open gap Suited for many applications

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-Vibrating Circular motion screens divide into several bulk grain size ranges, seven small amounts of over-or undersize or separate from impurities and foreign matter from the screenings. Vibrating screens are working with directed vibrations/amplitudes, which are selected on special product to screen, depending on the installation conditions. The screens can separate different fractions simultaneously. The choice of the screen size and dimension depend on the task. Advantages & benefits low operating costs, high operational safety, long service life good value for money compact design dust-proof design possible low wear different possible screening performance, depending on size and design different possible meshes and screen shapes possible different possible screen materials (PU, spring steel, stainless steel, wedge-wire screens, perforated plates, etc.) Construction The main components are: strainer with drive traverse strainers / cassette or tensioned version mechanism

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ADVANCED ENGINEERING WEDGE WIRE

Turkey

Coanda Intake Screen also called Coanda screen provides filtration with the special curve shaped wedge wire screen. Coanda Effect screen is mostly used for filtration of water depending on the Coanda effect principle. Thus, the shape of the Coanda screen helps the filtration process complete accurately by the exerted forces of flow. Advantages of Coanda Screen Water screen provides clean water to the channels with high performance and self-cleaning. The main advantages of the Coanda Effect screen are: 1-Special surface treatment 2-Customizable design for the application 3-No power requirement 4-Long service life with negligible operational cost 5-High intake performance 6-Effective cleaning and capacity The main applications of the Coanda Hydro screen are 1-Hydropower Plants 2-Agricultural Applications 3-Dewatering 4-Drinking Water 5-Sediment Filtering 6-Water Treatment 7-Waste Water Treatment We provide customized Coanda Screen depending on your project needs.

Request for a quote

ROLF KÖRNER GMBH

Germany

We produce basket filters and wire basket inserts of any kind according to customer specifications. Normally perforated plates with round or square perforation as well as wedge wire elements serve as base bodies. The filter baskets are lined inside or covered outside with plain or with pleated wire cloth, according to customer requirement.

Request for a quote

INTEGRA CABLE

Belarus

It is used for hanging flat optical cable on the supports of communication lines, power lines, light poles, between buildings and structures. It consists of an open housing with a ribbed contact surface, a wedge with an attached wire loop, and a «grater» — a perforated insert that is inserted between the cable and the wedge. The design of the clamp provides a firm hold on the cable. Product materials body, wedge, stainless steel insert, chrome steel hinge. It is recommended to be used for all sections of the cable route at practically any angles of its turn.

Request for a quote

SCHAKE GMBH

Germany

Head for formwork prop: can be fitted on top of formwork props to hold the wood formwork support for which 4 corner angles are welded Tripod stand: the formwork prop can be fixed simply by a bracket that is supported movably on the tripod stand Formwork clamp: large size for stepless fixing by wedge. Eccentric clamp: for tensioning wire from 5 mm - 10 mm, load up to 2.500 kg Formwork clamp: made of 8 mm thick bent flat-bar steel. Wing nut WOF 27, casting, preferred use for grid-pattern formwork etc.

Request for a quote

FILTERSAFE

Israel

The Filtersafe Leviathan Brush filters are reliable filters that work hard for you, designed for near zero maintenance. The filters are available with either wedge-wire or perforated screens. Both options use a heavy-duty, highly durable brush for cleaning high loads of suspended solids with continuous operation. The Leviathan Series Benefits: - Multi-Purpose Brush Filtration Solution. Optimized for industrial, municipal, and agricultural applications. - Huge filtration area in small footprint - Low operating pressure. - Continual operation – No down time when flushing. - Robust design with a single moving part means minimal maintenance. - Highly effective cleaning with over 99.2% Recovery Rate and full screen recovery. - P.V. Design according to: AD2000 Merkblatt. - Rubber lining on request

Request for a quote

RAFI ELTEC GMBH

Germany

RAFI Eltec has over 20 years of experience in the special technology chip-on-board. That gives us a profound understanding of processes and quality in the standard technologies and beyond. As a result, we meet your requirements for flexible and reliable implementation of technically sophisticated solutions. We even set new standards. CHIP-ON-BOARD TECHNOLOGIES • Chip-on-board bonding • Chip-on-chip bonding • Chip-on-flex bonding • Flip chip TECHNOLOGIES IN THE CLEAN ROOM • Die bonding • Wire bonding (aluminum wire bonding and gold wire wedge-wedge bonding) • Glob top casting • Optical casting • Application of HF seals

Request for a quoteResults for

Wedge wire - Import exportNumber of results

24 ProductsCountries

Company type