- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding units

Results for

Welding units - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Applications and projects : conveyor systems assembly lines robotic units screwing welding Poka-Yoke vision Pick and Place Some practical examples : roll-forming machine conveyor system with elevator assembly lines for plastic and metal components ergonomic workstation on assembly line unit for recovery, transfer and removal of springs on assembly line

Request for a quote

MAGNITO EU LTD.

Bulgaria

Steel table leg in double U shape, welded construction, powder painted, 1 unit heavy-duty metal plate with 16 holes. 2 legs in a set. All our products are Made in Europe.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Mould parting agent for entire range of plastics processing if an adhesion-dependent further processing requiring silicone-free parting agent is carried out Welding parting agent for arc welding and inert-gas arc welding As nozzle spray for extended service life of welding nozzle and keeping nozzle opening clear on automatic welding units As workpiece protection against baking and burning on of weld spatters Advantages and benefits Silicone free release agent with high effective substances from renewable primary products Prevents from burning in of spatters at welding nozzles, on workpieces and robots and increases the lifetime of the welding torch Builts up an evenly thin, nearly dry film, no creation of pores Enables the fast change and cleaning of the welding nozzle Easily washable with OKS 2650 Additional painting, metallising and printing after prior degreasing without any difficulties possible

Request for a quote

ENNOX BIOGAS TECHNOLOGY GMBH

Austria

Floating covers or sludge accumulations forming on the substrate surface in the digester can be combated with a pivoting stainless steel spraying unit PSD. Normally the spraying unit is welded into the gas dome or manhole cover, can be rotated 360 and can pivot within the space available. The water connection can be achieved with a STORZ or GEKA type coupling, alternatively with a standard threaded connection.

GSW SCHWABE AG

Germany

Safe upending (90°) and rotating (180°) of coils Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type highstrength chain Rotating drive via welded surfacehardened sprocket, integrated in base Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

GSW SCHWABE AG

Germany

Safe upending of coils (90°) Body design in solid welding construction with reinforced base with no pit or floor anchoring needed Body made of strong steel plates Base with large integrated floor plate and attached box construction to protect drive components Tilting unit with neatly welded half shell attachments and two reinforced coil tables welded at 90 degrees to provide safe material seating Bedding via four pressureresistant and fully enclosed bearings with lifetime lubrication Tilting shaft of highquality ductile steel with fully enclosed bearings Tilting drive via threephase motor and triplex type Highstrength chain Tilting function via initiator with arbitrary adjustable tilting point Electrical conrol in switch box with leftright selector switches and estop

Request for a quote

SCHNELL SPA

Italy

Cage making machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 2500 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. WIth the machine to produce cylindrical poles CM PRO 2500 it is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Cage welding machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 2000 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. With the machine to produce cylindrical poles CM PRO 1600/2000 it is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

SCHNELL SPA

Italy

Cage making machine for the production of cylindrical cages with variable pitch welded spiral wrap; max cage Ø 1100 mm. High productivity and flexibility is guaranteed by the configuration of the machine and by the fully automatic welding unit SAF 3000. With the machine to produce cylindrical poles CM PRO 1100 is also possible to produce on the machine square or rectangular cages and cages with the bars bent on the end (90 °bends, bottle necks and pointed).

Request for a quote

ORBITEC GMBH

Germany

Water cooling unit for application with Tetrix 200 inverter and Tigtronic Compact in conjunction with water-cooled welding tools. Technical Data: Input voltage: 230VAC Cooling system: F / IP 23 Weight: 16.5kg Dimensions (L x W x H): 610 x 298 x 330mm Tank capacity: approx. 4l Water column: 35m | 5l/min. Cooling capacity: 1000W (1l/min.) Package includes: - Water cooling unit - Connection cable inverter / water cooling unit - 5l coolant Also Cool 50 Water Cooling Unit, 115V | Item number: 1.1.0118 (Same characteristics as Cool 50 water cooling unit for input voltage of 115VAC)

Request for a quote

ORBITEC GMBH

Germany

Compact and lightweight wire feed unit mounted in a Peli case for 5kg (Orbifeed 5) and 15kg (Orbifeed 15) standard spools. External wire feed unit Orbifeed 5, for 5kg – spools (Item number 1.3.1701) External wire feed unit Orbifeed 15, for 15kg – spools (Item number 1.3.1702) Technical Data (Orbifeed 5 | Orbifeed 15): Motor voltage and power: 24DC, 6W | 24DC, 6W Weight: approx. 7kg | approx. 8kg Dimensions (L x W x H): 406 x 330 x 174mm | 525 x 436 x 217mm Wire spools: Standard spools 5kg | Standard spools 5kg and 15kg Wire outside diameter: 0.8 / 1.0mm | 0.8 / 1.0mm Package includes: - Water-resistant and dust-proof Peli case - Four roller drive mechanism - Delivery hose with inlet and outlet nozzles - Torch bracket for wire feed on OSW / OSZ / Turn - Interconnecting cables wire feed unit / controller

Request for a quote

ORBITEC GMBH

Germany

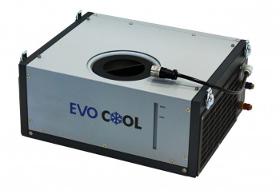

Water cooling unit for use with the EVO 200 WP or LITE controller and Tetrix 200 in conjunction with water-cooled welding tools.ols. — Standalone or continuous operation possible — Temperature-regulated fan control — Water flow feedback through in-built flowmeter Package includes: — Water cooling unit — Inverter / cooling unit (permanently mounted) connection cable — Fasteners for EVO series — 4 l blueCool 10i-5 coolant

Request for a quote

MOSCA GMBH

Germany

• Heat-weld sealing unit in standard-3 version • Wear-free DC drive, brushless motor technology • Easy strap coil change and threading system • Soft strapping with open sliding position for sensitive packages • Adjustable strap tension via potentiometer • Energy-saving drives • Electronic controls • Hinged table top made of stainless steel • 4 castors of which 2 are lockable • Strap feed from sealing head level via potentiometer • Quiet sealing unit • Package width min. 80 mm • CE marking inclusive conformity declaration

Request for a quote

MOSCA GMBH

Germany

• Heat-weld sealing unit in standard-3 version • Wear-free DC drive, brushless motor technology • Strap end detection with ejection of remaining strap • Easy strap coil change and threading system • Soft strapping selectable for sensitive packages • Low-wear, controlled strap path system • Adjustable strap tension via potentiometer • Energy-saving drives • Electronic control • Hinged front table top • Sturdy foot pedal for cycle start • 4 castors of which 2 are lockable • Table top length 600 mm or alternatively 700 mm or 800 mm • CE marking inclusive conformity declaration

Request for a quote

BEHA INNOVATION GMBH

Germany

Elastic monolithic PU conveyor belts from BEHAbelt offer new fabrication possibilities. Due to the lack of traction layers joining by finger welding is no longer necessary, as the monolithic belt has a homogeneous design – even in the weld seam. The welding device HS from BEHAbelt is a simple, handy, reliable and costeffective tool for butt joining of monolithic belts. Depending on customer requirements, two versions are available with the joining table and heating paddle for max. belt widths up to 400 and up to 800 mm. The simple operation in combination with the intuitive production aids enables a repeatable and highquality connection of the belts. Optional adapter plates ensure precise positioning and clamping of the butt ends to be welded.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KLN ULTRASCHALL AG

Germany

For the assembly of plastic parts, which differ in size and condition and would therefore not be suitable for standard machines, we recommend the use of special equipment with several ultrasonic units for ultrasonic welding and processing methods. • Riveting • Welding • spot welding • punching • flanging • cutting • embossing • printing Multi-head systems These machines can also be used to accomplish complex tasks, e.g. the combination of different welding techniques, like spin welding and hotplate welding and for numerous automated processes

Request for a quote

KLN ULTRASCHALL AG

Germany

The KLN QSW 400 L is a modular laser welding machine. The advantage of the modular structure is that the central laser welding machine can remain unchanged in the various welding tasks and only the housing and its frame structure must be adapted to the actual welding task. Thus, a well-tried laser welding unit can always be used. Moreover, adaptions to other welding tasks can be easily integrated, e. g. with rotary table, tool carrier, conveyeor or sliding table. Laser: Water-cooled diode laser with 300 W optical output power Wave length 980 nm ±10 nm Pilot beam at 650 nm ±15 nm (<1 mW) Optical fibre suitable for wave length 780-1030 nm Focal distance of collimation 58 mm Focal distance f-theta objective 635 mm Operating distance 728 mm Operating field (scan field) 415 mm x 415 mm

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION The machine is ideal for welding process of PVC plastic profiles at two corners. Fully automatic two corner welding of PVC window profiles at an angle of 90° The possibility of precise welding of profiles between 30°-180° on the left head All parameters such as melting and welding time, welding pressure are set on the control panel independently Continuous precision of welding quality by means of linear rails Welding two corners of window frames or sash profiles are carried out in one cycle User-friendly with practical Teflon change feature by means of the roller system Saving of time by means of most practical mold change system in the market Capable of adjusting the clamp and welding pressure according to the profile type Adjusting the heat between 0-300°C via electronic thermostat Practical setting of standard (2 mm) or seamless (0.2 mm for free of flashes) welding options The movable right unit moves manually and left welding unit is fixed at 90°

Request for a quote

YILMAZ MACHINE

Turkey

Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor Remote connection via internet and providing technical support

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

YILMAZ MACHINE

Turkey

PRODUCT INFORMATION Corner Cleaning Machines are designed for the cleaning of welding chips of PVC profiles that is welded at angle of 90°. CNC 608: 2 x servo drive motors, CNC 610: 4 x servo motor drives. After welding, operator or Robot mechanism (SA 260) automatically takes the frame from the place where the cleaning process start and carry out the cleaning of the flashes by means of the spinning mechanism Zero and standard welding can be selected from the screen All units parameters can be set inde pendently according to the frames Automatic frame and sash profile recognition system Automatic line can be made by combining with Four Corner Welding Mach.(DK 540), Cooling Unit (SA 250) and Rotating Robot (SA 260) at a later date Eliminate the flashes on the lower and up per surfaces by two independently operated cleaning units (CNC 610) Memory capacity of 6500 profiles Windows based industrial PC and 15’’ LCD touch screen color monitor

Request for a quote

MESSER CUTTING SYSTEMS

Belgium

Implementation: Hand torch for welding, brazing, soldering, heating and flame cutting Shaft diameter 15 mm Welding range to 14 mm Cutting range to 200 mm Available with DIN and BS connections for all fuel gasses Advantages: Universal field of application thanks to a wide selection of different torch inserts Especially robust version for extreme demands High media flow rates Easy operation of the mono-block valves High durability due to brass valve housing Ergonomic operation thanks to special handle shape Low spare parts stocks required thanks to modular system Scope of supply: Complete welding and cutting kits Individual units for welding, brazing, hard soldering and heating, flame cutting, flame straightening, flame scarfing Accessories, consumable parts

Request for a quote

MESSER CUTTING SYSTEMS

Belgium

Implementation: Hand torch for welding, brazing, soldering, heating and flame cutting Shaft diameter 15 mm Welding range to 14 mm Cutting range to 100 mm Available with DIN and BS connections for all fuel gasses Advantages: Universal field of application thanks to a wide selection of different torch inserts High media flow rates and easy operation of the mono-block valves Robust version and extreme durability due to brass valve housing Ergonomic operation thanks to special handle shape Low spare parts stocks required thanks to modular system Scope of supply: Complete welding and cutting kits Individual units for welding, brazing hard soldering and heating, flame cutting Special versions of handle Accessories, consumable parts

Request for a quote

MESSER CUTTING SYSTEMS

Belgium

Implementation: Small torch for welding, brazing, soldering and heating especially for applications in the jewellery and dentistry industries Shaft diameter 10 mm Welding range from 0,1 to 4,0 mm For all gasses Advantages: Various torch inserts from micro fine applications to powerful heating, melting and soldering work High safety levels due to injector suction principle Work without fatigue due to low weight Optimum freedom of movement due to compact size Can be used with all gasses Complete range of accessories such as bench lighter, holder etc. Scope of supply: Complete welding, brazing and soldering kit Individual units for welding, brazing and soldering Accessories, consumable parts

Request for a quote

MESSER CUTTING SYSTEMS

Belgium

Implementation: Hand torch for welding, brazing, soldering, heating and flame cutting, flame straightening and flame scarfing Shaft diameter 20 mm Welding range to 30 mm Cutting range to 200 mm Available with DIN and BS connections for all fuel gasses Advantages: Universal field of application thanks to a wide selection of different torch inserts Especially robust version for extreme demands High media flow rates Easy operation of the mono-block valves High durability due to brass valve housing Ergonomic operation thanks to special handle shape Low spare parts stocks required thanks to modular system Scope of supply: Complete welding and cutting kits Individual units for welding, brazing, hard soldering and heating, flame cutting, flame straightening, flame scarfing Accessories, consumable parts

Request for a quote

AYAZ AUTOMATIC WELDING MACHINES

Turkey

Being able to walk on a suspended type tank Single-sided tank welding Single operator control 1000 – 3000 mm plate welding Tank welding machine is an automatic tank welding machine designed for welding cylindrical structures that can weld with submerged arc welding in the side position (3 o’clock). The welding unit is fixed on a cabinet. On the upper floor of this cabin, where all safety conditions have been provided for the operator, there are motor and gear systems that move the system on the hardware sheet. Tank Welding Machine enables horizontal circumferential welding of large storage tanks with Submerged Arc welding machine. • The minimum diameter it can weld is 4.5 meters. • The lowest sheet thickness that can be welded is 6 mm. The outer cover is produced to protect the user from the external factors of nature. Our Tank Welding Machine is designed to weld either internally or externally.

Request for a quote

FIBERSCOPE.NET BY MEDIT INC

Canada

Hathorn Sewer Camera is a premium Canadian-built unit for rugged and demanding inspections. Operated by a 18V battery and welded from steel frame, this unit features high-end camera head that delivers quality images. Lengths: 100ft - 500ft. Camera dimeters: 1" , 1.23", 1.35, 1.43" and 1.68"

Request for a quoteResults for

Welding units - Import exportNumber of results

30 ProductsCountries

Company type

Category

- Industrial cutting machine tools (3)

- Welding, soldering and brazing - equipment and supplies (3)

- Metal straightening machines (2)

- Packing and packaging - machinery and equipment (2)

- Silicones (2)

- Welding, electric - equipment and supplies (2)

- Autogenous welding machines (1)

- Furniture - restaurants, bars and cafés (1)

- Industrial piping (1)

- Laser - cutting and welding machines (1)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (1)

- Motor mechanics - hand tools, non power (1)

- Spare parts for cars (1)

- Ultrasound systems - Processing plastics (1)