ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Manufacturer/ Producer

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Conching is an essntial process for natural chocolate production. During conching , viscostly of chocolate is reduced as a result of heat transfer mechanical agitation. Moreover moisture, volatile substances and undesired odors are removed by this process. According to process requirements conching takes approximately 3-12 hours and consist of six zones. The systems are thermostatically controlled.System takes cold water when needed.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Chocolate Moulding Line – Solid – Cream filled chocolate articles (one shot) – Cream with granule filled articles – Chocolate with granule – Chocolate with whole nuts – Demoulding by means of vacuum robot – Belt conveyor out-feed – Automatic empty mould feed system – PLC controlled – Granule mixer – Automatic mould heater

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Cooling Tunnel – Our cooling tunnel is used for cooling chocolate coated biscuits,jelly, nougat, fondant and similar products. – Belt widths 400,600, 800,1000, 1200 mm – Cooling unit is in the middle part of the tunnel. Two blowers supply the necessary air current. – Tunnel temperature is controlled by a digital thermostat. – Tunnel temperature can be down to 0°C. – Belt sped is controlled by electronic frequency drive. – Covers are insulted. – The tunnel can be cleaned by opening the top covers. – Tunnel has a automatic belt adjustment system. – Sharp edged infeed. – Tunnel has scrapers

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Wafer Cream Line

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Tempering Machines Tempering is necessary in order to obtain a perfectly finished product. Five construction features enable perfect microcrystallization of the chocolate mass. – Long tempering sections – Large cooling surfaces – Turbulent mixing – Cooling time – Accurate temperature control ATM temepring machines meets these requirements. Final product has these characteristics: – Unique gloss – Fine grained and dense structure – Extended shelf -life – Crispy break – Short cooling time – Maximum contraction

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Ball-Mill Ball-mill is batch type refiner for processing cream, natural and palm based chocolates and similar products. Ball mill tank is double jacketed and heated by electrical resistances. Inner and outer jacket , agitators and balls are stainless steel. System also includes thermostatically controlled heating system . The chocolate pump which is used for circulation is also used for discharging. Process time is depends on raw material fineness . Process takes approximately 2½ hours.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

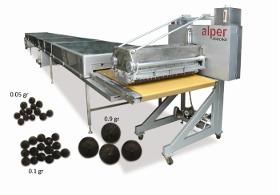

rop Line Chocolate drop size can be adjusted between 0.05 to 0.9 gr Each drop has its own piston Depositor has high precision since dosing is done by servo-motors. Depositor hopper is double jacketed and temperature controlled Depositor has agitator Easy cleaning PLC controlled Capacity: 33-600 Kg/hour

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Enrobing Machines Alper enrober is made with belt width from 400 , 600 , 800 and 1000 mm and designed for all common enrobing tasks with tempered as well as non tempered chocolate. On the machine there are following possibilities of enrobing. – Enrober can make bottom enrobing , top enrobing and combined bottom and top enrobing Combined bottom and top enrobing. – Partial enrobing by separation of chocolate curtain, it can be decided which part or parts of articles to enrobe – Designed for three shift operation – Stainless steel construction – Including one hot water system – Height adjustable blower with calibrated adjustable nozzle – Including return pump (optional) Frequency controlled : – Chocolate supply pump – Wire mesh band – Blower speed – Shaking device – Licking rollers

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 8-10 moulds/min. for 2500kg blocks 4-5 moulds/min. for 5000kg blocks Capacity : 1200-1500 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 90.000 kcal/hour Cooling Tunnel : Tower type cooling Couverture Moulding Line (KDH – 750) Precision depositing automatic weight adjustment (+/- 0,005) Piston drivers : Servo motor Control : PLC Touchscreen control panel Depositing speed : 4-5 moulds/min. for 2500kg blocks 2-3 moulds/min. for 5000kg blocks Capacity : 600-750 Kg/Hour Mould Dimensions : 400x300x50 mm Loose Mould System(without mould break) De-moulding : With Robot (product output direction and angle adjustable) Cooling Capacity : 45.

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

RAW CACAO SILO - CACAO ROASTER & ELEVATOR - CACAO LIQUOR PRODUCTION LINE (KFM-450) - MASS STORAGE TANK (ST-4000) - ALKALIZATION CONCHE - CACAO BUTTER PRESS - PRESS FAT TANK - CACAO POWDER PLANT - COCOA CAKE CRUSHER - CHILLER (C-50)

Request for a quoteManufacturer/ Producer

Beylikduzu

34520 Istanbul - Turkey

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

MIR HAN BAU GMBH.

Germany

Cocoa nibs are small pieces of the natural roasted cocoa bean. Very nutritious and healthy. A superfood with all the aroma of cocoa. Crunchy and with a delicious and intense flavour of pure, slightly bitter chocolate. They are rich in protein and healthy fats. Nibs are the cocoa beans that have been roasted, peeled and broken into smaller pieces. Likewise, being in their original form, they are not added with extra fats or unnecessary sugars. High in fibre, protein, iron, magnesium and potassium. You can enjoy them with fruit, cereal, ice cream or your favorite yogurt. They can even be used to decorate pastries or added to smoothies.

Request for a quote

FORMEX MAQUINARIA

Spain

•You can dispense: bonbon, liqueur bonbon and praline bonbon. •The chocolate can have solid particles up to 3 mm thick. •Model manufactured according to production needs and adapted to the customer's moulds. •The dosing area, both the tank and the dosing nozzles, are heated to facilitate the hot dosing of the chocolate at an adjustable temperature, ensuring an ideal condition of the product. •Volumetric dosing. •The conveyor belt incorporates a vibration system at the product outlet to eliminate any bubbles that may have originated in the product during dosing. •Removable head for easy cleaning and with the possibility of being interchangeable. •A tray loader can be added at the beginning of the belt or a topping unit after dosing.

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free