- europages

- >

- Magnets

- >

- ASSFALG GMBH

- >

- products

ASSFALG GMBH

Germany

Manufacturer/ Producer

ASSFALG GMBH

Germany

The FS 5 is a sturdy and extremely cost-effective chamfering machine with cutter head and cutting inserts. Straight edges of cube-shaped workpieces can be easily chamfered. It is designed for deburring and chamfering small workpieces starting with a thickness of 3 mm. The sturdy casing, the sanded guide rails and the integrated swarf boxes convince in every regard. The V-prism is foldable for changing the reversible cemented carbide inserts. Thanks to the optimised interplay of cutter head and cutting inserts, the machine ensures clatter-free, clean and constant chamfering. The chamfer setting is made through a knurled handwheel. A chamfer width of up to 5 mm is possible in NE metals and a chamfer width of up to 3mm in steel. The machine has a switch-on duration of 10 - 30%/h.

Request for a quote

ASSFALG GMBH

Germany

The SMA 30-A series is available in an electrical or compressed-air operated design. The machine is designed for handling steel, aluminum, copper and plastics. A chamfer width of up to 8 mm is possible in NE metals and a chamfer width of up to 6mm in steel. In addition to this, a radius processing of 1.2mm to 6mm is feasible. The stunning and patented 8 or 16 cutting turning plate system guarantees long service life, best surface qualities and efficient working. The electrical design of the SMA 30 is equipped with a speed control and should be preferably used for stainless steel processing. The cutter heads are available for chamfer angles 30°, 45° and 60°. The processing of drill holes is already possible starting at a diameter of >28mm. For tight contours, long holes and bores, a single-cutting cutter head with a fitting guide roller is available, Ø10mm to Ø20mm depending on application.

Request for a quote

ASSFALG GMBH

Germany

The small and compact chamfering machine is designed for chamfering small to medium-sized workpieces. The light aluminum casing, the wear-resistant and sanded work plate, the optional speed regulation and extraction sockets convince in every regard. The Speedy Contour is available in the type 270 and 320 designs, this refers to the able plate size. Both versions are available with and without speed regulation. For high-alloy materials, the speed range can be adjusted for speed-regulated machines from 10,000 to 30,000 rpm, through a technical change, to 2,800 to 7,400 rpm, and for machines without speed regulation from 20,000 rpm to 5,100 rpm. Thanks to the brushless motor the machine is perfect for continuous operation. Our versatile tool range includes different VHM milling cutters and CBN or diamond grinding pencils. The VHM milling cutters are available for the processing of chamfer angles and radii.

Request for a quote

ASSFALG GMBH

Germany

The ASO 600-ASL edge and contour deburring machine is designed for chamfering small to medium-sized workpieces. The refined machine features, such as the folding table, the tool-free spindle locking and the height adjustment guide for tool change convince completely in their performance. The durable steel casing, the wear-resistant and sanded workplate with extraction socket and speed regulation round off the total package. The speed range from 9,000-21,000 rpm is ideal for use of NE-metals up to high-alloy materials. Thanks to the brushless motor the machine is perfect for continuous operation. Our versatile tool range includes different VHM milling cutters and CBN or diamond grinding pencils. The VHM milling cutters are available for the processing of chamfer angles and radii. Ball bearings with Ø3, Ø4, Ø5 or Ø6mm are used for contour processing with the VHM milling cutters. Tapered contour chamfers are used in combination with guide fingers or stop rulers.

Request for a quote

ASSFALG GMBH

Germany

The automatic weld-chamfering machines from the ASO 900 series are for stationary and portable use in weld seam preparation. The attachment of large welded chamfers on the workpiece upper edge up to a chamfer length of 53mm can be performed by the machine effortlessly without any thermal change to the material, because the heat dissipation occurs through the chip. V, X, K or Y seams can be prepared thanks to the gradual angle adjustment from 15° - 80°. The machines are very durable and show their strength in every material through their sturdy construction. Extremely high tool service life can be achieved with the low-speed chamfering. Sheet thickness started at 8mm can be processed. Smaller workpieces can be processed manually. Advantages: Easy to adjust to material thickness, chamfer angle and working height No change to material properties, through heat dissipation via chip V-, X-, K- or Y- seams possible

Request for a quote

ASSFALG GMBH

Germany

The tub vibratory finishing machine, which has a size similar to a washing machine, with a fill volume of 70 l is our standard machine and is ideal for prototypes and small series. A noise protection cover reduces the noise and makes it possible to work in a workshop. The right and left-hand circulation as well as speed regulation from 1,500 to 3,000 rpm provide for various processing possibilities. The abrasive material and workpieces are rotated through the generated vibration. The desired processing process is created through the contact of grinding bodies on workpieces. The programmable timer rounds off the autonomous work process. The machine has a modular construction and can be expanded with an optional paper filter and separator. Both are controlled centrally through the control panel on the TV 95-SL. We recommend the PF440 paper filter for simple and comfortable water treatment. The S95 separator simplifies the separation of grinding bodies and workpieces.

Request for a quote

ASSFALG GMBH

Germany

Our deburring and edge rounding machines type TF enable an optimal Surface Processing up to the perfect surface finish in the dry grinding process. The Deburring & Edge Rounding Machines are available with 3 different passage widths. They have various performance spectrums, which are individually adapted to the modular principle customizable and configurable to customer requirements. Both small and large-area sheet metal parts or workpieces can be processed, regardless of the material. These conveyer machines thus show the best possible flexibility in sheet metal processing.

Request for a quote

ASSFALG GMBH

Germany

The weld edge forming/milling machines shear the edge with the help of a cutting wheel, completely self-propelled, noiselessly, and dust-free, leaving a rough bevel. They produce perfect welding edges with the best price-performance ratio. They can chamfer plates and pipes, including large diameters, as well as small parts and pipes with low thickness.

Request for a quote

ASSFALG GMBH

Germany

The automatic bevelling machine CHP 21G is designed for the stationary and portable use in weld seam preparation. A cutting wheel shears off the edge in a low-noise and dust-free way, leaving a rough chamfer. It is extremely robust and suitable for continuous operation. It delivers consistent and high-quality bevels in the sheet metal welding preparation process.

Request for a quote

ASSFALG GMBH

Germany

The new Enviro 1000 is an automatic water treatment system that purifies the process water and compound produced after vibratory finishing and reconditions it for renewed vibratory finishing operations. The centrifuge cleans and recycles the process water by separating the solid particles and often also oils from the process water and depositing them as solid sludge on the edge of the centrifuge basket used for this purpose. This cycle of processes: Vibratory finishing, cleaning and recycling the process water and finally reusing the process water in a renewed vibratory finishing process saves costs and is extremely environmentally friendly.

Request for a quoteManufacturer/ Producer

Buchstraße 149

73525 Schwäbisch Gmünd - Germany

europages also recommends

A selection of companies related to the activity:

A selection of products that might interest you

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

HOMESHOP

Poland

The Hinovo powerbank is a useful gadget with MagSafe or Qi wireless charging. The product achieves wireless charging with a maximum power of 15W. This allows any compatible device to be charged effectively. The powerbank can be charged via the USB-C port, which supports power up to 20W, which gives us about 3 hours of charging from 0% to 100%. The housing is made of non-slip ABS, which increases safety and prevents it from slipping out of your hand. In addition, protection against overheating of the device and a cooling system have been built in. The gadget is small in size and ideal for taking it with you on a trip to a backpack or handbag.

Request for a quote

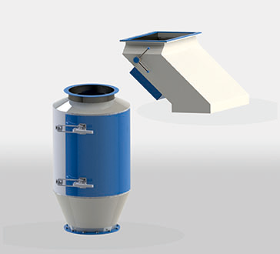

PARSMEGA MAKINA

Turkey

It is one of the auxiliary equipment that prevents metal and metallic parts from damaging the system by attracting them. Most of the machines working in Flour and Feed Factories rotate at high speeds. Screws and similar metal and metallic parts that break off during operation in the natural environment where the product comes from and in other machines enter our working machines and systems and cause damage. The magnet helps catch these pieces before they enter our machines and systems.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

The characteristics of Samarium Cobalt Magnet •Very high magnetic properties with good stability •Superior resistance to high temperature, Curie temperature of majority is over 800°C •Excellent corrosion resistance capability, no coating is needed for surface protection

Request for a quoteRequest for quotes

Create one request and get multiple quotes form verified suppliers.

- Only relevant suppliers

- Data privacy compliant

- 100% free