BASAK LAZER - Precision Sheet Metal Processing and Precision Cutting Applications

Turkey

Manufacturer/ Producer

BASAK LAZER

Turkey

It is the world's easiest and fastest installed wrought iron system. You can also choose the shape you want among 1500 different patterns from the catalogue. Our products are galvanized as pre-treatment and do not rust. It is painted with static powder paint in the color you want and sent ready for assembly.

Request for a quote

BASAK LAZER

Turkey

You can examine our fiber laser productions. Please contact us for detailed information and offer.

Request for a quote

BASAK LAZER

Turkey

Any type of metal sheet laser cutting service is offered. Laser cutting service is offered for stainless steel plate, copper plate, ST series plate, aluminum plate. We laser cut your drawings into metal sheets in dwg or dxf format. We also offer technical drawing service. We offer laser cutting services by converting your sketches into technical drawings.

Request for a quote

BASAK LAZER

Turkey

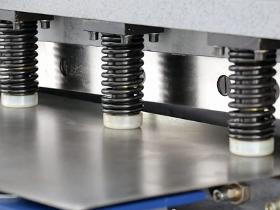

Abkant Twisting is a manufacturing equipment used in sheet metal forming, which can bend the sheet metal raw material and put it into the desired form. Abkant Twisting takes shape by pressing between two molds, and the molds used may vary according to the customer's request and may increase or decrease in this variability. Advantages of Abkant Twisting More than one bending can be produced in succession with Press Brake Twisting Manual and fast stop settings Twisting speed can be adjusted Entering the desired dimensions on the panel

Request for a quote

BASAK LAZER

Turkey

We can shape metal materials with our press brake machine with a capacity of 380 tons. We can shape your aluminum, stainless steel and ST series metal sheets in the desired form.

Request for a quote

BASAK LAZER

Turkey

Please contact us for detailed information and offer.

Request for a quote

BASAK LAZER

Turkey

In our factory, welded production can be made in line with the needs of our customers. We can prepare projects for our customers' production needs and produce them.

Request for a quote

BASAK LAZER

Turkey

Please contact us for detailed information and offer.

Request for a quote

BASAK LAZER

Turkey

Argon welding is the word “Tungsten Inert Gas” that gives the welding method its name. Welding is also called the initials of this word and is referred to as TIG welding. The heat to perform the welding process is generated between the electrodes made of tungsten metal, which has a very high melting point, and the parts to be welded. The welding zone is protected by argon or helium gas sent from a nozzle surrounding the electrode. The electrodes used in the Tig (argon) welding method allow to join the welded material by melting, without melting themselves. When deemed necessary, additional welding rods are delivered to the welding area by the welder or by automatic wire feeding devices, as in oxy gas welding. Argon gas is generally used as a shield in argon welding. Argon gas is a noble gas, so it does not react and provides strong protection. It optimizes the ignition characteristics and stability of the arc

Request for a quote

BASAK LAZER

Turkey

Aluminum is a light, thin metal that is very commonly used in welding shops. With this metal, welding must be done at low temperatures, otherwise pores will form in your materials. Aluminum is highly reactive, so it forms an oxide layer when exposed to air. This oxide is a barrier to welding. Before welding you need to remove the oxide layer using a wire brush. Each different type of weld requires different equipment and techniques, but when you apply everything involved, your aluminum welds look clean and smooth and are very durable.

Request for a quoteManufacturer/ Producer

Sanayi Mah. izmit Sanayi Sitesi, 9.

Cad. 301 blok no:9

41100 Kocaeli - Turkey